TABLE 17

Perimeter of the loop

Number of turns to be carried out

2 – 4 m

6

4 – 7 m

5

7 – 12 m

4

more than 12 m

3

Note

– If in the loop positioning place, below the floor, there are some metal

reinforcements, the inductivity of the loop is reduced. In this case, it is

necessary to add 2 turns to the twisting of the cable

EN

English –

17

able sheath.

The length of the twisted cable must be less than 20 m

.

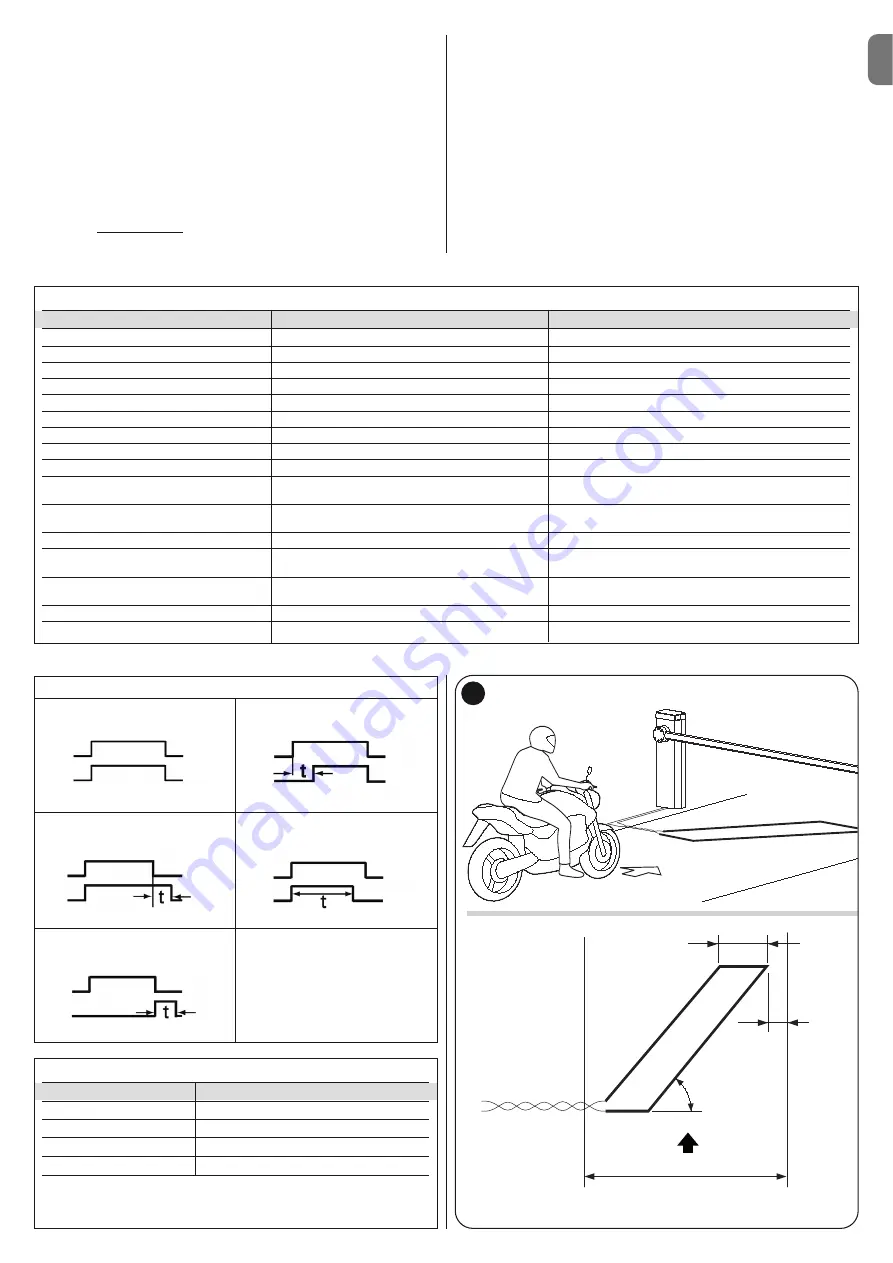

01.

