2

– English

GENERAL WARNINGS: SAFETY - INSTALLATION - USE (original instructions in Italian)

ATTENTION

Important safety instructions. Follow all instructions as improper installation may cause serious damage

ATTENTION

Important safety instructions. It is important for you to comply with these instructions for your own and other people’s

safety. Keep these instructions

•

Before commencing the installation, check the “Technical characteristics” (in this manual), in particular whether this product is suitable for

automating your guided part. If it is not suitable, DO NOT continue with the installation

•

The product cannot be used before it has been commissioned as specified in the chapter on “Testing and commissioning”

ATTENTION

According to the most recent European legislation, the implementation of an automation system must comply

with the harmonised standards provided by the Machinery Directive in force, which enables declaration of the

presumed conformity of the automation. Taking this into account, all operations regarding connection to the

electricity grid, as well as product testing, commissioning and maintenance, must be performed exclusively by a

qualified and skilled technician!

•

Before proceeding with the installation of the product, check that all the materials are in good working order and suited to the intended ap-

plications

•

This product is not intended to be used by persons (including children) whose physical, sensory or mental capacities are reduced, or who lack

the necessary experience or skill

•

Children must not play with the appliance

•

Do not allow children to play with the fixed control devices of the product. Keep the remote controls away from children

ATTENTION

In order to avoid any danger from inadvertent resetting of the thermal cut-off device, this appliance must not be

powered through an external switching device, such as a timer, or connected to a supply that is regularly powered

or switched off by the circuit

•

Provide a disconnection device (not supplied) in the plant’s power supply grid, with a contact opening distance permitting complete discon

-

nection under the conditions dictated by overvoltage category III

•

Handle the product with care during installation, taking care to avoid crushing, denting or dropping it, or allowing contact with liquids of any

kind. Keep the product away from sources of heat and naked flames. Failure to observe the above can damage the product, and increase the

risk of danger or malfunction. Should this happen, stop installation immediately and contact Customer Service

•

The manufacturer assumes no liability for damage to property, items or persons resulting from non-compliance with the assembly instructions.

In such cases the warranty for material defects is excluded

•

The weighted sound pressure level of the emission A is lower than 70 dB(A)

•

Cleaning and maintenance to be carried out by the user must not be carried out by unsupervised children

•

Before working on the system (maintenance, cleaning), always disconnect the product from the mains power supply

•

Check the system periodically, in particular all cables, springs and supports to detect possible

imbalances, signs of wear or damage. Do not use, if repairs or adjustments are necessary, since installation failure or an incorrectly balanced

automation may cause injury

•

The packing materials of the product must be disposed of in compliance with local regulations

•

When operating a biased-off switch, make sure that other persons are kept away

•

When operating the gate, keep an eye on the automated mechanism and keep all bystanders at a safe distance until the movement has been

completed

•

Do not operate the product if anyone is working nearby; disconnect its power supply before permitting such work to be done

•

If the power cable is damaged, it must be replaced by the manufacturer or by an appointed servicing company or similarly qualified person in

order to prevent any form of risk

INSTALLATION WARNINGS

•

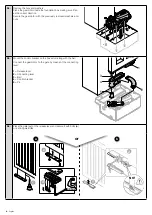

Prior to installing the drive motor, check that all mechanical components are in good working order and properly balanced, and that the au

-

tomation moves correctly

•

If the gate or door being automated has a pedestrian gate, then the system must include a control device that will inhibit the operation of the

motor when the pedestrian gate is open

•

Make sure that the control devices are kept far from moving parts but nonetheless in a visible position. Unless a selector is used, the control

devices must be installed at a height of at least 1.5 m and must not be accessible

•

That windows, having a gap exceeding 200 mm when open, are to be closed using a biased-off switch if the opening movement is controlled

by a fire-sensing system

•

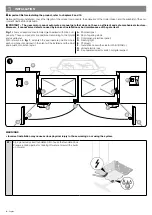

Ensure that entrapment between the driven part and the surrounding fixed parts due to the opening movement of the driven part is avoided

•

Permanently fix the label concerning the manual release adjacent to its actuating member

• After installing the

drive motor, make sure that the mechanism, protective system and all manual manoeuvres operate properly

Summary of Contents for BFAB5024

Page 2: ...2 English...

Page 16: ......