6

LoadRunner™ Series Installation & Service Manual

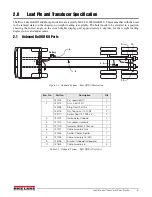

3.0

Roll Off Load Pin Installation

Load pins supplied are custom sized to fit the specific hinge and ram brackets of the vehicle. The

LoadRunner

Roll

Off system is compatible with Galbreath, Accurate and Ruddco. Installation requires removal of existing pins, and

replacements of these pins with Rice Lake load pins and collars.

Important

All load pin installations require lubrication facilities. Normally lubrication is provided through the central

pivot area. OEM Roll Off pivots typically have existing lubrication fittings included in their pivots. Rice

Lake pivots are furnished with drilled and tapped holes for the insertion of a standard lube zirk which

must be supplied and installed by the system installer.

Load

Pins

Inclinometer

Y Cable

Battery

Transducer

Indicator

Power Cable

Homerun Cable

Figure 3-1. LoadRunner System Layout

3.1

Installing the Load Pins

1. Remove the rear fenders from the truck, if required, to gain free and clear access to the pivots.

2. Use jacks or a forklift to support the rear of the hoist chassis and maintain its position/alignment while the

pivot pins are being replaced.

3. Remove the bolt and washer from the outer collar on the pivot.

Note

Removing pivot pins on some vehicles may be difficult if rust is present or if the hoist chassis pivot and the truck

chassis supports are out of alignment. If rust is an issue, use a penetrating lubricant and appropriate tools for

tapping the pivot pin out. Use a pry bar as a lever to assist with any misalignment problems to remove the

existing pivot pins.

4. Push the pivot pins into the frame and out the other side, removing the inside collar as well.

5. Remove the outer collar if still attached to the frame.

6. Using a power grinder or a wire brush, clean around the hole where the pivot was located, both sides of the

frame.

7. Grind the frame smooth to ensure a clean weld at load cell installation.

8. Remove any debris that is inside and around the holes of the chassis supports and the pivots.

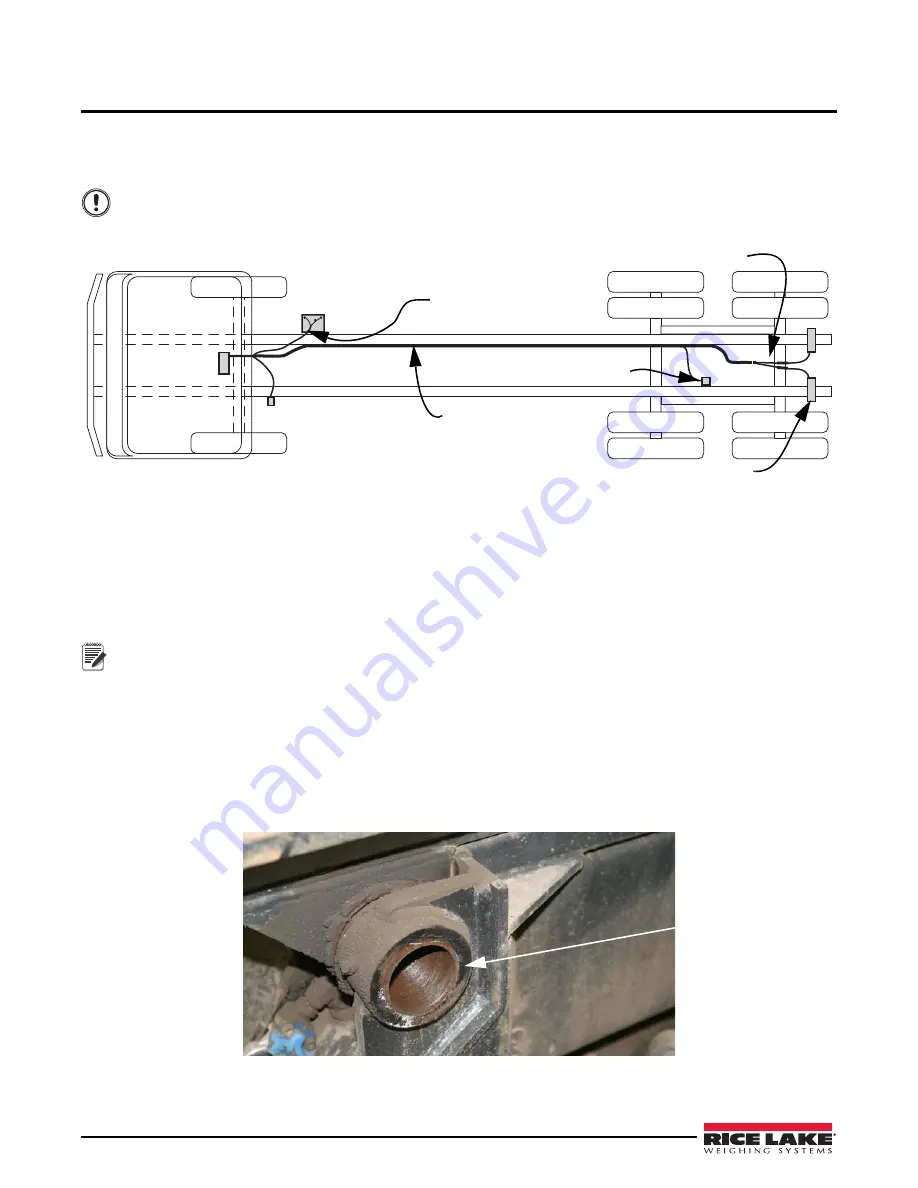

Remove existing pin and

prepare surface for load

pin installation

Figure 3-2. Remove Existing Pin