After determining the size of the loop, dig a groove in the floor of a width =

8 mm and a depth = 30-50 mm (

fig. H

);

02.

Clean the groove and insert the loop, trying to compact it in a way to avoid

it moving;

03.

Carry out the number of turns of the loop depending on the perimeter, as

indicated in

Table 17

: use a 1.5 mm

2

unipolar isolated copper cable (

fig. H

);

04.

Before sealing the groove, check that the value of the inductive loop is

between 100 and 400 uH or, through the Oview programmer, check that

the value of the measured frequency (Parameter “Loop Frequency”) is

between 30 and100 KHz;

05.

Cover the loop with sand to protect it and then seal the groove with bitu-

men or resin for outdoor use (

fig. H

).

Important!

– The temperature of the

sealant must not exceed the maximum temperature admitted for the isola-

tion of the cable, otherwise a loss in isolation towards the earth may occur.

TABLE 15

Function

Values

Default

Loop 1 sensitivity

10 – 100%

90%

Loop 2 sensitivity

10 – 100%

90%

Loop power supply

on – off

on

Loop 1 active

on – off

on

Loop 2 active

on – off

on

Loop 1 operating mode

1 – 5

1

Loop 2 operating mode

1 – 5

1

Loop 1 permanence time

2 – 20 = always

20 = always

Loop 2 permanence time

2 – 20 = always

20 = always

Output function 1, 2, 3:

Active out (1,2,3) for loop 1

selectable

off

Output function 1, 2, 3:

Active out (1,2,3) for loop 2

selectable

off

Calibration [also carried out upon start-up]

on – off

Loop 1 activation mode*:

1 – 5

1

Loop 1 time

0 – 25 s

2s

Loop 2 activation mode*:

1 – 5

1

Loop 2 time

0 – 25 s

2s

Loop 1 frequency display

0 - 127000

-

Loop 2 frequency display

0 - 127000

-

G

approximately 0,8 m

Direction of travel

0,2 m

Route

45°

06.

The electric cables must be connected to the

Loop1

(

fig. I

) and

Loop2

(

fig. L

) terminals. The Loop2 terminal presents 2 connection possibilities

(

fig. L

); based on the type of connection used, it varies the working fre-

quency of the loop.

Important!

– If Loop1 is positioned near Loop2 and both work at the

same frequency (or almost), interference could be generated; in this case,

it is necessary to change the connection to Loop2 terminal.

TABLE 16

1

loop

relay

loop

relay

loop

relay

loop

relay

loop

relay

2

3

4

5

Summary of Contents for M3BAR

Page 2: ......

Page 26: ......

Page 30: ...II 4 3 b a c d g h f e c a b...

Page 31: ...III 5 6 MBAR a c d b...

Page 32: ...IV 90 8 9 MBAR a b c a b 7 a b...

Page 33: ...V 180 10 11 LBAR c a a b...

Page 34: ...VI 13 14 12 LBAR c a b...

Page 35: ...VII 15 16 18 17...

Page 36: ...VIII 19 20 21 23 22...

Page 37: ...IX 24 26 25 28 1 cm 27 29...

Page 38: ...X 33 34 30 31 32 c a b c a b...

Page 39: ...XI 35 36 37 45 38 a b a b c...

Page 41: ...XIII 42 43 44 STOP 45 46 LIGHT 47...

Page 42: ...XIV 48 49 50 a b c...

Page 43: ...XV 51 52 a b...

Page 44: ...XVI 53 a b c d e f g...

Page 46: ...XVIII F1 F1 F2 F2 55...

Page 47: ......

Page 48: ...ISTML BARR01 4865_07 10 2011 www niceforyou com Nice SpA Oderzo TV Italia info niceforyou com...