Rev. 1 - 05/10/2021

OPERATING MANUAL

OPERATING MANUAL

EN

EN

32/56

10. OPERATING MODES AND SETTING OPTIONS

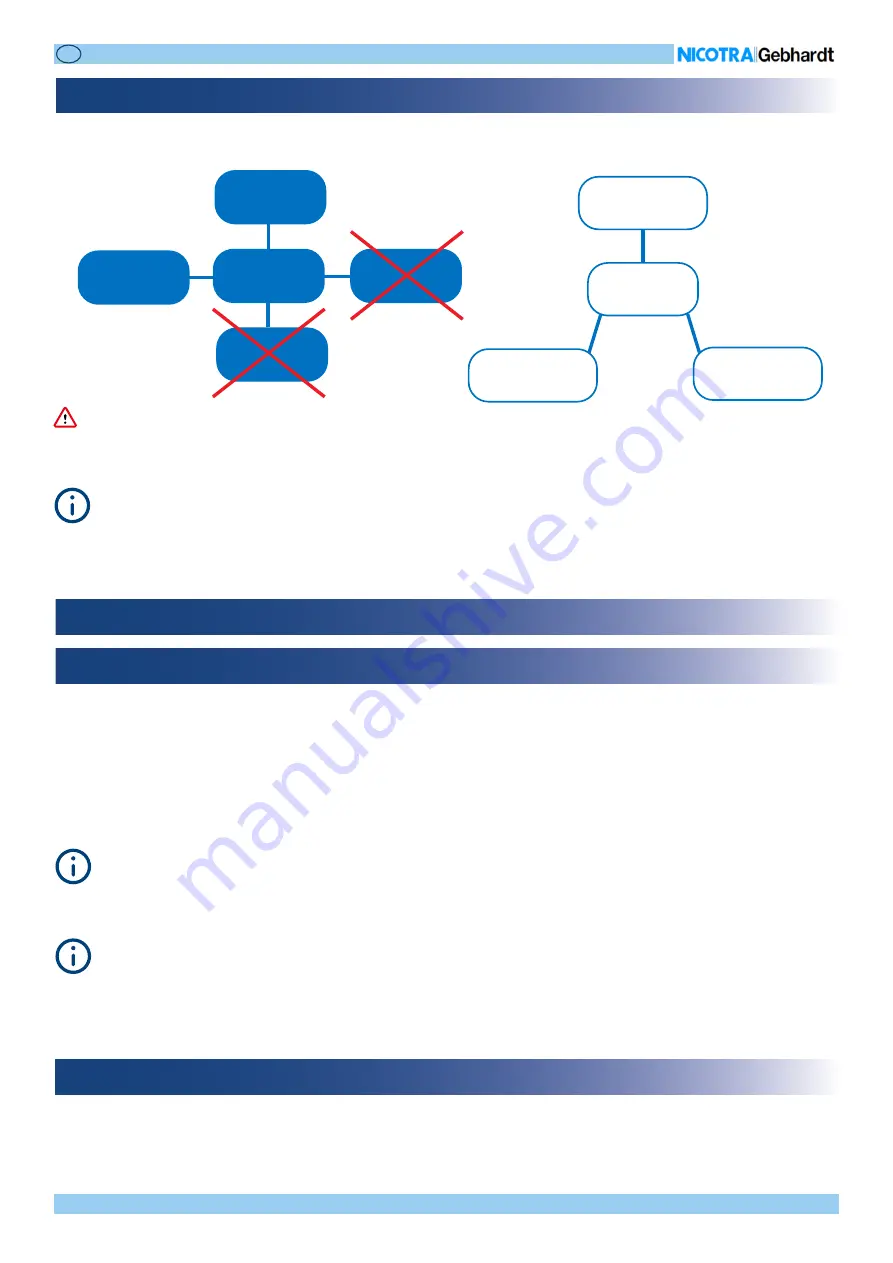

Depending on the fan model, there are 4 possible

Operating Modes and for each mode 3 possible Setting

Options.

The operating modes and the setting options can be chosen by modifying the INPUT TYPE

Holding Register 34.

10.1 Speed control

(INPUT TYPE = 1 Default factory setting)

Through this setting the fan speed is proportional to the analog voltage input. The fan speed is limited by the

Safe Operating Area, therefore, depending on the fan working point, the fan could be no more able to increase

the speed coherently to the set voltage value.

To avoid the loss of signal dynamic, a speed limit rescaling is necessary by modifying the value of the Max

Speed

Holding Register 2. It is also possible to rescale the min Speed by modifying the Holding Register 1.

The analog signal can be read from the

Input Register 14.

For more details refer to the ANNEX -> Analog Signal Considerations.

The MAX and min speed default values are in function of the fan sizes.

10.1.1 Analog speed control

(INPUT TYPE = 0)

Through this setting the fan runs at the speed defined by modifying the

Holding Register 66.

The setting is maintained meanwhile the fan is powered on and it is lost when the fan is powered off.

10.1.2 Modbus temporary speed control

The relationship between control voltage and fan speed is described in paragraph 10.1.4 and, with more detail,

in chapter 1 of the Technical Annex to this manual.

The minimum speed holding register cannot be modified for 1.05kW 1-Ph and 2.1kW 1-Ph.

Speed Control

OPERATING

MODES

PID Closed

Control

Loop

Asynchro-

nous Emulation

Constant

Airflow

Sensorless

SETTING

OPTIONS

Modbus Control

(Temporary setting)

Fixed Modbus

(Permanent

setting)

Analog Signal

Control

The operating mode “Constant Airflow” is not available for RDPs. Setting the fan in one of the three Constant

Airflow modes could make it turn in an unknown and/or uncontrollable manner.

The algorithm related to the operating mode "Asynchronous Emulation" does not produce significant

differences on RDPs in comparison to the operating mode "Speed control". Therefore, its use is not

recommended.

WARNING

WARNING