9

Care and Maintenance

Cleaning

$

Unplug the weighing instrument from the AC power before cleaning. Remove dust from the

weighing platform regularly (see EC type-examination certificate)

$

If the weighing instrument is in a dry room, use a damp cloth to wipe down the weighing

platform. You can use common household cleaning agents. Follow the manufacturer’s

instructions for the cleaning agent.

$

The leveling feet are covered with rubber buffers. In hazardous areas/locations, these must be

cleaned using only a damp cloth. This prevents build-up of static electricity.

!

Never use concentrated acids, bases, solvents or pure alcohol to clean the weighing platform.

$

To clean the weighing platform in a wet area, wash it down using a gentle stream of water

(60°C max.) sprayed over the top of the load plate.

!

Do not use high-pressure cleaning equipment to clean the weighing platform.

> If the water that you use to clean the weighing platform is too hot or too cold, the difference in

temperature between the water and the weighing platform can cause condensation within the

weighing platform. This condensation may cause the weighing platform to malfunction.

$

If the scale is installed in a pit, make sure that no debris builds up in the crevices between the

pit and the platform, to prevent weighing errors.

$

Regularly remove debris from the bottom of the pit.

Cleaning the Inside of the Weighing Platform

$

To clean the inside of the weighing platform, remove the load plate. Be especially careful when

removing the load plate from scales of 1000 x 1000 mm or larger.

!

Please follow the safety instructions.

$

Use compressed air to blow debris out of the inside of the scale or flush out using a gentle

stream of water (60°C max.). Make sure that no debris builds up in the gap between the load

receptor and the fastening plate, to avoid compromising the overload protection.

Corrosive Environment

$

Remove all traces of corrosive substances from the weighing platform on a regular basis.

Instructions for Recycling the Packaging

If you no longer need the packaging after successful installation of the equipment, you should

return it for recycling, as it is a valuable source of secondary raw material. Sartorius products

are packaged to ensure safe shipment using environmentally friendly materials. For information

on recycling options, including recycling of old weighing equipment, contact your municipal

waste disposal center or local recycling depot. Make sure you remove the batteries before

disposing of the equipment. Rechargeable batteries are toxic waste and as such may not be

disposed of with normal household waste. Contact your municipal waste disposal center or local

recycling depot for details on the proper disposal of batteries.

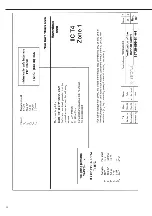

Model-specific Information: Serial Number Coding

The month and year of manufacture are encoded in the serial number as follows:

Y M M x x x x x

Y= Year:

1

2000–2006

2

2007–2013

3

2014–2020

4

2021–2027

5

2028–2034

6

2035–2041

7

2042–2048

8

2049-2055

9

2056-2062

The first digit represents a 7-year period as indicated in the table above. The next 2 digits

represent the month. The months are numbered consecutively, starting with 13, over the entire

7-year period. Thus the number representing the month also indicates the specific year of

manufacture.

2000

13-24

2001

25-26

...

Example:

113xxxxx -> January 2000

The individual devices are numbered consecutively in the last 5 digits, starting from 00000 again

at the beginning of each month.

Summary of Contents for Sartorius Combics CAPXS Series

Page 13: ...12 EC Type Approval Certificate...

Page 14: ...13...

Page 15: ...14...

Page 16: ...15...

Page 17: ...15...

Page 18: ...16...

Page 19: ...17...

Page 20: ...18...

Page 21: ...19...

Page 22: ...20...

Page 23: ...21...

Page 24: ...22...

Page 25: ...23...

Page 26: ...24...

Page 27: ...25...

Page 28: ...26...

Page 29: ...27...

Page 30: ...28...

Page 31: ...29...

Page 32: ...30...

Page 33: ...31...