EN

4

– English

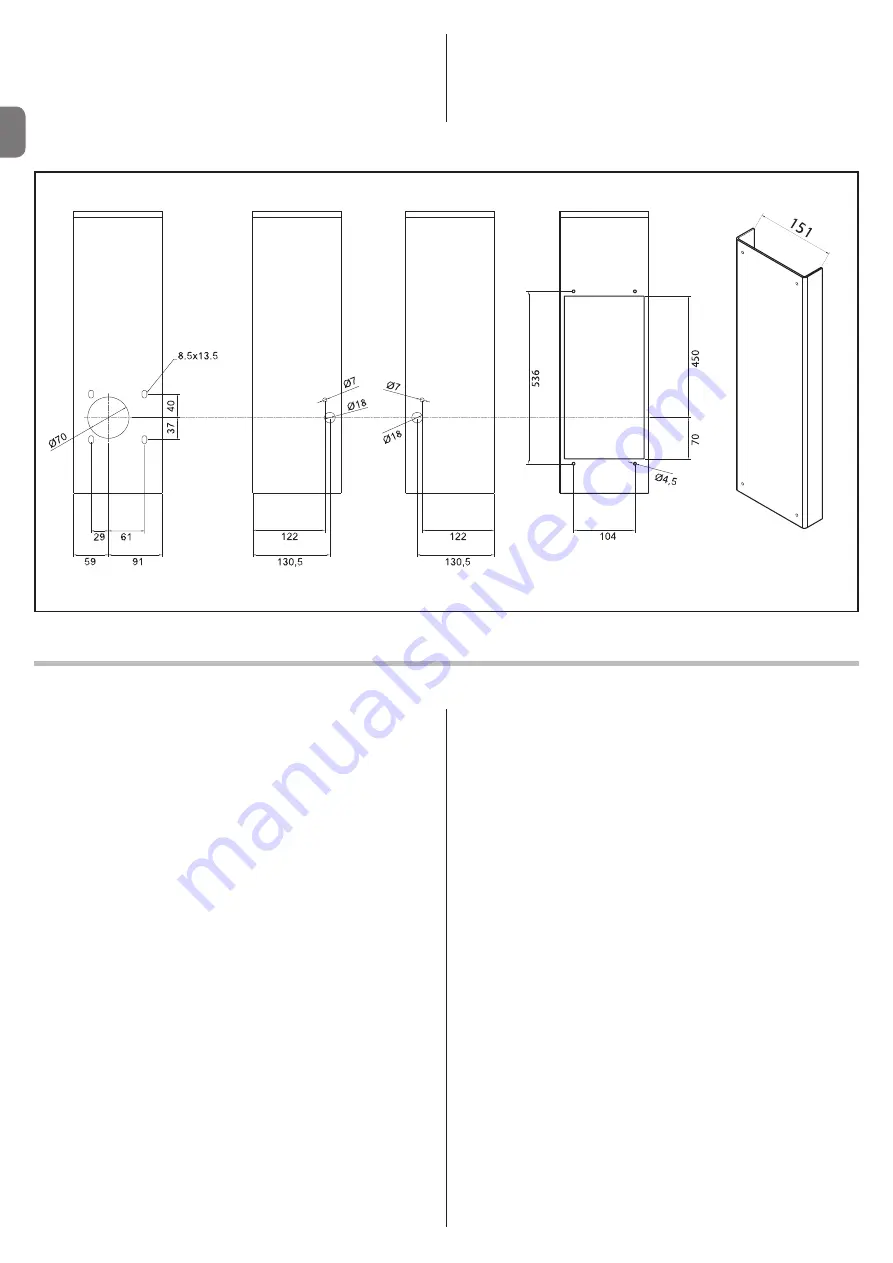

3.4 - Preparing the column for installation of the gearmotor

Warnings

- the column must be sealed at the top.

- The size of the hole for introduction of the gearmotor must be 520 x134 mm

Note – We recommend use of a lid such as the one shown in the illustration (

a

):

151 mm, internal measurement.

(

a

)

3.5 - Installation of gearmotor

WARNINGS

• Incorrect installation may cause serious physical injury to those wor-

king on or using the system.

• Before starting automation assembly, make the preliminary checks as

described in paragraphs 3.1 and 3.2

.

Before proceeding with installation, position the door halfway along its travel

and then anchor the gearmotor to the base (column). This ensures that the

mechanical limit switches are automatically adjusted correctly (Paragraph 3.6).

01.

Insert the lid on the release into the hole provided and anchor it in place

with the screw and washer provided (

fig. 3

)

02.

If the installation is not sufficiently easy, use the 2 dowels provided and fit

them into the slots at the bottom of the column (

fig. 4

); insert the gearmotor

in the column and align it with the slots provided (

fig. 5

);

03.

Remove the dowels and anchor the gearmotor in place with the M8 screws

provided (

fig. 6

).

Important

– You can adjust the height of the gearmotor

within a range of 5 mm;

04.

Insert the triangular pin in the release shaft seat (

fig. 7

). You can adjust the

overhang of the pin by adapting it to column width. Then check by inserting

the release wrench. Anchor it in place with the nut provided, being careful

to close it on the flat surface of the pin.

05.

At this point, if there is already a rack, adjust the mechanical limit switches

as described in point 3.6.

If the rack is to be installed, proceed as follows:

a)

Manually position the door at least 50 cm away from the limit switch stop

(during closing);

b)

Position the rack on the pin and check that it is perfectly aligned and

there are at least 1 to 2 mm of play between the pin and the rack;

c)

Manually put the door in the closing position (complete) and check that

the first bracket used to anchor the rack in place is aligned with the center

of the pin.

3.6 - Adjusting the mechanical limit switches

01.

Release the gearmotor with the key provided (refer to point 3.7);

02.

Then manually perform a complete Opening and Closing manoeuvre to

permit automatic regulation of the mechanical limit switches.

Important

–

During this maneouvre, check that the rack runs in alignment with the pin,

with a misalignment of maximum 5 mm, and that there is a play of 1÷2 mm

between pin and rack along its entire length (

fig. 8

);

03.

Lastly, manually position the door halfway along its travel and lock the

gearmotor in place with the key provided (refer to point 3.7).

3.7 - Manually releasing and locking the gearmotor

The gearmotor is equipped with a mechanical blocking system to enable man-

ual opening and closing of the gate.

These manual operations should only be performed in the event of a power

failure, malfunctions or during the installation procedures.

01.

Slide the disk covering the lock (

fig. 9

);

02.

Insert the key and turn it clockwise (90° -

fig. 10

);

03.

It is now possible to move the door into the desired position manually.

Slots

Summary of Contents for Naked Sliding NKSL400

Page 2: ......

Page 43: ...I 405 mm 131 mm 135 mm 1 3 4 5 b d c c h l b f m g i n e a E C F D C F A B 2...

Page 44: ...II b a b a c 5 mm 6 7 10 11 8 9...

Page 46: ...IV 14 15...

Page 48: ...VI 19 20 a b c d e...

Page 49: ...VII 21 22...

Page 50: ......

Page 51: ......