English –

5

English

At this point it is possible to install the accessories that belong to the system:

for photocells PH200 > Par. 3.6 (Fig. 6) - for flashing light FL200

> Par. 3.7 (Fig. 7). For other optional accessories, consult the respective instruction manuals.

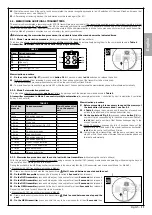

3.6 - INSTALLING THE PHOTOCELLS model PH200 (Fig. 6a - 6b)

The photocells can be mounted on the wall as described below (fig. 6a), or inside the gearmotor (fig. 6b); for this type of installation,

consult the instruction manual of the photocells.

• position each photocell 40/60 cm above the ground • position them on the opposite sides of the zone to be protected • position

them as close as possible to the gate (maximum distance = 15 cm) • a tube for passing the cables must be present in the fastening point

• orient the TX transmitter towards the central zone of the RX receiver (allowed misalignment: maximum 5°)

For the installation procedure see

Fig. 6a - 6b.

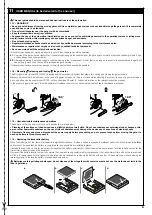

3.7 - INSTALLING THE FLASHING LIGHT model FL200 (Fig. 7)

• The

flashing light must be positioned near the gate in a clearly visible position. It can be fasted to a horizontal or vertical surface.

•

For connection to the Flash terminal, no polarity needs to be observed; instead for connection of the shielded aerial cable, it is necessary to connect

the cable and sheath as shown in

Fig. 8

.

Choose the most suitable position in which to install the flashing light: it must be positioned near the gate in a clearly visible position. It can be fasted

to a horizontal or vertical surface.

For the installation procedure see

Fig. 7

.

PH200

FL200

4

ELECTRICAL CONNECTIONS

Step

C

4.1 - ELECTRICAL CONNECTION TO THE CONTROL UNIT (Fig. 8)

01.

Perforate the rubber membrane and insert the cables necessary to connect the various devices (

Phase 01 - Fig. 8

): leave the cables at least

40–50 cm long and secure them with cable ties (

Phase 02 - Fig. 8

).

02.

Connect the various devices of the kit and any other components designed for being used on the system (optional and not included in the pack-

age) (

Phase 03 - Fig. 8

):

It is not necessary to observe any polarity, with the exception

of the shielded aerial cable which must be connected with

the cable and sheath as shown in

Phase 03 - Fig. 8

4.2 - POWER SUPPLY CONNECTION

CAUTION! – The final connection

of the system to the mains power or replacement of the cable supplied MUST be performed exclu-

sively by a qualified and electrician, in compliance with local safety standards and the following instructions.

• For operational and programming tests of the automation

, use the cable supplied, inserting the plug into an electrical socket. If the socket is a

long way from the automation, an extension may be used in this phase.

• For the testing and commissioning phase of the automation

, it is necessary to connect the control unit permanently to the mains power supply,

by replacing the supplied cable. To connect the cable to the gearmotor’s control unit, proceed as described below:

01.

Make sure that the gearmotor plug is not plugged into the wall socket.

02.

Disconnect the power cable from the gearmotor’s power supply terminal (

Fig.10

).

03.

Loosen the collar and remove the power cable: replace it with the permanent power cable.

04.

Connect the power cable to the gearmotor’s power supply terminal (

Fig. 11)

.

05.

Tighten the collar to secure the electric cable.

06.

Before closing the gearmotor’s cover (

Fig. 9

) it is possible to programme the control unit (see Chapter 5).

10

11