4

– ENGLISH

INSTALLATION

3

3

INSTALLATION

3.1 PRE-INSTALLATION CHECKS

a

The installation must be carried out by qualified

personnel in compliance with the current legisla-

tion, standards and regulations, and with the in-

structions provided in this manual.

Before proceeding with the product’s installation, it is necessary

to:

–

check the integrity of the supply

–

check that all the materials are in good working order and

suited to the intended use

–

make sure that the structure of the gate is suitable for being

automated

–

make sure that the weight and dimensions of the gate leaf

fall within the operating limits specified in the “

–

check that the installation location is compatible with the over-

all clearance of the product (see “

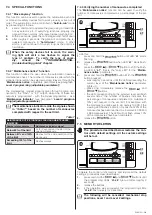

Figure

“)

–

make sure that there is enough space in the installation loca-

tion for the gearmotor’s arm to rotate fully (see “

Figure

MIN 400 mm

2

–

verify that there are no points of greater friction during the

opening and closing movements along the entire gate path

–

verify that the overrun mechanical stops are sturdy enough

and that they do not deform even if the leaf should strike them

forcefully

–

verify that the gate leaf is well balanced: it must not move by

itself when left in any position

–

make sure that the installation area is not subject to flooding; if

necessary, the product must be installed appropriately raised

above ground level

–

verify that the area where the gearmotor is installed allows for

unlocking the latter and manoeuvring easily and safely

–

verify that the mounting positions of the various devices are

protected against impacts and that the mounting surfaces are

sufficiently sturdy

–

prevent any parts of the automation from being immersed in

water or other liquids

–

keep the product away from heat sources and open flames

and acid, saline or potentially explosive atmospheres; these

may damage the product and cause malfunctions or danger-

ous situations

–

if there is an access door in the gate, or within its range of

movement, make sure that it does not obstruct the gate’s nor-

mal path; install an appropriate interlock system if necessary

–

connect the control unit to an electricity supply line equipped

with a safety earthing system

–

connect the gate to the earthing device in accordance with

the current legislation

–

include a device on the electric power line ensuring complete

disconnection of the automation from the grid. The disconnec-

tion device must have contacts with a sufficient gap to ensure

complete disconnection, under the Category III overvoltage

conditions, in accordance with the installation instructions.

Should it be necessary, this device guarantees fast and safe

disconnection from the power supply; it must therefore be po-

sitioned in view of the automation. If placed in a non-visible

location, it must have a system that blocks any accidental on

unauthorised reconnection of the power supply, in order to

prevent dangerous situations. The disconnection device is not

supplied with the product.

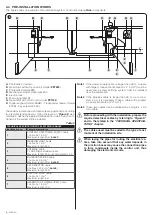

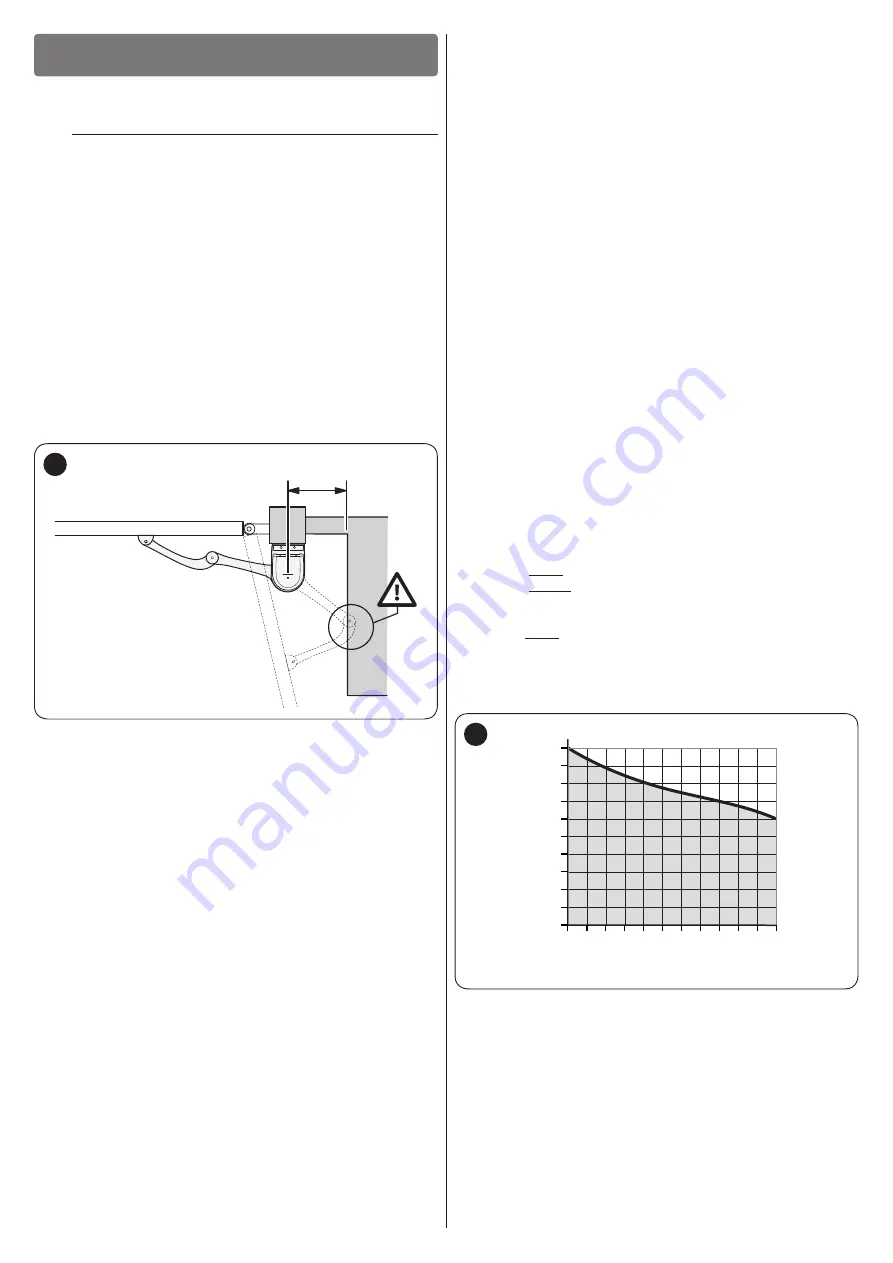

3.2 PRODUCT USAGE LIMITS

Carry out the following checks before installing the gearmotor:

–

check that the leaf to be automated falls within the specified

values (see “

Figure

“)

–

maximumwidth of the leaf: 2,0 m (with weight up to 200 kg)

–

maximumweight of the leaf: 250 kg (with width up to 1 m)

–

verify the limits for the values shown in the “

–

minimumwidthof the space reserved for the gearmotor’s in-

stallation: 170 mm

–

the arm’s fixing bracket must be attached to a sturdy point of

the leaf (for example, the frame), to guarantee solid and safe

anchoring.

150

1,0 1,2 1,4 1,6 1,8 2,0

175

125

200

225

250

peso anta (kg)

larghezza anta (m)

Leaf weight (kg)

Width of the leaf (m)

3