4

Installation Instructions

§

Prepare a suitable place of installation for the weighing platform. The place of

installation should be dry, level and even. The allowable operating temperature range

is -10°C to +40° (14°F to 104°F). The permissible load that can be carried by the

chosen working surface must be sufficient for both the weighing platform and any

load placed on the platform.

If you need to use the weighing platform in areas exposed to heavy traffic (e.g., forklift

trucks), you should install a protective frame, consisting of angular braces, around the

weighing platform.

Do not expose the weighing platform unnecessarily to extreme temperatures, moisture,

shocks, or vibration that could result in damage.

§

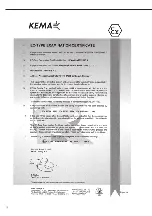

The air bubble must be centered within the circle on the level indicator.

§

Level the weighing platform using the leveling feet as described below:

§

Check to ensure that all leveling feet rest securely on the work surface.

> Each of the leveling feet must support an equal load.

§

Loosen the lock nuts on the leveling feet using a 19-mm open-end wrench (spanner).

> Adjusting the leveling feet:

To raise the weighing platform, extend the leveling feet (turn clockwise).

To lower the weighing platform, retract the leveling feet (turn counterclockwise .

§

After leveling the weighing platform, retighten the lock nuts securely as described

below:

Low-capacity platforms (1 load cell): tighten the lockouts against the platform frame;

high-capacity platforms (4 load cells): tighten the lock nuts against the platform feet.

§

If the weighing platform is in a hazardous area/location, it must be grounded (i.e., an

equipotential bonding conductor must be connected). This connection should be made

by a trained technician.

All Combics weighing platforms are equipped with a connector for the grounding

conductor.

This is located either below the load pan, on the junction box, or on the lower frame of

the weighing platform. The position is marked in each case by the symbol shown here,

indicating the grounding (earthing) connection.

The grounding conductor is connected to a threaded bolt or terminal screw, or a bore

hole is provided. If a bore hole is provided, use a stainless steel screw and nut to

connect the grounding conductor. Use of a tooth lock washer is recommended, to

prevent the screw from coming loose. The wire used for the grounding conductor

should have a cross-sectional diameter of at least 4 mm

2

, with a suitable ring lug

attached.

Connect all equipment, including peripheral devices, to the equipotential bonding

conductor

Summary of Contents for Sartorius Combics CAPXS Series

Page 13: ...12 EC Type Approval Certificate...

Page 14: ...13...

Page 15: ...14...

Page 16: ...15...

Page 17: ...15...

Page 18: ...16...

Page 19: ...17...

Page 20: ...18...

Page 21: ...19...

Page 22: ...20...

Page 23: ...21...

Page 24: ...22...

Page 25: ...23...

Page 26: ...24...

Page 27: ...25...

Page 28: ...26...

Page 29: ...27...

Page 30: ...28...

Page 31: ...29...

Page 32: ...30...

Page 33: ...31...