16

LoadRunner™ Series Installation & Service Manual

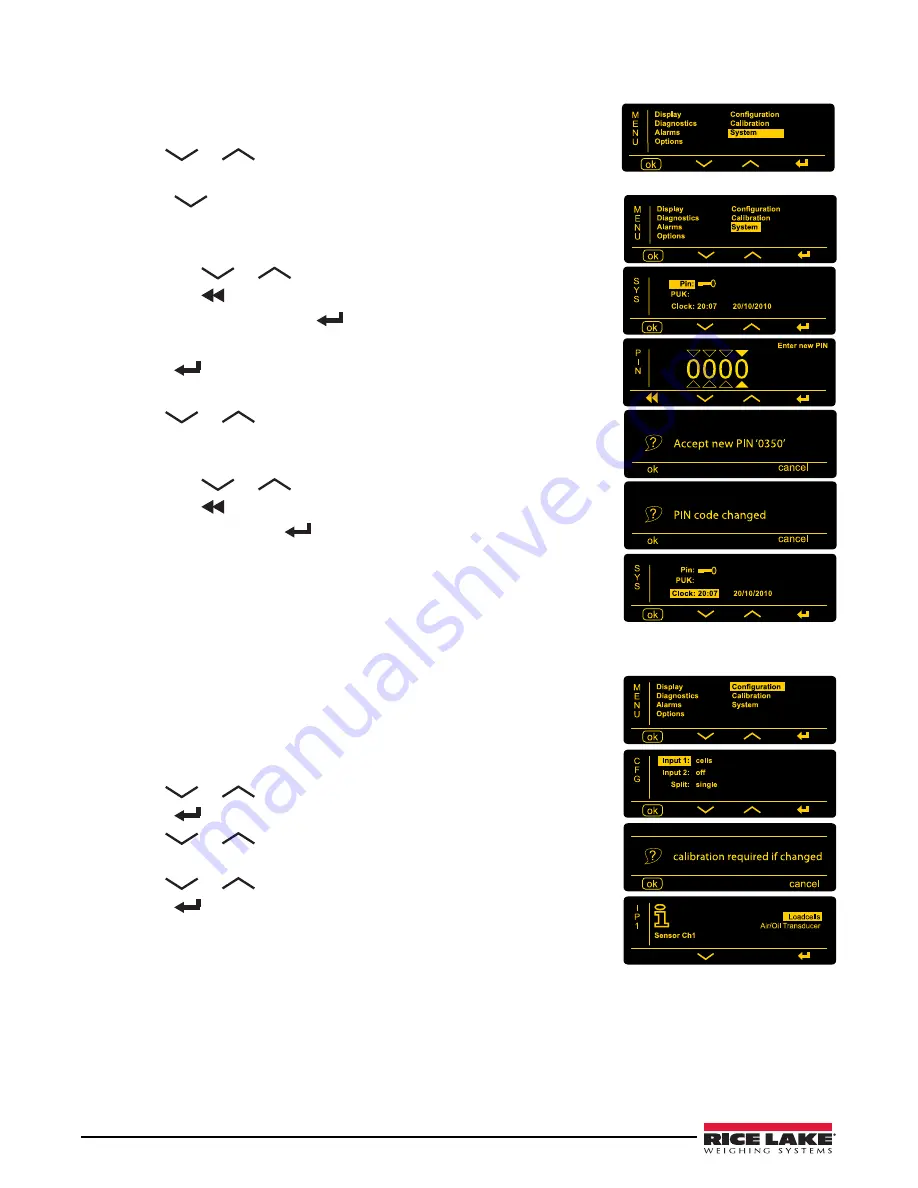

4.2.1

Initial Password Entry and Clock Setup

1. Press the power button to power on the indicator.

2. Press the

Circle

key to enter the menu screen.

3. Use

or

to scroll to

System

.

4. Press

(OK).

5. Press

to select

Pin

.

6. Press

(OK)

to display PIN input screen.

7. Enter Password or Pin code,

0 3 5 0,

using the following:

•

Press

or

to number 0-9.

•

Press

to move cursor left.

8. When PIN is correct, press

to enter code.

9. Press

(OK)

to accept PIN.

10. Press

to back up to MENU.

11. To Set PIN, select PIN, press

(OK)

12. Use

or

to scroll to

Clock

.

13. Press

(OK).

14. Select the

edit

key to modify time (military) and date (international)

•

Press

or

to number 0-9.

•

Press

to move cursor left.

15. When complete, press

three times to exit and return to system setup

menu

4.2.2

Configuration of Input Channels

1. Scroll to

Configuration

.

2. Press

(OK)

.

3. Press

(OK)

with

Input 1

selected

.

4. Press

(OK)

again to configure the channel.

5. Use

or

to scroll to

Air/Oil Transducer

.

6. Press

.

7. Use

or

to scroll to

Input 2

.

8. Press

(OK)

again to configure the channel.

9. Use

or

to scroll to load cells.

10. Press

to return to the system setup menu

.