Height Rider/SP Series

Operating & Safety Instructions

English/USA – 01/18

Original instructions

41

4.7.2

TOWING

To enable towing of the HR12

2x4

in case of an emergency.

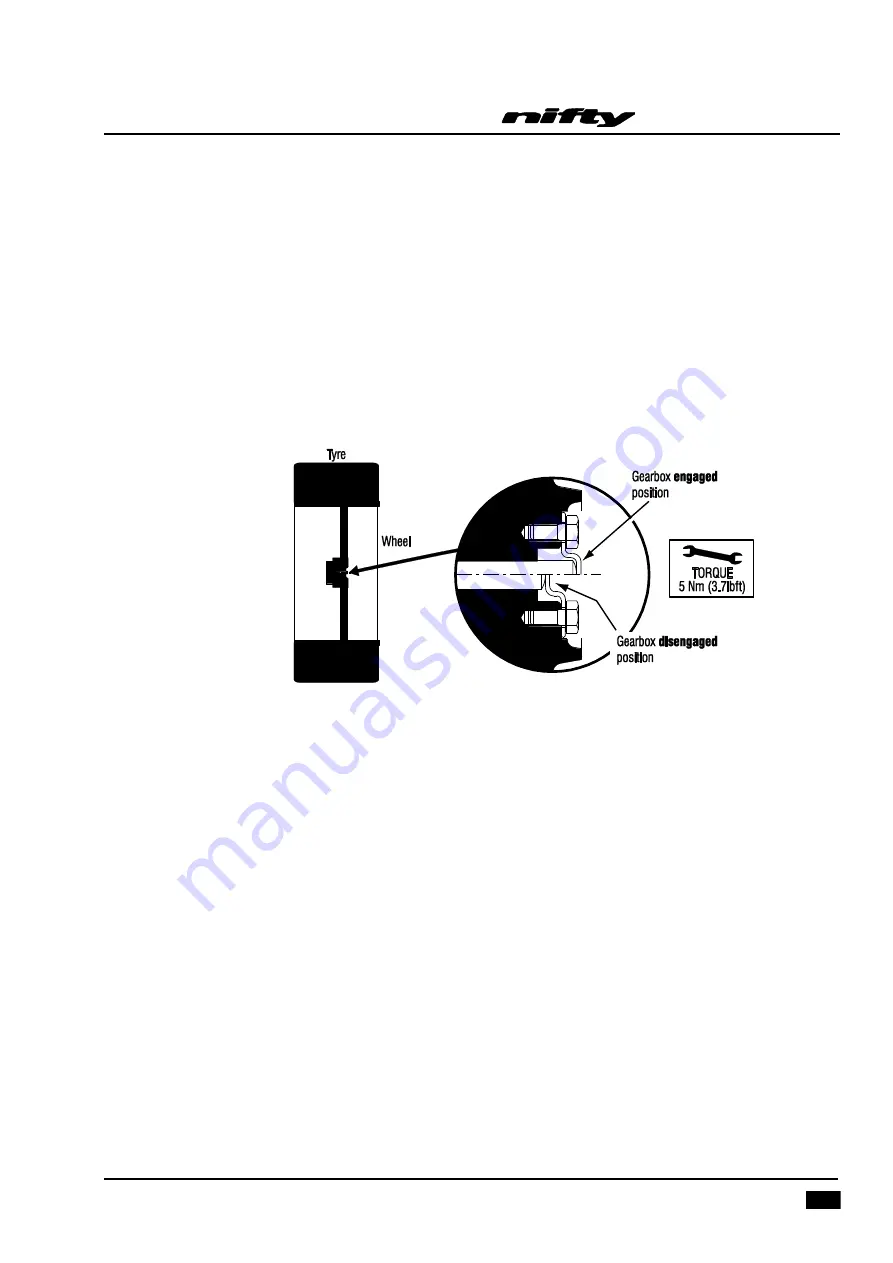

GEARBOX DISENGAGEMENT

The drive gearboxes located on the front and rear wheel hubs must be disengaged as follows;

1)

To disengage the gearbox, remove both screws from the cover plate, turn it upside down (as per

the diagram below), and re-tighten the M5 screws to a torque of 5 Nm (3.7lbft).

2)

Before attempting to re-engage the gearbox, ensure that the machine is jacked up so the relevant

wheel is clear of the ground in order to prevent damage.

Note; Damage caused by failure to

comply with this notice will not be covered by the manufacturer’s warranty.

4.7.3

CRANEAGE

1)

Observe all of the limitations relating to straps and chains stated above under ‘Transporting’.

(4.7.1)

2)

When utilising the designated lifting points never apply a ‘snatch’ load, i.e. lift slowly to take up

the load before raising. Similarly, do not drop machine when positioning after lifting.

3)

If the machine is to be lifted by crane, use the designated lifting points and observe the

recommendations regarding spreader beams. Individual drawings are available for each machine

type, on request. (See list below.)

D81790

HR15/17 4x4/Hybrid MK2

D81795

HR15N/17N

D81996

HR12NE MK2

D82069

HR12LE MK2

4.7.4

STORAGE

If being stored for any length of time without use, then the machine should be thoroughly inspected for

the following:-

1)

Grease all bearings /slides, worm drives, etc.

Summary of Contents for HR 12

Page 77: ......