EN

4

– English

3.4 - Barrier fixture

3.4.1 - If the support surface already exists

[

] The fixing surface must be perfectly smooth and flat. If the surface is in

concrete, it must be at least 0 .15 m thick, and must be adequately reinforced

with steel cages . The concrete volume must be greater than 0 .2 m

3

(a thick-

ness of 0 .25 m corresponds to 0 .8 m

2

; in other words equal to a square base

of approx. 0.9 m per side).

Anchoring to the concrete can be by means of 4 expansion bolts, fitted with 12

MA screws, which resist to a traction load of at least 400 kg. If the fixing surface

is in another material, the consistency must be checked and ensure that the 4

anchoring points can resist a load of at least 1000 kg. For fixture, use 12 MA

screws .

Proceed as follows:

01.

Open the barrier cabinet (

Fig. 4

);

02.

Place the barrier on the fixing surface and trace the points where the slots

are to be fixed (

Fig. 9

);

03.

Move the barrier and drill the traced surface points; then insert 4 expansion

bolts, not supplied (

Fig. 10

);

04.

Position the barrier correctly and secure by means of the relative nuts and

washers not supplied (

Fig. 11 - A, B

) .

3.4.2 - If the support surface does not exist

01.

Dig the foundation pit to house the foundation plate, (optional accessory) .

For the pit dimensions, refer to the specifications at point [

] of paragraph

3 .4 .1 .

02.

Prepare ducting for connection cables;

03.

On the foundation plate, fix the 4 bolts, placing a nut on the upper side of

each and one on the lower side of the plate .

Caution

– The lower nut must

be tightened down to the threaded section;

04.

Now cast the concrete, and before it sets, embed the foundation plate,

which must be positioned flush with the surface, parallel to the pole and

perfectly level (

Fig. 12

) . Wait for the concrete to set completely; in general,

at least 2 weeks;

05.

Remove the 4 upper nuts of the bolts;

06.

Open the barrier cabinet (

Fig. 4

);

07.

Position the barrier correctly and secure by means of the relative nuts and

wa shers supplied with the foundation plate e moved in point 04 (

Fig. 13 -

A, B

) .

3.5 - Pole installation

3.5.1 - Pole support assembly

01.

Insert the two plugs in the relative seats on the output motor shaft (

Fig.

14 - phase A

and

B

);

02.

Position the support on the output motor shaft, placing it in the “vertical

pole” position and tighten the relative screws and washers fully down to

secure (

Fig. 15

- phase A

and

B

);

03.

Position the pole cover and partially secure by means of the 4 screws sup-

plied (

Fig. 16

- phase A

and

B

) .

3.5.2 - Pole assembly

01.

Assemble the two joints (

Fig.

17

); each joint is made up of 2 half-shells and

8 self-tapping screws;

02.

Insert a joint in the first aluminium profile (

Fig.

18

– use a rubber mallet to

insert fully);

03.

Insert the joint support brackets on both sides of the profile slots (

Fig.

19

- phase A, B, C, D

), ensuring correct alignment of the brackets (use a

mallet to facilitate insertion);

04.

Repeat the procedure from point 01, to insert the remaining aluminium

profiles;

05.

Position the holes of the joint support brackets so that they are aligned

with the holes on the profiles;

06.

Secure the brackets with screws supplied for each joint (

Fig.

20

) .

07.

Lightly grease the aluminium guide on both sides (

Fig. 21

) .

08.

Perform this operation on both ends of the pole: insert the first part of

impact protection rubber in the slot, through to the end of the pole; then

insert the joint for the impact protection rubber (

Fig.

22

) and repeat with all

parts;

09.

Position the pole plug (

Fig.

23

);

A) the upper impact protection must be inserted by at least 2 cm;

the lower impact protection must protrude by 1 cm;

B) Insert the pole plug;

C) Secure the plug using the relative screw;

D) Push the upper impact protection towards the plug, inserting it

by 1 cm into the plug;

10.

On the opposite end to that with the plug, insert the pole support plates

(

Fig.

