EN

10

– English

Possible causes of malfunctions are listed below, which may occur during the

installation phase, or in the case of faults, possible remedies:

• The radio transmitter does not control the barrier and the transmitter led

does not illuminate:

Check that the transmitter batteries are not discharged

and replace if necessary.

• The radio transmitter does not control the barrier but the transmitter led illu-

minates: check that the transmitter is correctly memorised on the radio receiv-

er. Ensure correct emission of the radio signal of the transmitter with the follow-

ing empirical test: Press a key and place the led against the aerial of a standard

radio switched on and tuned to FM at the frequency of 108.5Mhz or as close to

this value as possible; a slight noise with a scratching pulse noise should be

heard.

• No manoeuvre is performed when a command is sent, and the OK led

does not flash:

check that the barrier is powered via the mains at 230 V. Also

check that the fuses F1 and F2 are not blown; in this case try to locate the

cause of the fault and then replace with a version with the same specifications;

see

fig. 42

.

• No manoeuvre is performed when a command is sent, and the flashing

light remains off:

check that the command is effectively received; if the sent

command reaches the SS input, the OK led emits a double flash to indicate that

the command is received.

• The manoeuvre does not start and the courtesy light flashes a few ti -

mes:

count the number of flashes and check with reference to the data in

Table

9

in Chapter 8.

• The manoeuvre is performed, but shortly afterwards the pole blocks and per-

forms a brief inversion: the selected force value may be too low to enable

movement of the pole. Check correct balancing of the pole; if necessary set a

higher force value.

WHAT TO DO IF…

(troubleshooting guide)

7

8.1 - Total deletion of control unit memory

It is possible to delete all memorised data on the control unit and reset it to the

original factory settings:

01.

Press and hold down “

▲

“ and “

▼

“ keys at the same time;

02.

Release the keys when all Led illuminate (after approx.3 seconds);

03.

When leds

L1

and

L2

start flashing, this means that the procedure is ter-

minated.

Important

– This procedure does not delete the parameter regarding the direc-

tion of motor rotation and the number of manoeuvres performed.

8.2 - Other functions

• “Always open” function

This function is a special feature of the control unit; it is associated with the

“Step Step” input and enables an “always open” command when the Step Step

command remains active for more than 3 seconds. This function is valid for any

setting of the Step Step input (see “SS Function” in

Table 7

).

For example, it can be used to connect a clock for programming permanent

opening of the barrier during a specific time band.

• “Move anyway” function

If one or more safety devices malfunctions or is out of service, this function

enables control of the barrier in “hold-to-run” mode (for details, see chapter

“operation manual”).

• “Maintenance notification” function

This function enables notification of when an automation maintenance check is

necessary. The “Maintenance notification” parameter can be set with a value on

8 different levels (see

Table 7

).

The levels refer to the number of manoeuvres performed. The maintenance

notification is signalled via the Flash flashing light or by the maintenance indica-

tor according to the type of setting. The signals emitted by the Flash flashing

light and the maintenance indicator are shown in

Table 9

.

• Check of number of manoeuvres performed

The function “Maintenance notification” enables the user to check the number

of manoeuvres performed as a percentage of the maximum set limit. Proceed

as shown in

Table 10

.

• Manoeuvre counter reset

The manoeuvres can be reset at the end of the automation maintenance

phase. To proceed, see

Table 11

.

