6

– English

English

INSTALLATION: COMPONENT ASSEMBLY AND CONNECTION

––– STEP 5 –––

IMPORTANT!

- The following assembly steps illustrate installation of the MAES-

TRO300M / MAESTRO300C gearmotor.

- For correct system operation it is necessary to supply mechanical

stops, on the ground or wall, positioned at the maximum Opening and

Closing points of the door.

Note

- These end stops are not included in

the kit and do not form part of the Nice Home product range.

WARNINGS

• Incorrect installation may cause serious physical injury to those

working on or using the system.

• Before starting automation assembly, carry out the preliminary

checks as described in STEP 3

.

5.1 - MAESTRO300C and MAESTRO300M GEARMOTOR

INSTALLATION

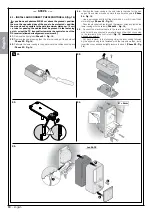

01.

Measure distance “

B

” (

fig. 6

).

02.

Move the leaf to the desired maximum opening position, and check

whether the angle value found falls within the values listed in

Graph 4

.

03.

As shown in

fig. 4

, using value “

B

” and the opening angle, determine

value “

A

” (

fig. 7

).

Example: if “

B

” is 100mm and the angle required is

equal to 100°, the distance “

A

” is around 180 mm

.

04.

Affix the

mounting bracket of the gearmotor to the wall, in a hori-

zontal position, as shown in

fig. 8-1, 8-2, 8-3

: use suitable anchors,

screws and washers (not supplied);

05.

Affix the gearmotor to the previously mounted bracket, as shown in

fig. 8-4, 8-5

: us the M6x100 screw supplied;

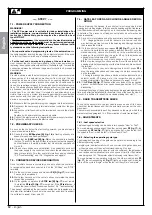

06.

Now, affix the

curved arm to the arm using the pin and the ringed

stop (

fig. 8-6

)

; then affix the mounting bracket for the gate leaf to the

curved arm, using the pin and ringed stop (

fig. 8-6

);

07.

Manually release the gearmotor (

fig. 8-7

), see paragraph 11.3;

08.

Now, determine where to affix the bracket to the gate leaf, by extend

-

ing the gearmotor arms as far as possible (

fig. 8-8

): it is important to

position the bracket at the farthest point with respect to the position

of the gearmotor;

09.

Drill the leaf and affix the bracket, using suitable screws (not supplied)

(

fig. 8-9

);

10.

Before locking the gearmotor, adjust the opening mechanical stop

(paragraph 5.2).

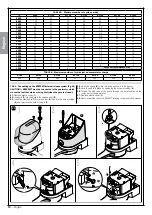

5.2 - ADJUSTING THE OPENING MECHANICAL LIMIT

SWITCH

If, in your installation environment, there are no mechanical stops placed

on the ground, designed to stop the wings of the gate at the end of their

opening movement, it is necessary to adjust the mechanical stop on the

bottom side of each motor, in the following manner:

01.

Manually move the gate leaves to the fully open position;

02.

Rotate the plastic disc, located on the lower part of the gearmotor,

bringing the slot below the arm into the position shown in

fig. 9-1

;

03.

Insert the end stop into the first available position: try to insert it as

shown in

fig. 9-2

(opening direction);

04.

Turn the disc so that the end stop does not fall, by bringing the slot

into the position shown in

fig. 9-3

; for a more precise adjustment,

turn the adjustment screws (

fig. 9-4

);

05.

If there is no closing ground stop present in the system, it is necessary

to repeat the process from point 01 to adjust the closing end stop;

06.

Finally, screw the nut holding the disc down fully (

fig. 9-5

) to ensure

that it cannot accidentally rotate.

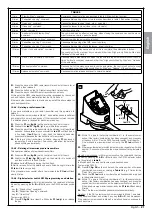

5.3 - MAESTRO300C and MAESTRO300M GEARMOTOR

CONNECTION

CAUTION! – All electrical connections must be made while discon-

nected from the grid and disconnected from the backup battery

(if any).

To make the electrical connections, remove the top cover of the gearmo-

tor as shown in

fig. 13-1

.

•

MAESTRO300C

: thread the cable through the appropriate duct locat-

ed on the back of the gearmotor, and make the electrical connections

as shown in

13-3

,

13-4

e

13-5

, richiudere il coperchio (

fig. 13-6

).

•

MAESTRO300C

: thread the cables through the appropriate duct

located on the back of the gearmotor, and make the electrical connec-

tions as shown in

fig. 12

, replace the cover.

Bearing in mind that:

01.

To facilitate connection operations, you can remove the terminals.

After having made the connections, insert the terminals back into

their dedicated seats.

02.

The MAESTRO300M cable is connected as shown in detail (

B

) in

fig.

12

.

03.

Remember that in order to avoid the risk of the two leaves colliding,

the MAESTRO300C command unit first commands the motor con-

nected to the M2 output to open, and then the motor connected to

M1, whilst during closing, the reverse happens. Then, make sure that

the (outer) terminal M1 is connected the motor that drives the leaf

resting on the mechanical stop, and terminal M2 to the top leaf.

If you are using only one motor (gate with only one leaf), connect it to

terminal M2, leaving terminal M1 free.

04.

The grey terminals (open) and red (stop) of the KS200KIT key selector

switch (optional accessory), are connected respectively to the grey

terminals (open) and red (stop) of the control unit. You do not need to

observe any polarity for the connection.

05.

If you are using an external antenna (optional accessory), you will need

to connect the control unit core and the screen of the shielded cable

as shown in detail (

A

) in

fig. 12

.

Summary of Contents for Maestro300

Page 2: ......

Page 10: ...8 Français Français 4 OK 3 NO 2 NO 1 180 2 2 180 1 9 10 11 1 3 4 5 2 ...

Page 28: ......

Page 36: ...8 English English 4 OK 3 NO 2 NO 1 180 2 2 180 1 9 10 11 1 3 4 5 2 ...

Page 54: ......

Page 62: ...8 Italiano Italiano 4 OK 3 NO 2 NO 1 180 2 2 180 1 9 10 11 1 3 4 5 2 ...

Page 80: ......

Page 88: ...8 Polski Polski 4 OK 3 NO 2 NO 1 180 2 2 180 1 9 10 11 1 3 4 5 2 ...

Page 106: ......

Page 119: ......