8

3.3) Fixing of the limit switch bracket on versions with inductive limit switch

8.

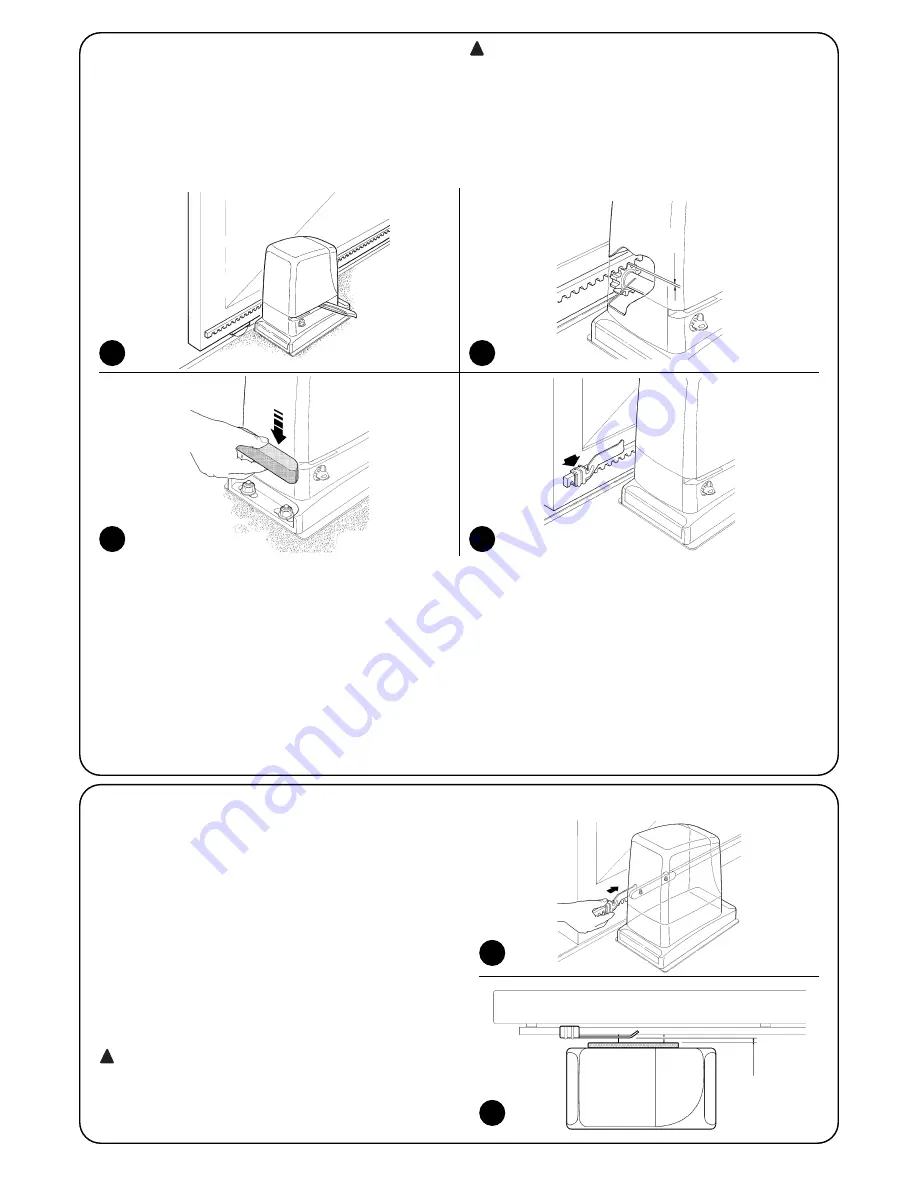

Slide the leaf, using the pinion as a reference point for the securing

the other elements of the rack.

9.

Cut away the excess section of the rack.

10.

Open and close the gate several times and make sure that the rack

is aligned with the pinion with a maximum tolerance of 5 mm. More-

over, check that the play of 1÷2 mm has been respected along the

entire length between the pinion and the rack.

11.

Thoroughly tighten the two fixing nuts of the gearmotor making

sure it is well secured to the ground. Cover the fixing nuts with the

relative caps as shown in figure 10.

12.

Fix the limit switch bracket as described below (for versions

RUN1800P and RUN2500P, fix the bracket as described in para-

graph “3.3 Fixing of the limit switch bracket on versions with induc-

tive limit switch”):

• Manually place the leaf in the open position leaving at least 2-3

cm from the mechanical stop.

• Slide the bracket along the rack in the opening direction until the

limit switch cuts-in. Then bring the bracket forward by at least 2

cm and secure it to the rack with the appropriate stud bolts, as

shown in fig. 11.

• Perform the same operation for the closure limit switch.

13.

Secure the gearmotor as described in the paragraph “Release and

manual movement” in the Chapter “Instructions and Warnings for

Users”.

8

9

10

11

6.

Release the gearmotor as shown in “Release and manual move-

ment” paragraph in the Chapter “Instructions and Warnings for

users of the RUN gearmotor”.

7.

Open the leaf up completely and place the first piece of the rack

on the pinion. Check that the beginning of the rack corresponds

to the beginning of the leaf, as shown in Figure 8. Leave 1÷2 mm

play between the rack and the pinion, then fasten the rack to the

leaf using suitable means.

In order to prevent the weight of the leaf from affecting

the gearmotor, it is important that there is a play of 1÷2

mm between the rack and the pinion as shown in Figure 9.

!

1÷2mm

The limit switch bracket must be fixed as described below for the

RB600P and RB1000P versions that utilise the inductive limit switch.

1.

Manually place the leaf in the open position leaving at least 2-3

cm from the mechanical stop.

2.

Slide the bracket along the rack in the opening direction until the

corresponding LED switches off, as in fig. 12. Then bring the

bracket forward by at least 2 cm and secure it to the rack with the

appropriate stud bolts.

3.

Manually place the leaf in the closed position leaving at least 2-3

cm from the mechanical stop.

4.

Slide the bracket along the rack in the closing direction until the

corresponding LED switches off. Then bring the bracket forward

by at least 2 cm and secure it to the rack with the appropriate

stud bolts.

Warning: the ideal distance of the bracket for inductive

limit switches is between 3 and 8 mm as indicated in fig. 13.

!

12

13

3÷8mm