EN

14

– English

7.4 - Diagnostics

Some devices are able to emit signals that serve to recognise their state of

operation or possible faults.

7.4.1 - Signals of control unit

The LEDs of the terminals and the keys on the control unit emit special signals

both to indicate normal operation and possible faults. Tables

12

and

13

describe the cause and solution for each type of signal.

E

TABLE 12 - Terminal LEDs on control unit

Led Bluebus

Cause

Solution

Off

Fault

Check for presence of the power supply; check that the fuses are not

blown; in this case, identify the cause of the fault and then replace with

versions with the same specifications.

On

Serious fault

This indicates a serious fault; try switching off the control unit for a few

seconds; if the condition persists there is a fault and the electronic

board needs to be replaced.

1 flash per second

All OK

Normal operation of control unit.

2 quick flashesi

Input status variation

A variation to the status of the inputs SS, STOP, OPEN, CLOSE,

activation of the photocells, or when the radio transmitter is used,

is normal.

Series of flashes separated by

Various

This is the same signal of 1 second as on the flashing light

(See table 15).

Led STOP

Cause

Solution

Off

STOP input activation

Check the device connected to the STOP input

On

All OK

STOP input active

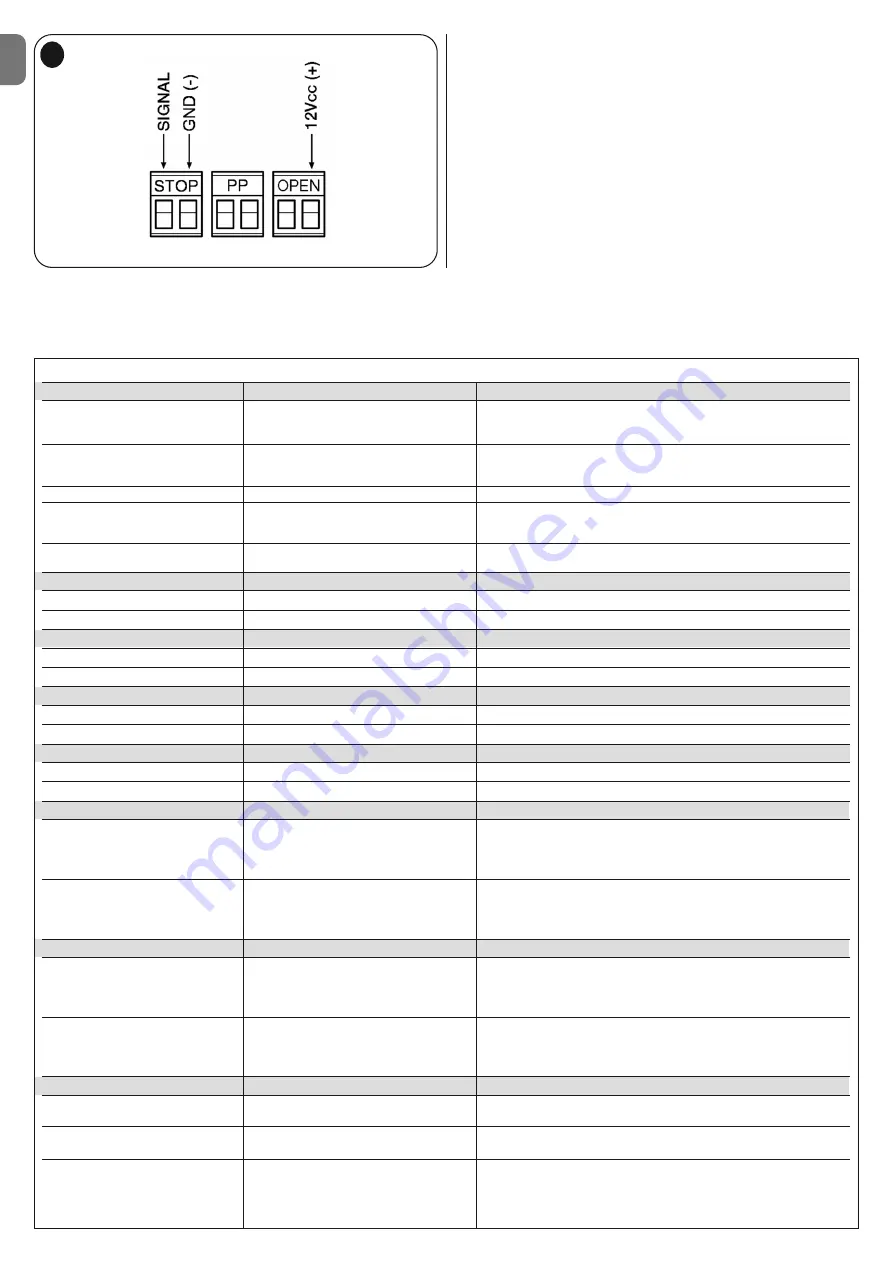

Led PP

Cause

Solution

Off

All OK

S.S. Input not active

On

S.S. input activation

Normal if the device connected to the S.S. input is active

Led OPEN

Cause

Solution

Off

All OK

OPEN input not active

On

OPEN input activation

Normal if the device connected to the OPEN input is active

Led CLOSE

Cause

Solution

Off

All OK

CLOSE input not active

On

CLOSE input activation

Normal if the device connected to the CLOSE input is active

FC1 limit switch LED

Cause

Solution

Off

Limit switch activation

- If the parameter “Standard motor rotation direction” is set, the pole

is in the total closing position.

- If the parameter “Inverted motor rotation direction” is set, the pole is

in the total opening position.

On

Limit switch not activated

