22

– ENGLISH

FURTHER INFORMATION

(Accessories)

9

9

FURTHER DETAILS (Accessories)

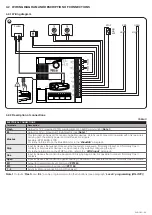

9.1 ADDING OR REMOVING DEVICES

Once the automation has been assembled, it is possible to add

or remove devices at any time. In particular, various types of de-

vices can be connected to the “

BlueBUS

” and “

STOP

” inputs,

as described in the following paragraphs.

m

After having added or removed devices, these must

be learned as described in the “Learning of other

devices” paragraph.

9.1.1 BlueBUS

BlueBUS is a technique that allows for connecting compatible

devices with only two wires which carry the electrical power and

the communication signals. All devices are connected in paral-

lel on the same 2 BlueBUS wires and without having to observe

the polarities; each device is recognised because it is assigned

a univocal address during the installation phase.

The following devices can be connected to the BlueBUS: photo-

cells, safety devices, control buttons, signalling lights, etc. The

control unit recognises all the connected devices individually

through an appropriate learning phase, and can detect all pos-

sible anomalies with absolute precision.

For this reason, whenever a device is connected to or removed

from BlueBUS, the learning phase must be carried out on the

control unit, as described in the “

”

paragraph.

9.1.2 STOP input

STOP is the input that causes immediate stoppage of the ma-

noeuvre followed by its brief reversal. Devices with output fea-

turing normally open “NO” and normally closed “NC” contacts,

as well as devices with 8.2 kΩ fixed resistor output, such as

sensitive edges, can be connected to this input.

As with the BlueBUS, the control unit recognises the type of

device connected to the STOP input during the learning phase

(see the “

” paragraph); subsequent-

ly the control unit gives a STOP command when it detects a

variation with respect to the recognised status.

Multiple devices, even of different types, can be connected to

the STOP input if suitable arrangements are made:

–

Any number of NO devices can be connected to each other

in parallel.

–

Any number of NC devices can be connected to each other

in series.

–

Two devices with 8.2 kΩ fixed resistor output can be connect-

ed in parallel; if there are more than 2 devices then they must

all be connected in cascade, with a single 8.2 kΩ terminating

resistor.

–

It is possible to combine two NO and NC contacts by placing

them in parallel, while also mounting a 8.2 kΩ resistor in series

with the NC contact (this also allows for combining 3 devices:

NA, NC and 8.2 kΩ).

a

If the STOP input is used to connect devices with

safety functions, only those devices with 8.2 kΩ

fixed resistor guarantee Category 3 safety against

faults in accordance with the EN 13849-1 standard.

