JAA80351-R.3739.A

- ・AF-S DX 8-55/3.5-5.6G VR -

・

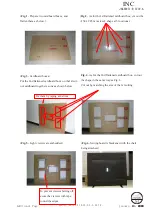

Set the zoom to "35 mm".

・

Peel ��ff t�e bac�in�� paper ��f t�e c���pan�� na�e plate (#113). Ali��n t�e index ��f t�e z����� rin�� (#52) wit�

the cutout of the company plate (#113), and mount [#113].

Company name plate

#113

Cutout

Index

・

Peel off the backing paper of the name plate (#68) and VR name plate (#69), then adhere them.

Name plate/VR name plate

#69

#68

INC

Summary of Contents for AF-S DX Nikkor 18-55mm/F3.5-5.6G VR

Page 72: ...JAA80351 R 3739 A 41 AF S DX 18 55 3 5 5 6G VR Click Close to end the procedure INC ...

Page 75: ...JAA80351 R 3739 A 44 AF S DX 18 55 3 5 5 6G VR Click Close to end the procedure INC ...

Page 79: ...JAA80351 R 3739 A 48 AF S DX 18 55 3 5 5 6G VR Click Close to end the procedure INC ...

Page 82: ...JAA80351 R 3739 A 51 AF S DX 18 55 3 5 5 6G VR Click Close to end the procedure INC ...

Page 105: ...JAA80351 R 3739 A 74 AF S DX 18 55 3 5 5 6G VR Target chart Resolution chart INC ...