doc.000 012018 6/7

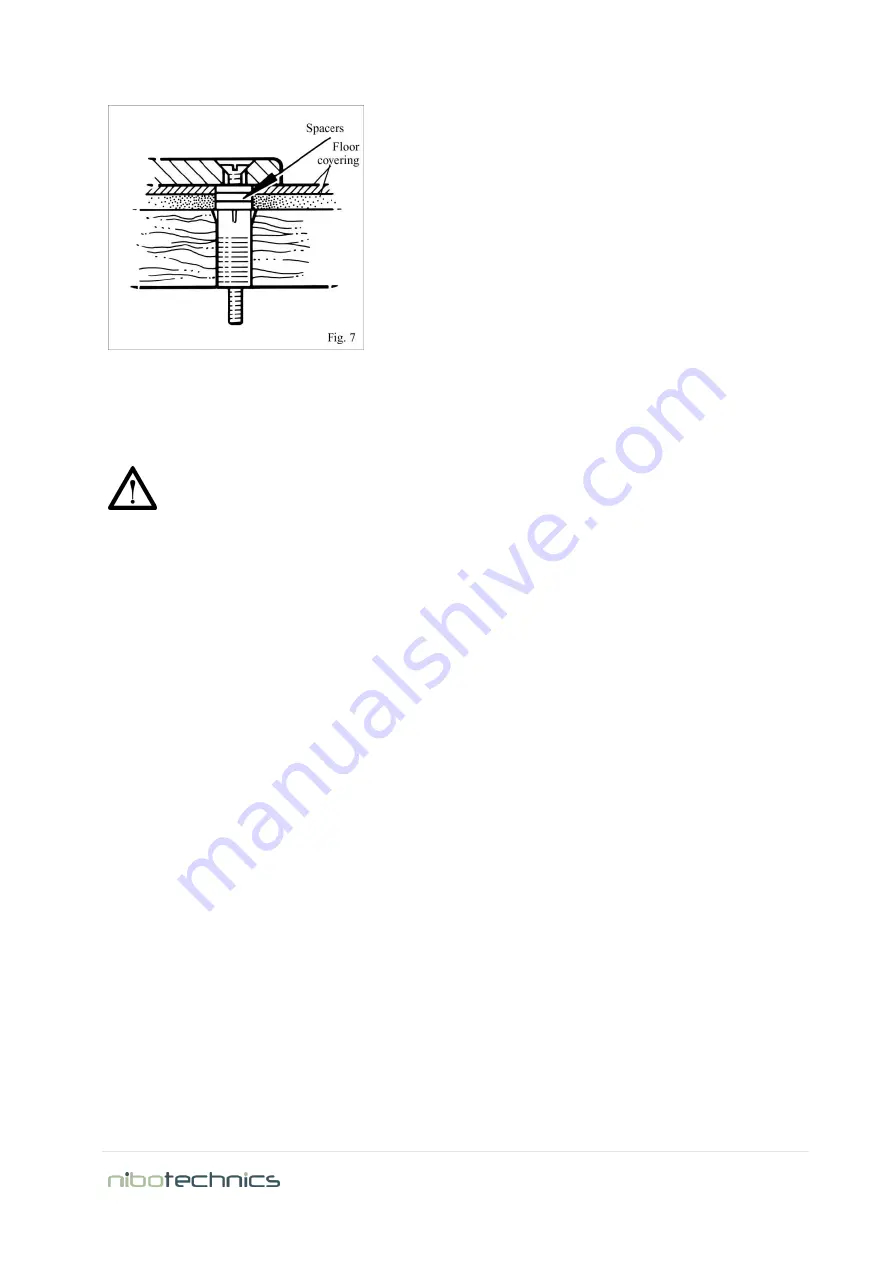

If a wooden floor is fitted with a floor covering eg. hardboard,

tiles, carpet, plastic flooring etc, the expansion anchor should

be inserted so it's top face is flush with the original wooden

floor. (see Fig 7)

The

resulting

gap

between

the

top

of

the

anchor/floorboarding and the finished floor level (tip surface

of floor covering) must be made up using the spacers

supplied.

Continuation (for concrete and wooden floors)

Position the base over the nylon plugs/expansion anchors and secure with the screws, as shown in

Figs. 4 and 5. Tighten the screws to form a rigid fixing.

Ensure all bolts and screws are fully

tightened on the unit and base.

Re-position the elevating unit and chair into the base plate socket.

Check that the base is securely fixed by putting your weight on the outside of the chair.

Rotate the chair and test in several positions.

With the elevating unit adjustment plunger inserted into the top hole of the base plate socket.

Position the chair over the bath and wind the handle until the chair is at its lowest position.

Support the jacking tube by holding where the curved chair support arm joins it (a second person may

be required for this operation) press in the adjustment plunger and slide the complete jacking unit

down in the base socket until the correct chair position has been attained (see Fig. 2). Release the

plunger into the next highest hole in the base socket.

When the Autolift electric has been installed, before it is used it must be thoroughly examined and load

the maximum safe working load (SWL) (shown on the rating label attached to the support arm).

When it has been inspected and load tested satisfactorily your Autolift electric is then ready for use.

Aftercare (see also Autolift electric operating instruction booklet)

UK HOISTS ONLY: A thorough examination of the Autolift electric, load testing of the base fixings at

the specified load (x 1,5 SWL) and checking for soundness and/or deterioration of the flooring material

in the vicinity of the Autolift electric must be carried out regularly every six months to conform to the

mandatory LOLER (Lifting Operations and Lifting Equipment Regulations 1998) examination and also

at the annual service.

NON UK HOISTS ONLY: A thorough examination of the Autolift electric, load testing of the base

fixings at the specified load (x 1,5 SWL) and checking for soundness and/or deterioration of the

flooring material in the vicinity of the Autolift electric must be carried out regularly every six months and

also at the annual service.

If the Autolift electric has to be removed for any reason then has to be re-installed in the same

position, the fixing holes and surrounding area should be carefully inspected. If the fixing holes are

enlarged or distorted or the surrounding area has deteriorated or been damaged do not install at the

same position until the fault/s has been rectified.

Summary of Contents for Autolift electric

Page 1: ...Installation instructions...