VAA31001-R.3651.A

- A14 ・ E5600 -

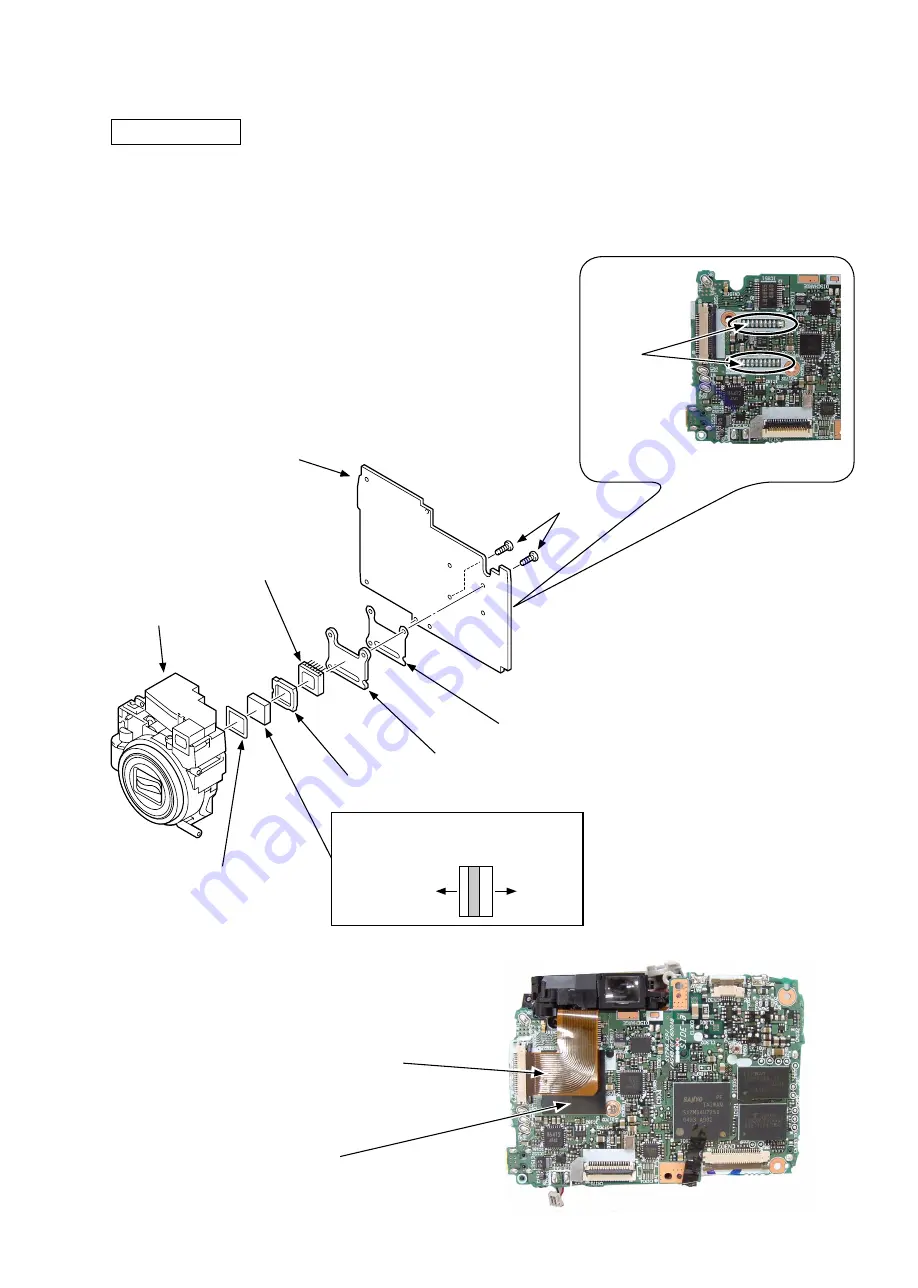

LENS UNIT

・

Set the spacer LPF [#

209

] and the optical filter [#

210

] into the lens unit.

・

As taking care about its direction, set the spacer [#

211

] into the lens unit.

・

Set the spacer insulator [#

214

], the lens mount [#

213

] and the CCD [#

212

] and solder them to the main PCB CP-

1

[#

218

]. (Fig.

1

)

・

Tighten the two screws [#

106

].

・

Adhere the spacer [#

225

].

・

Set the FPC.

FPC

Spacer [#

225

]

(Fig.

1

)

Perform

soldering.

Optical filter [#

210

]

Setting direction

Lens unit side

CCD

side

Screw [#

106

]

CCD [#

212

]

Spacer insulator [#

214

]

Lens mount [#

213

]

Spacer LPF [#

209

]

Spacer [#

211

]

Main PCB CP-

1

[#

218

]

Lens unit

Summary of Contents for Coolpix 5600

Page 10: ...VAA31001 R 3651 A D4 E5600 Discharging of main condenser 2KΩ 5W ...

Page 62: ...VAA31001 R 3651 A E1 E5600 ...

Page 63: ...VAA31001 R 3651 A E2 E5600 ...

Page 64: ...VAA31001 R 3651 A E3 E5600 ...

Page 65: ...VAA31001 R 3651 A E4 E5600 ...

Page 66: ...VAA31001 R 3651 A E5 E5600 ...

Page 67: ...VAA31001 R 3651 A E6 E5600 ...

Page 68: ...VAA31001 R 3651 A E7 E5600 ...

Page 69: ...VAA31001 R 3651 A E8 E5600 ...