FURTHER DETAILS

8

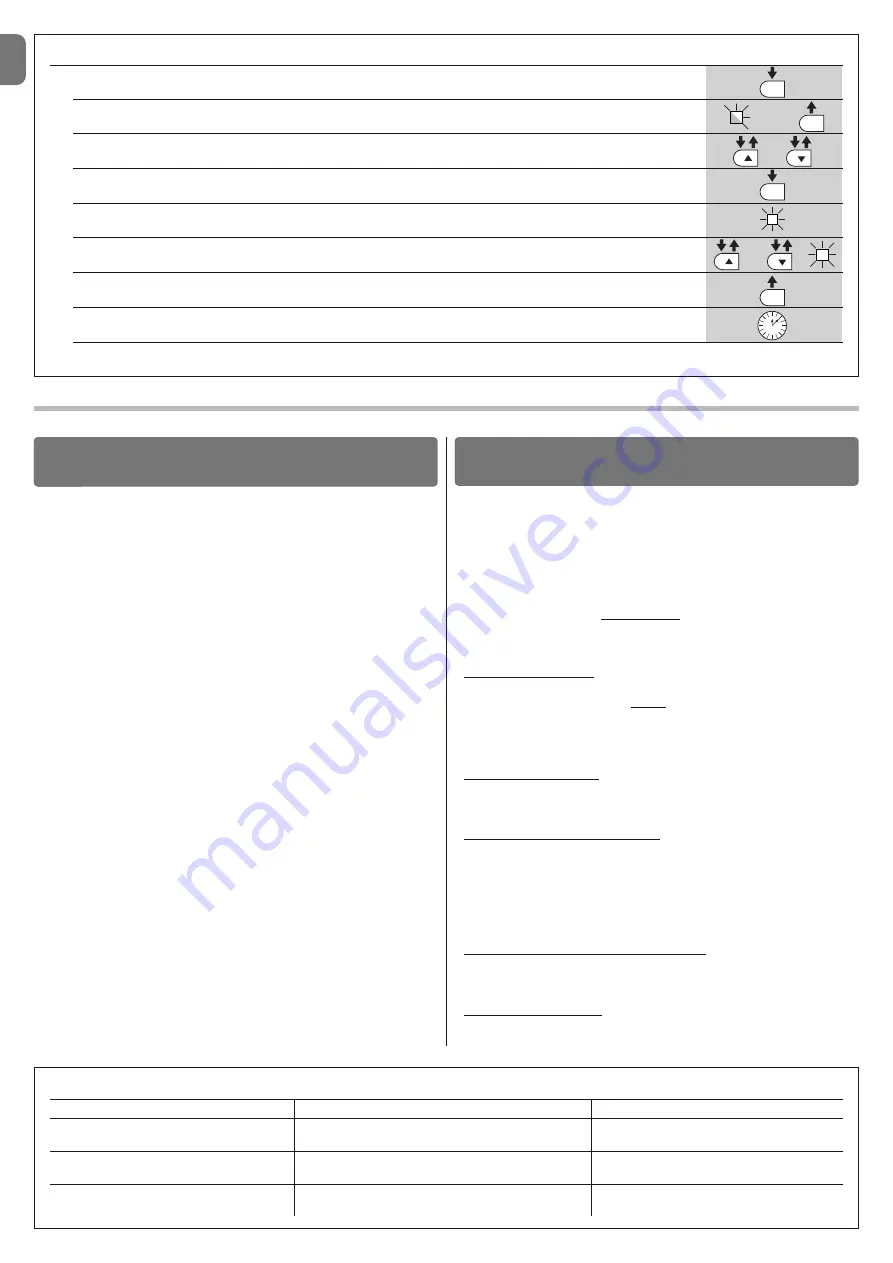

TABLE 9

Number of manoeuvres

Flash flashing light

Maintenance indicator

Below 80% of the limit

Normal (0.5 sec. lit - 0.5 sec. off)

Light on for 2 seconds at the start of the

opening manoeuvre.

Between 81% and 100% of the limit

Light on for 2 seconds at the start of the manoeuvre.

Flashing for entire duration of manoeuvre then

continuing as normal

Over 100% of the limit

At the start and end of the manoeuvre, remains lit

Always flashes

for 2 sec., then continues as normal.

TABLE 8

-

Programming procedure (second level functions)

01.

Press and hold down the “

Set

” key for approx. 3 seconds;

02.

Release the key when LED

L1

starts flashing;

03.

Press keys “

▲

” or “

▼

” to move from the flashing led to the led associated with the function to be modified;

04.

Press and hold the “

Set

” key through to completion of point 06;

05.

Wait approx. 3 seconds, until the LED representing the current level of the parameter to be modified illuminates;

06.

Press keys

▲

or

▼

to move the LED representing the value of the parameter;

07.

Release the “

Set

” key;

08.

Wait 10 seconds (maximum time) to exit the programming mode.

Note

– During this procedure, points 03 to 07 need to be repeated when programming other parameters during the phase itself.

SET

SET

SET

SET

L1

or

or

3 s

10 s

Summary of Contents for S-BAR

Page 78: ...I 2 1 A B C B 179 5 mm 330 mm 1146 mm 826 mm 4000 mm 3 b a d e f g h c ...

Page 79: ...II 5 A B C 1 2 4 ...

Page 80: ...III 9 10 90 6 A C B 7 8 B A ...

Page 81: ...IV 14 15 A B A B 11 A B 12 13 A B ...

Page 82: ...V 16 A B 17 18 ...

Page 83: ...VI 20 180 21 C C A B 1cm 1cm 19 A C B ...

Page 84: ...VII 22 23 26 L N 24 1 2 25 ...

Page 86: ...IX 30 A A B STOP 31 A B ...

Page 87: ...X 32 A B C D STOP 33 A B 34 ...

Page 88: ...XI 35 36 L8 37 A B 2 1 L7 L8 L8 A B C Op L5 L6 L7 L8 Stop Set Close F u s e 1 A T 38 ...

Page 89: ...XII 300 200 700 500 39 300 200 700 500 150 40 41 ...

Page 90: ...a c d e b XIII F2 F1 42 43 ...

Page 91: ...XIV 44 O pe n L1 L2 L3 L4 L5 L6 L7 L8 St op Se t Cl os e Fuse 1AT 45 f g ...

Page 93: ...IST SBARR01 4865_20 10 2011 www niceforyou com Nice SpA Oderzo TV Italia info niceforyou com ...