6

Door sensor:

this is an intruder sensor designed to protect doors or windows, and signals opening of the latter when the magnet is moved away from the

sensor body. The detector is normally mounted on the fixed section of the frame to be protected, on the side opposite the hinge, while the magnet is fitted

on the movable section. To increase protection, a second sensor with an NC or pulse type contact can be connected to a terminal (cable detector for rolling

shutters). This sensor also has an NO input, which can be used, for example, to connect a flooding sensor.

Sensor with vertical curtain lens:

this is an intruder detector designed to protect doors or windows; thanks to its curtain lens it signals the movement of

persons present only within the close range in front of the sensor (

fig. 4

).

The sensor can be “ceiling-mounted”, at the top centre of a door or window (normally between the window and shutter/blind) and in an area protected

against adverse weather conditions. The sensor is fitted with a terminal for connection of a second sensor with an NC or pulse type contact (cable detector

for rolling shutters). This ensures increased protection, optimising coverage of the area to be protected.

Volumetric sensor:

this is an intruder detector designed for the protection of rooms; it signals the movement of persons in the protected area. The sensor can

be mounted on a wall, in a corner with the special adaptor and can be set at different angles thanks to the articulated support (accessory not supplied).

Sensor operation is based on the detection of movement of heat-emitting bodies; for this reason, and to avoid improper alarm activation, avoid installation

in points subject to currents of hot or cold air. If the sensor is active and animals (hot-blooded) use the room, a suitable position and angle should be select-

ed to avoid detection below 50-70 cm from the ground (

fig. 5

); reduce sensor sensitivity if necessary.

The sensor is fitted with a terminal for connection of a second sensor with an NC or pulse type contact (cable detector for rolling shutters). This ensures

increased protection, optimising coverage of the area to be protected.

Volumetric sensors for large environments:

normal volumetric sensors have a sensitive range that is able to cover most standard-size rooms. In the case

of large rooms, special sensors are available with surface area coverage of up to 12 m with 120° opening. This type of sensor has a provision to adjust sen-

sitivity to enable precision settings according to the dimensions of the protected area.

Dual technology sensors:

these are intruder detectors designed for the protection of rooms; they use 2 different technologies (infrared and microwave) to

detect the movement of persons in the protected area. Infrared technology detects heat emitted by bodies, while microwave technology (Doppler effect)

detects the movement of objects (also cool). The combination of the two technologies achieves maximum efficiency with the minimum risk of improper

alarms.

Sensors for outdoors:

sensors are usually designed for protected indoor environments. These operate correctly within a relatively restricted temperature

range and are not completely protected against rain. Special sensors are available for outdoor use, with a temperature range from -25 to +50°C and com-

plete protection against adverse weather conditions. All these sensors have a provision to adjust sensitivity, to enable precision settings according to the

dimensions of the protected area and the avoidance of improper alarms caused, for example, by normal moving objects (tree branches), small animals,

insects etc.

Glass breakage sensor:

this sensor detects the breakage of glass (normal glass, double glazing). The detector is fitted with a microphone specially tuned

to recognise the specific noise of glass when it breaks; therefore take great care as the sensor may detect other events that produce a similar noise (for

example a tumbler falling and breaking on the floor). Activation of this sensor is only recommended if there are no persons in the relative zone who could pro-

duce similar sounds.

Also appliances able to generate sudden pressure surges in rooms (air conditioners, fans) may generate improper alarms.

Sound-absorbing materials (such as curtains and carpets) may reduce the sensitivity of the sensor.

The device is optimised with a factory-setting and may not be modified.

To ensure optimal detection, the device must be installed in rooms with an area of 20 to 30 square metres, at a distance of 3 to 6 m from the glass to be pro-

tected and at a height of approx. 2 m.

Installation is not recommended in areas with dimensions of less than 10 m

2

, in excessively humid environments (bathrooms or kitchens) and in garages with

large metal doors. These conditions can prove critical and may generate improper alarms.

Fine powder detector:

this is a detector of fine combustion powder (mist or smoke effect) designed for residential applications. A photodiode detects opac-

ity of the air and signals the alarm directly on site (by means of a buzzer) and also via radio to the control unit. It is a sensor able to detect this event on a max-

imum surface area of 6 x 6 m, and must be positioned on the ceiling at the centre of the area to be protected. Smaller rooms that are not square, such as

corridors, require the use of more than one detector.

Flooding sensor:

this sensor detects flooding caused by water leaks. It is wall-mounted, perfectly flush with the floor surface (the internal sensor is raised

by approx. 1 mm from the ground) and positioned in the zone most subject to the risk of water leaks, such as next to a sink or washing machine.

If the floor is not level, the sensor should be placed at the lowest point of the room. The sensor is connected to the NO input of one of the compatible detec-

tors (for example HSDID11).

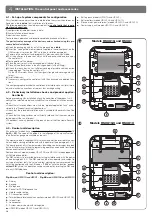

TABLE 3

4

12

3

4

5

6

8

9

10

7

2,5

1,5

1

12

3

4

5

6

8

9

10

7

0,5

2

2,5

1,5

1

0,5

2

5

Summary of Contents for HSCU1

Page 1: ...Nice HSCU1 Instructions and warnings for installation and use Home security control unit 0682 ...

Page 2: ......

Page 14: ...12 b a 11 12 13 CRACK CRACK CRACK 14 x 3 x 1 a 15 ...

Page 15: ...18 only for models HSCU1G and HSCU1 x 4 19 x 3 a 16 x 3 17 13 ...

Page 32: ...42 x 4 44 only for models HSCU1GC and HSCU1C 43 only for models HSCU1G and HSCU1 30 ...

Page 39: ......