LLE14BRDA001A/E

7 - 58

4. Open the processing chamber door.

5. Dress the wheel.

<Roughing wheel for glass lenses and finishing wheel>

1) Press

. The wheel rotates and cooling water runs.

2) Wet the dressing stick well with running water.

Finishing wheel => Use the dressing stick for finishing wheel.

Roughing wheel for glass lenses => Use the dressing stick for roughing wheel.

3) Press

to stop the cooling water.

4) Apply the dressing stick to the rotating wheel with slightly increased pressure. Continue

applying the stick to the wheel for approx. 5 seconds.

5) Release the dressing stick from the wheel.

6) Press

. Start the cooling water to wash the wheel surface away.

7) Repeat Steps 3 to 6 two or three times.

8) Press

. The wheel and water come to a stop.

<Polishing wheel and flat polishing wheel>

* Maintain the polishing wheel and flat polishing wheel with the compound kit.

1) Press

. The wheel rotates and the

cooling water runs.

2) Press

to stop the cooling water.

3) Press

to stop the water of the water

curtain.

4) Attach a pad to the specified stick. Attach

the blue surface of the pad to the rough

surface of the stick.

5) Thoroughly apply the supplied compound

to only one side of the pad.

Pad

Specified stick

Compound

㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖

㧖ޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓ㧖

㧖ޓޓޓޓޓޓޓޓޓޓޓޓ㨃㨔㨑㨑㨘ޓ㨐㨞㨑㨟㨟㨕㨚㨓ޓޓޓޓޓޓޓޓޓޓ㧖

㧖ޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓ㧖

㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖

ޓޓޓޓޓޓޓ㧼㨞㨑㨟㨟ޓ㨍ޓ㨒㨛㨘㨘㨛㨣㨕㨚㨓ޓ㧿㨃ޓޓޓޓޓޓ

ޓ

ޓޓޓޓޓޓޓޓޓޓޓ㨣㨔㨑㨚ޓ㨚㨛㨠ޓ㨏㨔㨡㨏㨗㨕㨚㨓㧚ޓ

ޓ

ޓޓޓޓ㧿㨀㧭㧾㨀 㧦ޓ㧰㨞㨑㨟㨟㨣㨍㨠㨑㨞ޓ㨛㨚㧘

ޓ㨛㨒㨒ޓ

ޓ

ޓޓޓޓ㧿

㧦ޓ㧿㨍㨒㨑㨠㨥ޓ㧮㨑㨢㨑㨘ޓ㨃㨔㨑㨑㨘ޓ

ޓ

ޓޓޓޓ㧿㨀㧻㧼

㧦ޓ㧼㧭㨁㧿㧱ޓ

ޓ

ޓޓޓޓ㧱㧺㨀㧱㧾 㧦ޓ㧱㨄㧵㨀ޓ

ޓ

ޓ

Summary of Contents for Le 1000

Page 1: ...PATTERNLESS EDGER Model SERVICE MANUAL June 2008 Pages in total 152 LLE14BRDA001A E...

Page 8: ...This page is intentionally left blank LLE14BRDA001A E 1 2...

Page 10: ...This page is intentionally left blank LLE14BRDA001A E 2 2...

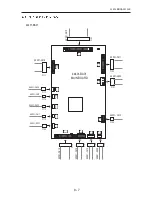

Page 19: ...LLE14BRDA001A E 3 9 3 3 Model Configuration...

Page 22: ...LLE14BRDA001A E 3 12 5 4 01 000000 9CVGT RTGUUWTG CZ M2C EU area only...

Page 28: ...LLE14BRDA001A 3 18...

Page 34: ...LLE14BRDA001A E This page is intentionally left blank...

Page 91: ...LLE14BRDA001A E 7 27 7 4 2 Parameter list of BL motor 40340 E066 E067 inverter User parameter...

Page 92: ...LLE14BRDA001A E 7 28 User parameter...

Page 93: ...LLE14BRDA001A E 7 29 System parameter...

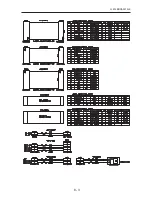

Page 126: ...LLE14BRDA001A E 8 2 8 2 Connector Cable...

Page 127: ...LLE14BRDA001A E 8 3...

Page 128: ...LLE14BRDA001A E 8 4...

Page 129: ...LLE14BRDA001A E 8 5...

Page 130: ...LLE14BRDA001A E 8 6...

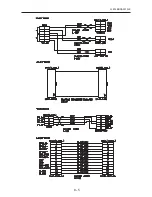

Page 131: ...LLE14BRDA001A E 8 7 44401 BA01 2 2 2 2 2 2 2 2 2 2 2 44401 BA01 MAIN BOARD 2 2 2...

Page 134: ...LLE14BRDA001A E 8 10 8 5 Grease MSDS 8 5 1 NIPPECO LLP...

Page 135: ...LLE14BRDA001A E 8 11...

Page 140: ...LLE14BRDA001A E 8 16 8 5 4 NBU15...

Page 141: ...LLE14BRDA001A E 8 17...

Page 142: ...LLE14BRDA001A E 8 18...

Page 143: ...LLE14BRDA001A E 8 19...

Page 144: ...LLE14BRDA001A E 8 20...

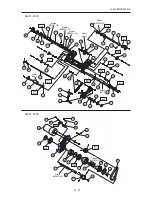

Page 145: ...LLE14BRDA001A E 8 21 8 6 Troubles and Measures...

Page 146: ...LLE14BRDA001A E 8 22...

Page 147: ...LLE14BRDA001A E 8 23...

Page 148: ...LLE14BRDA001A E 8 24...

Page 149: ...LLE14BRDA001A E 8 25...

Page 152: ...LLE14BRDA001A E 8 28 This page is intentionally left blank...