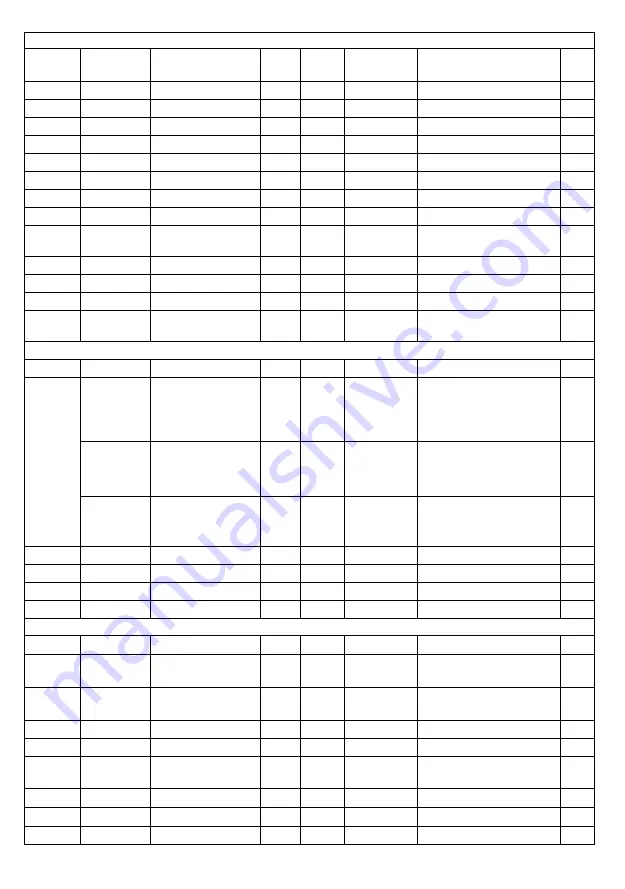

2064938 Parts of Gearbox Assembly (Fig. 33)

306

2064938 Complete

gearbox

1

320

6000148

Screw

M8

5

307

3000801 Oil ruler

1

321

2064158

Oil seal cover

1

308

3000901 Oil ruler casing

1

322

3004501

O seal 35*3.1

1

309

6000121 Screw M8x30

5

323

6000168

Bearing 30205

2

310

2009201 Upper cover

1

324

2009601

Worm screw

1

311

6000166 Bearing 6010

1

325

6000337

Key 6*6*20

1

312

2009401 Gearbox shaft

1

326

3005127

Seal 25*40*8

1

313

6000102 Screw M8x20

1

327

6000170

Key 12*8*50

1

314

6000199 Washer 8

1

328

6000112

Screw M6*12

1

315

2037201 Washer

(Pulley

)

1

329

6000101

A-key 12*8*40

1

316

2009701 Pulley

1

330

6000204

Pin 8*16

1

317

2009501 Worm Gear

1

331

6000200

Washer 10*30*2

6

318

6000167 Bearing 6208

1

332

6000181

Screw M10*160

6

319

2009301 Worm Gear

cover

1

2012501 Parts of Motor Assembly (Fig.33)

400

2012501 Motor

1

406

6000192

Screw M8x35

4

401

4003101

Motor 220V

1.2KW

50HZ

(

standard

)

1

407

6000139

Washer 8x22x2

8

4002801

Motor

380V

0.75KW

50HZ

(

optional

)

0

408

6000134

Washer 10x20x2

3

4003201

Motor 110V

1.2KW

60HZ

(

optional

)

0

409

6000336

Screw M10

4

402

2012701 Motor Pulley

1

410

3003601

Washer

6

403

6000130 Screw M6*10

2

411

6000199

Washer 8

4

404

6000237 Belt A660

1

412

6000127

Screw M8

4

405

2012601 Motor Support

1

413

4004444

Capacitor

1

2065595 Parts of Body Assembly (Fig. 34)

501

2065656 Frame

1

518

6000134

Washer 10*22*2

6

502

2064852 Frame front

cover

1

519

Regulator base

1

503

3000101 Frame foot

rubber

4

520

4000701

Regulator

1

504

3005273 Robber buffer

1

521

3005080

Union IPC 4-02

2

505

6000253 Screw M6*16

5

522

2065615

Side cover

1

506

6000325 Washer

6*18*1.6

6

523

6000325

Washer 6*16*2

4

507

3005277 Robber buffer

1

524

6000198

Washer 6

4

508

2045001 Hanger

1

525

6000431

Screw M6*16

4

509

2065612 Column base

1

526

3005006

Union IPC 8-02

1

Summary of Contents for CT2880

Page 24: ...13 EXPLODED DRAWINGS Column assembly Fig 31...

Page 25: ...Turntable assembly Fig 32...

Page 26: ...Gearbox motor assembly Fig 33...

Page 27: ...Body assembly Fig 34...

Page 28: ...Pedal Assembly Fig 35...

Page 29: ...Bead Breaker Cylinder Breaker Arm Assembly Fig 36...

Page 30: ...Quick inflating system Optional Fig 37 Assemble...