24

);

11.

Insert the pole assembly in the pole support shell, pushing it up to the end

and then tighten the 4 previously inserted support screws fully down .

3.6 - Manually releasing and locking the gearmotor

The gearmotor can be released manually on both sides of the barrier

as shown in Fig. 25:

01.

Rotate the key cover;

02.

Insert the key supplied and turn through 180° both clockwise and anti-

clockwise;

03.

To lock the gearmotor, rotate the key through a further 180° in the same

direction as before .

3.7 - Mechanical stop adjustment

01.

Release the gear motor manually (see paragraph

3.6

);

02.

Manually move the pole through a complete Opening and Closing manoeu-

vre;

03.

Then adjust the mechanical stop screws (

Fig. 26

and

27

) to align the pole

vertically and horizontally;

04.

Tighten down the nuts .

3.8 - Pole balancing

The pole needs to be balanced to establish the best balance between two fac-

tors: the weight of the pole and any accessories and the counterposed force of

the balancing spring . The latter individually guarantees balancing of the pole; if

this rises or lowers, proceed as described below .

01.

Release the gear motor manually (see paragraph

3.6

);

02.

Manually move the pole to mid-travel (45°) and leave stationary . Then

ensure that the pole remains still in position . If the pole tends to lift, reduce

the tension of the spring, if the pole tends to drop, increase the tension of

the spring . To modify spring tension, see point 04;

03.

Repeat point 02 positioning the pole also at approx. 20° and approx. 70°.

If the pole remains still in position, this means that balancing is correct; a

slight off balance is admissible, but the pole must never move significantly.

The off-balance value is only acceptable when the force required to move

the pole (measured at right angles to the pole and at 1 m from the rotation

axis) on Opening, Closing and in all other positions, does not exceed half

the value of the maximum torque (for this product, approx. 5 kg at 1 m).

04.

- If the pole is not correctly balanced; to balance move the pole to the

maximum opening position.

- Detach the balancing spring from its seat (

Fig. 28

) and move its anchor-

ing point towards the centre, to reduce spring tension, or outwards to

increase spring tension;

05.

Lock the gear motor (see paragraph

3.6

) .

