XR67

1

8 9 0 1 E . P L E A S A N T VA L L E Y R O A D • I N D E P E N D E N C E , O H I O 4 4 1 3 1 - 5 5 0 8

T E L E P H O N E : ( 1 ) 2 1 6 - 6 4 2 - 1 2 3 0 • FA X : ( 1 ) 2 1 6 - 6 4 2 - 6 0 3 7

E - M A I L : t a c h s @ n i d e c - a v t r o n . c o m • W E B : w w w. a v t r o n e n c o d e r s . c o m

Nidec-Avtron Makes the Most Reliable Encoders in the World

Encoder Instructions

MODEL

XR67 SMARTSafe

™

6 3/4” C-FACE MOUNT

MODULAR FOR HAZARDOUS

APPLICATIONS

DESCRIPTION

The Avtron XR67, SMARTSafe™ is a modular, two piece incremental

encoder for hazardous atmosphere applications (also known as a

tachometer or rotary pulse generator). It provides a two phase, A Quad

B frequency (pulse) output, with complements. The XR67 mounts on a

6.75” Face.

CAUTION

The XR67 is designed for use in hazardous applications

which require protection from gas or dust ignition for

safe operation. Proper selection, wiring and installation

procedures are essential to ensuring safe conditions.

Because the XR67 is modular, there are no bearings or couplings

required. This, combined with the latest magneto resistive (MR)

sensor technology, allows the XR67 to provide superior mechanical

performance and increased reliability.

An Avtron XR67 can be configured with one or two independent

outputs. Each output has six signals: (A, B) 90° out of phase, with

complements (A–, B–). A marker pulse with complement (Z, Z–) is also

provided.

Output resolution on the XR67 is determined by the sensor only.

Unlike older models, any PPRs can be mixed and matched. Selection

of the rotor is based only on the shaft mounting requirements (and not

PPR).

ADAPTIVE ELECTRONICS

A perfect duty cycle consists of a waveform whose “high” and “low”

conditions are of the same duration (50%/50%). It is possible over time

for the duty cycle and edge separation to change due to component

drift, temperature changes, or mechanical wear. The Adaptive

Electronics extend the life of the XR67 by constantly monitoring and

correcting duty cycle and edge separation over time.

INSTALLATION

WARNING

Installation should be performed only by qualified

personnel. Safety precautions must be taken to ensure

machinery cannot rotate and all sources of power are

removed during installation.

Refer to the following attached installation drawings for

installation information appropriate for specific hazardous

locations:

D52352: ATEX / IECEx Zone 1, 21

D52353: ATEX / IECEx Zone 2, 22

D52354: US and Canada Class I Division 1 Encoder

D52355: US and Canada Class I Division 2

NOTE:

The equipment is intended for a fixed installation and

should be mounted so as to avoid electrostatic charging.

The XR67 is not considered as a safety device and is not

suitable for connection into a safety system.

The XR67 construction materials contain no more than 7.5% in total

by mass of magnesium, titanium and zirconium. These materials are

not considered as able to trigger an explosion in normal operating

modes. These materials are not known to react with any explosive

atmospheres to which the XR67 may be subject. It is however the

responsibility of the end user to ensure that the XR67 is selected

correctly for the potentially explosive atmosphere in which the

equipment is to be put into service.

The XR67 installation is similar to AV67. Installation and removal

videos for the AV56/67/85/115 are available on Avtron’s web site.

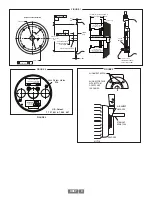

Refer to the back page of these instructions for outline and mounting

dimensions. The motor must comply with 1998 NEMA MG 1, section 4,

for tolerances on diameters and runout for shafts and accessory faces.

Axial float or endplay plus rotor location toleration must be less than

±0.050”.

In preparation for installing the Model XR67 encoder, it is first

necessary to clean both the accessory motor shaft and the mounting

face. These surfaces must be inspected and any paint, burrs, or other

surface imperfections removed.

Installation procedures should be performed only by qualified

personnel. Safety precautions must be taken to ensure machinery

cannot rotate and all sources of power are removed during

installation.

ROTOR INSTALLATION

The motor shaft must project at least 0.88” from the motor recessed

pilot. For set screw rotors only: Apply anti-seize compound to the motor

shaft. For all rotors: Slide the rotor onto the shaft with the marking

“Motor side” facing in, (toward the motor face). The rotor centerline

must match the sensor centerline. To accomplish this, use the rotor

locating gauge (A28504) and slide the rotor onto the shaft until it is in

the proper position as shown in Figure 1. If a guage is not available,

use the stator housing alignment grooves as shown in Figure 3.

STANDARD CAM SCREW ROTOR INSTALLATION

Turn the cam screws of the rotor in the directions shown on the rotor to

engage the cams. Tighten to 50-60 in-lb [5.6 - 6.8 N-m] (See Figure 2)

using the 3mm hex wrench. Total cam screw rotation will be less than

one turn.

CAUTION

Do not adjust the cam screws before motor shaft

mounting; bottoming out the screws, or backing them

out excessively, can lead to insufficient shaft holding

force. Thread locker is preapplied on the cam screws.

LARGE BORE SET SCREW ROTOR INSTALLATION

Apply thread lock er to the rotor set screw holes, preferably from the

inside of the rotor bore before mounting. Tighten the rotor set screws

to 15 in-lb [2 N-m] using the 2mm T-handle hex wrench.

CAUTION

Use only a T-handle or torque hex wrench to tighten set

screws; using a right angle wrench will not provide

enough holding force, and the rotor may slip.

Summary of Contents for Avtron SMARTSafe XR67

Page 13: ...XR67 13...

Page 14: ...XR67 14...