- If the parameter “Standard motor rotation direction” is set, the pole

is in a position other than the total closing position.

- If the parameter “Inverted motor rotation direction” is set, the pole is

in a position other than the total opening position.

FC2 limit switch LED

Cause

Solution

Off

Limit switch activation

- If the parameter “Standard motor rotation direction” is set, the pole

is in the total opening position.

- If the parameter “Inverted motor rotation direction” is set, the pole

is in the total closing position.

On

Limit switch not activated

- If the parameter “Standard motor rotation direction” is set, the pole

is in a position other than the total opening position.

- If the parameter “Inverted motor rotation direction” is set, the pole is

in a position other than the total closing position.

Led encoder

Cause

Solution

Off

The magnet is in front of the sensor

If there is no manoeuvre in progress it is normal, otherwise there is a

fault in the encoder or the cable is not connected properly

On

The magnet is not in front of the sensor

If there is no manoeuvre in progress it is normal, otherwise there is

a fault in the encoder or the cable is not connected properly

Flashing light

Manoeuvre in progress

All OK if the manoeuvre is in progress; the flashing is proportional to

the speed

Note – During the execution of the manoeuvre, the flashing speed

could appear as LED on.

Summary of Contents for M3BAR

Page 2: ......

Page 26: ......

Page 30: ...II 4 3 b a c d g h f e c a b...

Page 31: ...III 5 6 MBAR a c d b...

Page 32: ...IV 90 8 9 MBAR a b c a b 7 a b...

Page 33: ...V 180 10 11 LBAR c a a b...

Page 34: ...VI 13 14 12 LBAR c a b...

Page 35: ...VII 15 16 18 17...

Page 36: ...VIII 19 20 21 23 22...

Page 37: ...IX 24 26 25 28 1 cm 27 29...

Page 38: ...X 33 34 30 31 32 c a b c a b...

Page 39: ...XI 35 36 37 45 38 a b a b c...

Page 41: ...XIII 42 43 44 STOP 45 46 LIGHT 47...

Page 42: ...XIV 48 49 50 a b c...

Page 43: ...XV 51 52 a b...

Page 44: ...XVI 53 a b c d e f g...

Page 46: ...XVIII F1 F1 F2 F2 55...

Page 47: ......

Page 48: ...ISTML BARR01 4865_07 10 2011 www niceforyou com Nice SpA Oderzo TV Italia info niceforyou com...