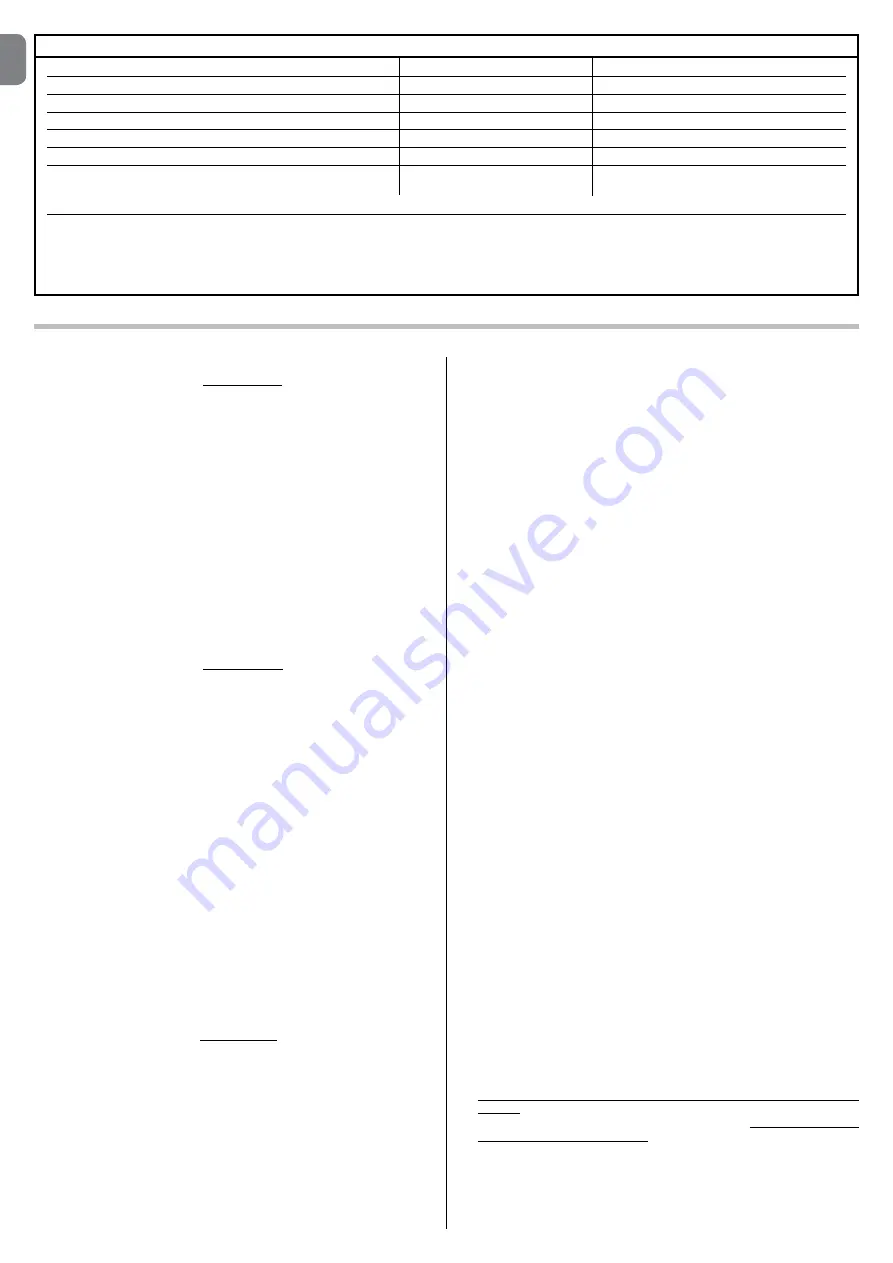

TABLE 3 - Technical specifications of electrical cables (Fig. 1)

Connection

Cable type

Maximum admissible length

A:

Mains POWER SUPPLY cable

cable 3 x 1,5 mm

2

30 m (

note 1

)

B:

Cable for BlueBus devices

cable 2 x 0,5 mm

2

30 m

C:

POLE LIGHTS

D:

KEY-OPERATED SELECTOR SWITCH cable

cables 4 x 0,25 mm

2

30 m (

note 2

)

E:

Built-in FLASHING LIGHT

OPTIONAL FLASHING LIGHT:

cable 2 x 0,5 mm

2

30 m

FLASHING LIGHT with aerial cable

RG58 shielded cable type

20 m (less than 5 m recommended)

IMPORTANT – To make the connection, programming of the FLASH output must be modified (see paragraph 6.2 - Table 7)

Note 1

– If the power cable is longer than 30 m, a cable with a larger cross-section is required (3 x 2.5 mm

2

) and safety earthing is necessary in the vicinity

of the automation .

Note 2

– If a MOMB transponder badge reader or MOTB digital keypad is used, a 2-wire cable is sufficient (2 x 0,5 mm

2

) .

CAUTION! – The cables used must be suited to the installation environment.

Summary of Contents for X-Bar

Page 2: ......

Page 3: ...I 1 A B D C D B 3 2 179 5 mm 300 mm 1146 mm 826 mm 3000 mm b a l d e c i g f h...

Page 4: ...II 5 A B C 4...

Page 5: ...III 9 10 90 6 A C B 7 8 B A...

Page 6: ...IV 14 A B 15 A B 11 A B 12 13 A B...

Page 7: ...V 18 17 16 A B...

Page 8: ...VI 20 21 OK O O 19 A B C D...

Page 9: ...VII 22 A 2cm 1cm 23 A B C D...

Page 10: ...VIII 24 26 27 180 25 C C A B...

Page 12: ...X Op en St op Se t Cl os e Fuse 1AT L1 L2 L3 L4 L5 L6 L7 L8 34 35 36 A A B...

Page 13: ...XI STOP 37 A B 38 A B C D...