GB

3

To install the TCB sensitive edge, proceed as follows:

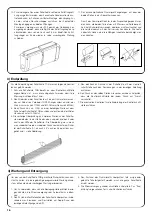

1. Cut the aluminium profile exactly to size and fix at the envisaged

point; to secure use 4 mm rivets or 3.5 countersunk head screws

taking care to countersink the aluminium profile sufficiently to

house the screw head. Secure at both ends of the profile and at

minimum 30 cm intervals throughout the length.

2. Place the TCB65 sensitive rubber profile on a flat surface, ensure

that it is not bent or twisted, and cut to size as required. The pro-

file length must be 25 mm shorter than length "L" of the finished

sensitive edge (space occupied by terminal caps). The cut must

be clean and burr-free and at perfect right angles to the length;

do not use a hacksaw, but the TCF scissors may be used if nec-

essary.

3. In relation to the outlet hole of the TCS250 connector wire (rear;

right or left), use a screwdriver to make a 3-5 mm hole in the

cable gland on the TCT65 terminal cap

4. Route the wire through the hole made above.

5. On the two ends of the sensitive rubber profile, insert the con-

nector TCS250 with wire on one end and the connector with

8200

Ω

terminal resistance on the other.

In this initial phase the 2 connectors should be inserted mid-way

and only pressed in fully later on.

Ensure that the four pins of the connector are inserted in

the vicinity of the copper wires inside the conductive strips.

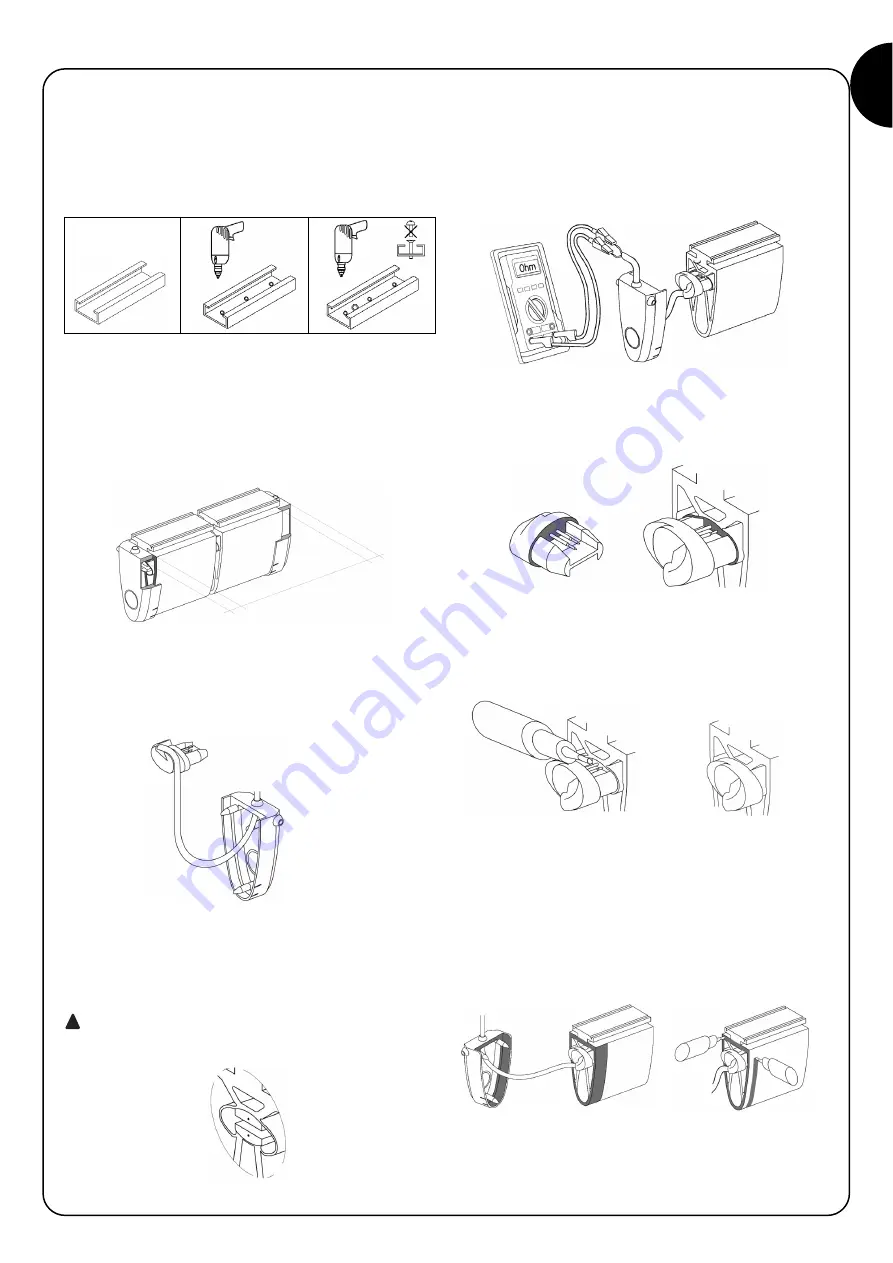

6. Using an Ohmmeter connected on the wire of the TCS250 con-

nector, measure the resistance value of the assembled edge; the

value must be 8200

Ω

± 500

Ω

, while on edge activation the val-

ue must be below 1000

Ω

. If these resistance values are not

detected, remove the connectors and repeat the insertion proce-

dure described in point 5.

7. Use the brush to apply the TCP activator on the surfaces of the

two connectors and the corresponding surfaces of the sensitive

rubber profile.

8. Apply the TCC adhesive in a circle on the connector only and

press it down immediately until the edge of the connector is

touching the border of the sensitive edge.

Repeat the same operations for the second connector.

9. Prepare the surfaces to be glued by spreading the TCP activator

on the sensitive rubber profile and the terminal caps.

Apply the TCC adhesive on the front and surrounding surfaces of

the sensitive rubber edge. Then place the terminal cap against

the sensitive rubber edge and immediately press the parts down

uniformly until the adhesive starts to act (approx. 20-30 seconds).

Repeat the same operations for the second terminal cap.

!

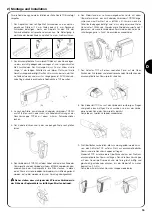

2) Assembly and installation

12,5

12,5

L