58 - FORM NO. 56043089 / AquaRide

™

/ BRX 700

ELECTRICAL SYSTEM

FUNCTIONAL OVERVIEW OF MAIN CONTROL BOARD

The primary function of the main control board E1 is to position the scrubbing brush(s) with respect to the fl oor surface using a lift actuator motor

to maintain the correct brush pressure and current draw of the brush motor(s). When either the maintenance or restoration scrub mode switch is

depressed this will lower the scrub deck to the operating position and by activating the foot pedal start the brush motor. The controller is continuously

monitoring the current to the brush motor and when it senses a current draw out of the desired range it automatically raises or lowers the brush deck

by turning on the brush actuator motor. This process is repeated until the brush motor is shut off. The controller also manages the other supportive

systems such as the extract deck in reverse lift, solution on/off, and vacuum motor. Note: See the Know Your Machine system in this manual for a

complete explanation of the machine’s operation.

The secondary function of the main control is to detect any system failures and display an error code on the hour meter display or store it in the main

control board’s recall memory mode. The error code(s) are used to help the serviceperson determine the fault and to quickly guide in repairing a

specifi c system malfunction. Note: See the Troubleshooting Guide for further information.

An additional special feature of the main control board is to change program settings for a set of specifi c machine functions. See the Main Control

Board Special Program Options section in this manual for further information.

TROUBLESHOOTING GUIDE

Any error codes detected by main control board will be displayed on the hour meter LED display as they occur. If more than one-error exists the

display will sequence through the error codes at one-second intervals. The error display will show on the hour meter as the letter E followed by a

two-digit code. EX: E03 would be a drive system fault. When troubleshooting any “Fault Description” noted with a double asterisk (**) follow

the instructions for temporarily disabling the control boards special fault detection program. See the Main Control Board Special Program

Options section in this manual.

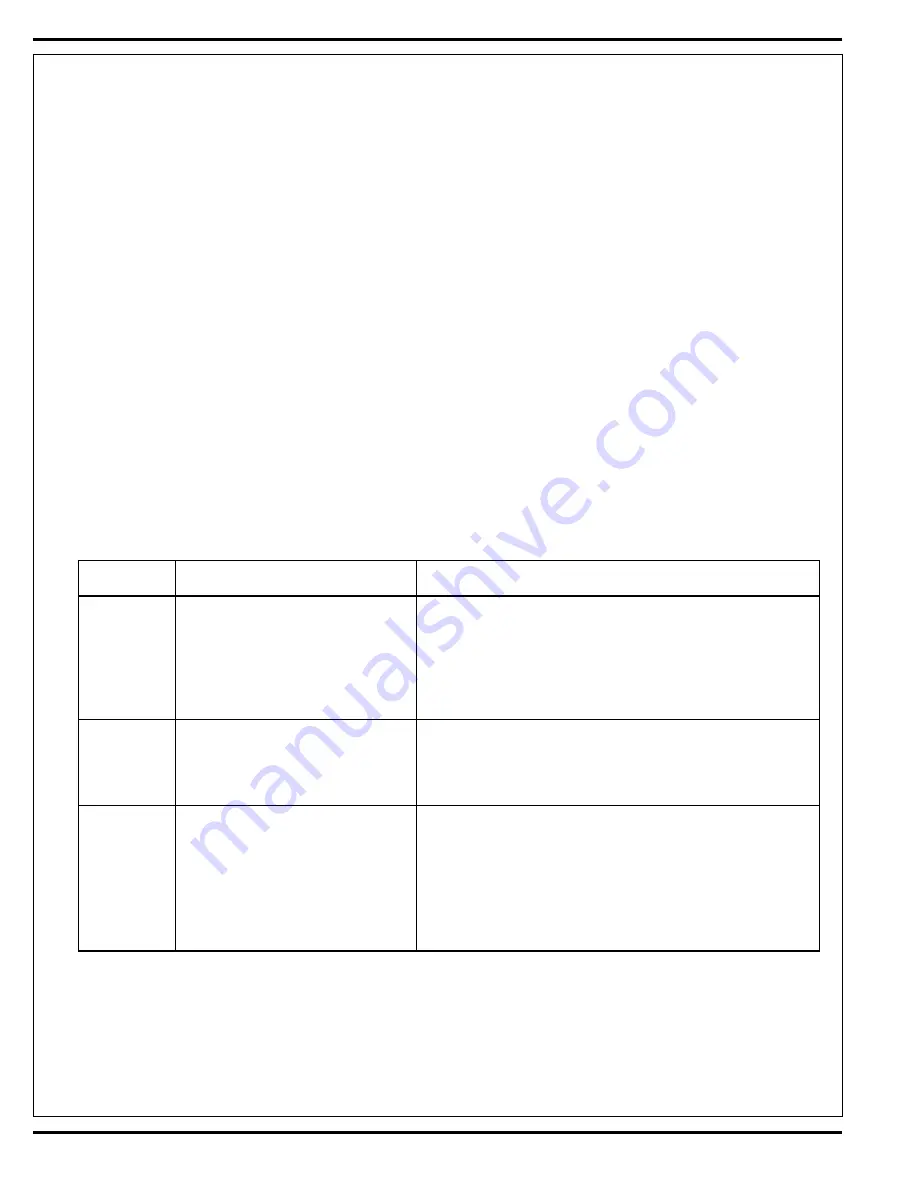

MAIN CONTROLLER ERROR CODES

Error Code

Fault Description

Troubleshooting Action

E03

Drive system fault

1. Check for a tripped drive motor circuit breaker (45 amp). Investigate

reason for possible mechanical over load. Examples: sticking brakes,

parking brake not released, prolonged ramp climbing. 2. Observe the

green fl ashing wand indicator light (location operator panel) then see

Curtis drive motor controller section to further troubleshoot the drive

system (Table 1).

E04

Scrub deck lift actuator overload

1. Check for binding or frozen brush lift linkage and

normal current load 1 - 2.5 Amps

excessive weight on brush deck. 2. Check for short circuit*

max. current load 6 Amps

in brush motor and wiring. Repair or replace.

max. current no load 1.4 Amps

E06

Scrub motor overload

1. Check for binding in rotation of brushes or improper brush lift actuator

operation. 2. Check the negative supply cable at the brush motor for a

wiring problem or improper modifi cations and also the small YEL/VIO

current sense wire. 3. Check to see that the proper “Scrub Deck Motor

Type” is selected*** (extract or sweep extract). 4. Check for short

circuit* in brush motor or wiring. 5. Check excessive belt tension and

idler bearing.

*** See the Main Control Board Special Program Options section to activate the “Scrub Deck Motor Type” Selection function.

Summary of Contents for 56314019

Page 7: ...FORM NO 56043089 AquaRide BRX 700 5 SPECIFICATIONS ...

Page 46: ...44 FORM NO 56043089 AquaRide BRX 700 RECOVERY SYSTEM FIGURE 3 ...

Page 49: ...RECOVERY SYSTEM FORM NO 56043089 AquaRide BRX 700 47 FIGURE 5 FIGURE 6 ...

Page 55: ...ELECTRICAL SYSTEM FORM NO 56043089 AquaRide BRX 700 53 FIGURE 4 FIGURE 3 ...

Page 72: ...70 FORM NO 56043089 AquaRide BRX 700 ELECTRICAL SYSTEM Drive Motor Breakdown ...

Page 79: ......

Page 82: ...www nilfisk advance com 2005 ...