JAA63051-R.3689.A

- A23 ・ AF-S VR MC 105/2.8G -

SWM unit

①

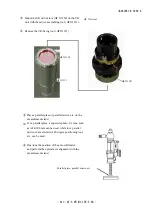

Assemble the washer (#167) and the waver washer

(#166).

Caution: The washer (#167) and the wave washer (#166)

are put with their chamfered sides downwards.

②

Fit the pin of the SWM unit in the cutout of the

focus coupling key (#87), and assemble them.

Apply to arched-top 12 parts on both sides.

#166

#167

Caution: When assembling, do NOT touch the

upper surface of the pattern.

SWM unit

#87

cutout

Pin

#148

#147

#211×4

③

Fix the three rollers (#148) with the three screws (#147).

④

Attach four pieces of the tape (#211).

#148×3

#147×3

Adhesive: Lockend B

Grease: EM-60L

Summary of Contents for AF-S VR Micro Nikkor 105mm/f2.8G

Page 13: ...JAA63051 R 3689 A D11 AF S VR MC 105 2 8G Focus index unit 83 3 GMR unit Focus index unit ...

Page 100: ...JAA63051 R 3689 A A76 AF S VR MC 105 2 8G Target chart Resolution chart ...

Page 107: ...JAA63051 R 3689 A F1 AF S VR MC 105 2 8G 外観図 Sketch drawings ...

Page 108: ...JAA63051 R 3689 A F2 AF S VR MC 105 2 8G 組立図 Structure of the Lens ...

Page 109: ...JAA63051 R 3689 A F3 AF S VR MC 105 2 8G ...

Page 110: ...JAA63051 R 3689 A F4 AF S VR MC 105 2 8G ...

Page 111: ...JAA63051 R 3689 A F5 AF S VR MC 105 2 8G ...

Page 112: ...JAA63051 R 3689 A F6 AF S VR MC 105 2 8G ...

Page 113: ...JAA63051 R 3689 A F7 AF S VR MC 105 2 8G ...