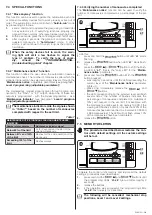

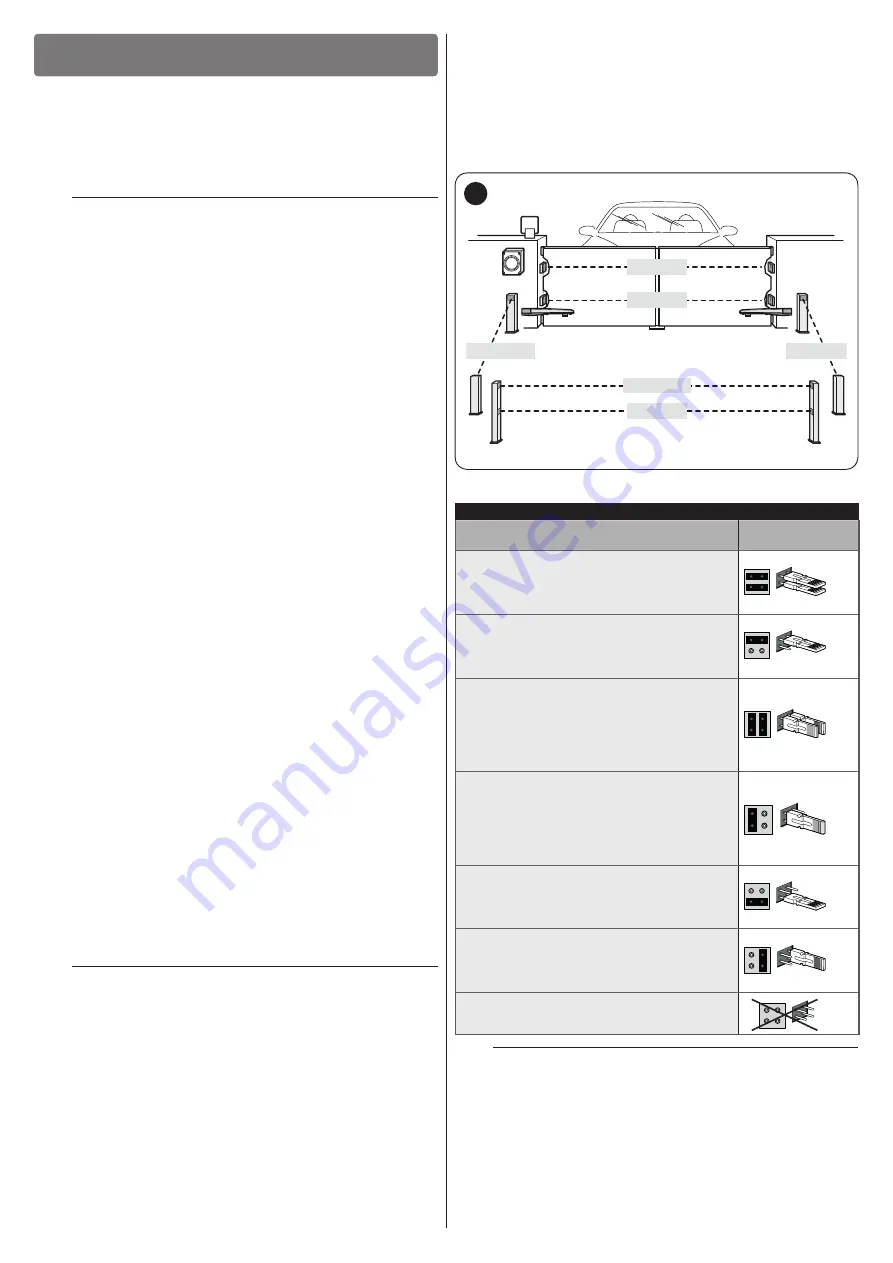

9.1.3 Photocells

To allow the control unit to recognise the devices connected

through the “BlueBUS” system, these devices must be ad-

dressed.

This operation can be carried out by correctly positioning the

electrical jumper present in each device (also refer to the in-

struction manual of each device). Shown below is an address-

ing diagram for photocells, based on their type.

FOTO 1

FOTO

FOTO II

FOTO 1 II

FOTO 2 II

FOTO 2

40

Table 10

PHOTOCELL ADDRESSES

Photocell

Position of the

jumpers

FOTO (PHOTO)

External photocell h = 50 activated during

the closing phase (stops and reverses the

gate’s movement)

FOTO II (PHOTO II)

External photocell h = 100 activated

during the closing phase (stops and

reverses the gate’s movement)

FOTO 1 (PHOTO 1)

Internal photocell h = 50 cm with

activation both during closing (stops

and reverses the movement) and during

opening (stops and restarts when the

photocell disengages)

FOTO 1 II (PHOTO 1 II)

Internal photocell h = 100 cm with

activation both during closing (stops

and reverses the movement) and during

opening (stops and restarts when the

photocell disengages)

FOTO 2 (PHOTO 2)

Internal photocell triggered during the

opening phase (stops and reverses the

gate’s movement)

FOTO 2 II (PHOTO 2 II)

Internal photocell triggered during the

opening phase (stops and reverses the

gate’s movement)

FOTO 3 (PHOTO 3)

CONFIGURATION NOT ALLOWED

m

At the end of the installation procedure, or after

photocells or other devices have been removed, the

learning procedure must be carried out (see para-