8. MAINTENANCE

Note: Only the specialized technician can do the maintenance. Before any maintenance is

performed, disconnect the power and keep the plug within the sight of the maintenance

personnel. and shut off compressed air, push the air valve switch to “Off” position and depress

pedal 16 for 3 or 4 times to bleed the residual compressed air in the machine.

To keep the tire change in good condition and to prolong the work life, it is necessary to do

regular maintenance according to the instructions on the user’s manual. Otherwise, the normal

operation and reliability of the machine will be affected, or personal injury would be caused.

•

Keep the machine and working area clean and prevent dust or foreign matter from entering

the moving parts.

•

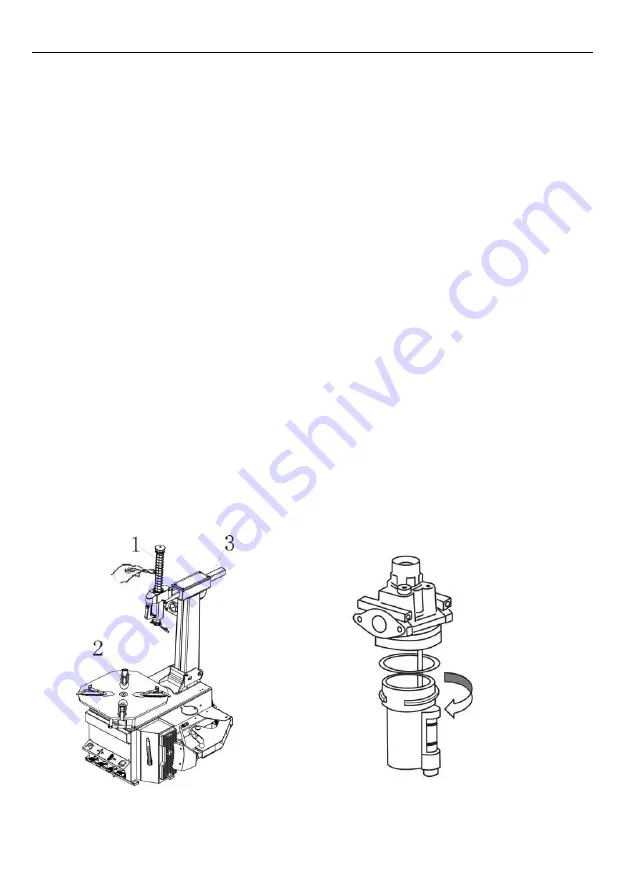

Keep the quadrate column and the moving parts clean and lubricate (clean with diesel as in

Fig.29-1 & 2 & 3 )

•

Keep the swing arm clean and lubricate it periodically so that it can moveexpectably.

•

Weekly lubricate the faying surface between moving parts and rubbing surface with lithium

lubricant.

•

Check the oil level in the sprayer regularly. If the oil level does not reach the second line, fill

hydraulic oil L-HM46 (Fig. 30).

•

Clear away the condensed material in the water separator around the sprayerregularly.

•

Regularly check and adjust the tension of the belt.

•

Check all connecting parts and bolts regularly and tighten them ifnecessary.

•

Check and adjust locker handle periodically, to make sure after locking, mount head and

rim keep 2-3m distance.

Fig.29

Fig.30

Summary of Contents for CT2880

Page 24: ...13 EXPLODED DRAWINGS Column assembly Fig 31...

Page 25: ...Turntable assembly Fig 32...

Page 26: ...Gearbox motor assembly Fig 33...

Page 27: ...Body assembly Fig 34...

Page 28: ...Pedal Assembly Fig 35...

Page 29: ...Bead Breaker Cylinder Breaker Arm Assembly Fig 36...

Page 30: ...Quick inflating system Optional Fig 37 Assemble...