Push the pedal all the way back

to stop the wheelhead.

Turn the power switch OFF.

Maintainance

Turn the power switch off and unplug

the power cable for cleaning, testing or

adjustment. (It is recomended to do the

same if the wheel will not be in use for

a long period.)

DO NOT POUR WATER ON

THE WHEEL TO CLEAN IT.

Wipe the wheel down with a damp

sponge or cloth. (Splash pan can be sat-

urated if it is removed from the wheel.)

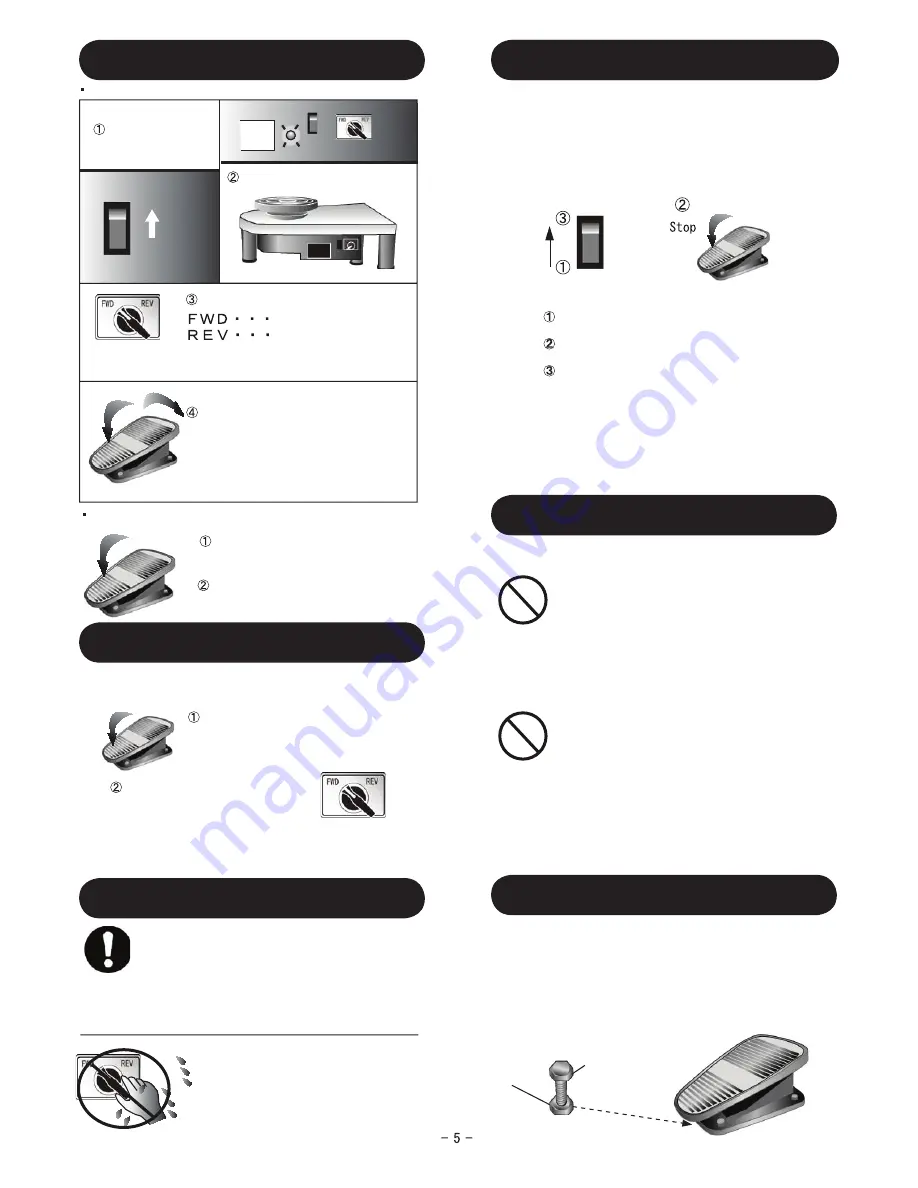

Operation Starting and Stopping

Turn the power

switch ON

Set the wheelhead direction.

Clock wise

Counter clock wise

Push the pedal forward from the

stop position to increase speed.

Push backward to reduce speed.

Operation Power Switch

The power switch has two functions. One is to turn the

wheel on and off. The other is as a reset function. This

wheel has a safety feature for over-load . In order to re-

set, operator must switch off and on again. (Don’t forget

to push the foot pedal to the off position before turning

the switch back on).

Operation Switching Directions

Stop the wheelhead by pushing the

foot pedal all the way back to the stop

position.

Turn the selector switch for

the opposite direction.

Never change the wheelhead direction while the wheelhead

is moving.

The power indicator lights up.

stop

Start

Stop

Operation Warning

Push the foot pedal in the stop

position before turning the power

switch off.

Do not operate any switches

with wet hand.

The wheelhead will not move if the pedal

was not all way back when last powered off.

stop

faster

Stop

Foot Pedal Adjustment

If the wheelhead does not react accurately

to the proper “stop” and “full speed”

postions, adjust the stopper bolt on the foot

pedal using the wrench provided. Adjust

the stopper bolt accordingly to create a new

“stop” and “full- speed” position.

Lock nut

stopper bolt

Mainteinance

Switch the ON/OFF breaker switch to

the stop position (refer to diagram).

Return the foot pedal to the stop

position (refer to diagram).

Turn the power switch back on.

Note: If you do not return the foot pedal to the stop position

the direction will not change even if the FWD/REV switch

is changed.

Note: If the pedal is not returned to the stop

position before the power switch is turned

on, the wheelhead will not turn; your wheel

will not respond.

Summary of Contents for Shimpo VL-Whisper

Page 9: ...Memo 8...