JAA79651-R.3695.A

- A61 ・ AF-S DX 18-135/3.5-5.6G -

1mm

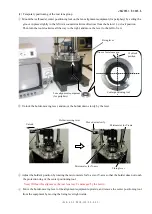

3-3: Turn the rear cover ring clockwise, which was attached to the bayonet mount. Then stop at the position as

shown in "Fig.3-1".

Fig. 3

Fig. 3-1

3-4: Fix the three locations of "Fig. 4" of the rear cover ring with the instant glue.

Fig. 4

3-6: Attach the mount rotation stopper screw at the appropriate position.

3-5: Turn the bayonet mount over. Reinforce the three locations of "Fig. 5" with the adhesive to attach the

bayonet mount and rear cover ring firmly.

Fig. 5

Summary of Contents for AF-S DX Zoom Nikkor 18-135/3.5-5.6G ED

Page 28: ...JAA79651 R 3695 A A AF S DX 18 135 3 5 5 6G Cover ring Cover ring Drip proof leather ...

Page 34: ...JAA79651 R 3695 A A 13 AF S DX 18 135 3 5 5 6G Focus key 122 2 Focus key ...

Page 49: ...JAA79651 R 3695 A A 28 AF S DX 18 135 3 5 5 6G Zoom rubber Zoom rubber Sheet Tape 132 2 ...

Page 86: ...JAA79651 R 3695 A A65 AF S DX 18 135 3 5 5 6G Target chart Resolution chart ...

Page 93: ...JAA79651 R 3695 A F1 AF S DX 18 135 3 5 5 6G 外観図 Sketch drawings ...

Page 94: ...組立図 Stracture of the Lens F2 AF S DX 18 135 3 5 5 6G JAA79651 R 3695 A ...

Page 95: ... F3 AF S DX 18 135 3 5 5 6G JAA79651 R 3695 A ...