SOLUTION SYSTEM

FORM NO. 56043089 / AquaRide

™

/ BRX 700 - 37

MAJOR COMPONENTS SPECIFICATIONS

Nozzle and Pump Data

Flow Rate

Components

GPM / Working Pressure

Nozzle (A) “Maintenance”

.55 GPM

Spec. .057” orifi ce diameter

Hardened Stainless Steel

Nozzle tip I.D. QSTK-SS-3.0

Nozzle (B) “Restoration”

.98 GPM

Spec. .091”orifi ce diameter

Brass

Nozzle tip I.D. QTKA-BR7.5

Pump Specifi cations

Pressure relief switch opens at 100 PSI

Max.

fl ow rate 1.6 GPM

Max. current 3A (average current 2.7A)

NOZZLE MAINTENANCE

See Figure 4. To inspect and clean both nozzles no tools are needed. First remove the Wing Nut (G) that secures the nozzle bracket (tree) and

pull it from the brush housing slots with the hoses still connected.

To remove a nozzle to clean or replace just grip the nozzle tip and at the same time press in and twist it a 1/4 turn to separate it from the nozzle

body. Note: Suggested once a week to inspect and clean nozzles.

Clean by soaking nozzles overnight in a full strength vinegar solution or properly diluted and handled meratic acid solution to remove build up of

chemical deposits. Note: Do not ream out (increase) the orifi ce by cleaning with a drill bit. As this will affect the nozzle working pressure and spray

pattern.

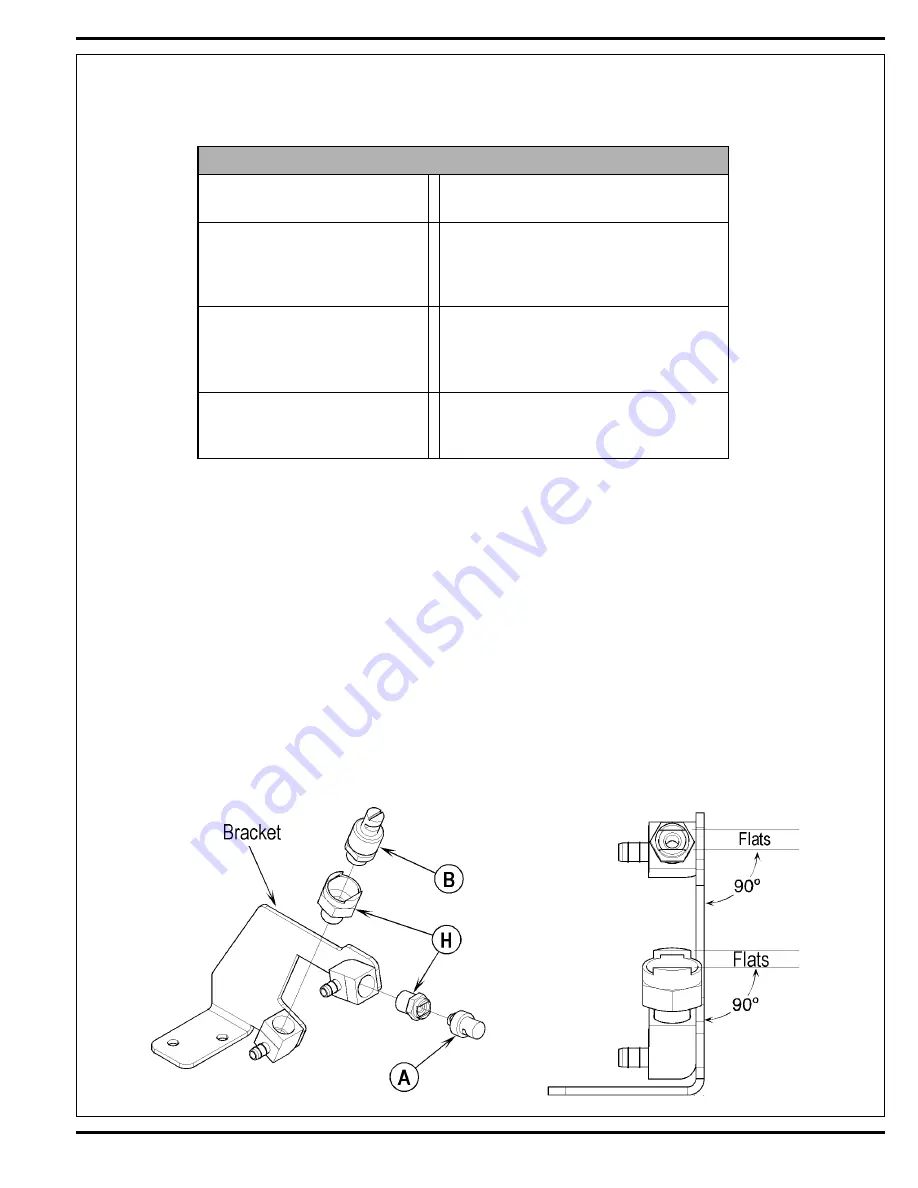

NOZZLE FIXTURE INSTALLATION

1 Apply small amount of thread sealant (Loctite #242-blue) to the fi xture threads.

2 See Figure 3. Thread the Nozzle Fixtures (H) into each brass barb.

3 Position

nozzle

fi xture as shown (nozzle fi xture fl at must be 90º to bracket arm).

FIGURE 3

Summary of Contents for 56314019

Page 7: ...FORM NO 56043089 AquaRide BRX 700 5 SPECIFICATIONS ...

Page 46: ...44 FORM NO 56043089 AquaRide BRX 700 RECOVERY SYSTEM FIGURE 3 ...

Page 49: ...RECOVERY SYSTEM FORM NO 56043089 AquaRide BRX 700 47 FIGURE 5 FIGURE 6 ...

Page 55: ...ELECTRICAL SYSTEM FORM NO 56043089 AquaRide BRX 700 53 FIGURE 4 FIGURE 3 ...

Page 72: ...70 FORM NO 56043089 AquaRide BRX 700 ELECTRICAL SYSTEM Drive Motor Breakdown ...

Page 79: ......

Page 82: ...www nilfisk advance com 2005 ...