- 13 -

14) Operation check 2

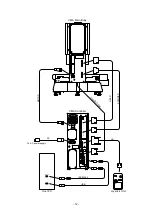

After confirming that all the procedures described above have been completed properly,

start up the entire system and check system operation.

Operation using the joystick

•

Zoom magnification adjustment operation

•

On, off, and intensity adjustment of all lights

•

CNC operation (destination coordinates can be specified by double-clicking the

counter window.)

•

Edge detection, image auto focus operation

•

Operation of Laser Auto Focus (option)

•

Confirmation of error message of output window

If the system does not operate properly, check the following:

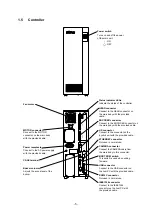

(1) Is the power cord plugged securely into the power outlet?

(2) Is the power supply capacity adequate?

(3) Is the power switch of the controller turned on?

(4) Are the cables connected properly?

(5) Are the cables for the host computer connected properly?

(6) Are all four adjustable legs of the measurement stand in firm contact with the floor

and is the stand stable?

(7) Is the main unit level?

(8) In the case the special measurement stand is not used, is the table used strong

enough?

(It is recommended that a table capable of withstanding weight of 1,000 kg or more

be used.)

(9) Are the floor strength and floor vibration parameters within the specified ranges?

(10) Are the special rubber vibration isolators used? Is each adjustable leg positioned

accurately at the center of a rubber vibration isolator?

If the system still does not operate correctly after confirming all of the above items, stop

using the system and contact your Nikon representative.

15) Calibrate the optical head.

Before conducting measurement, perform calibrations (1) through (3) described below. It

is recommended that these calibrations be performed regularly (about once a month).

* Note: Failure to calibrate the optical head will result in significant measurement errors.

(1) Magnification compensation

(2) Optical axis compensation

(3) Camera rotation compensation

Summary of Contents for HVBTR-1200

Page 2: ......