FORM NO. 56043097 / Adgressor

™

/ BR 850S, 850CS, 950S, 950CS, 1050S, 1050CS - 51

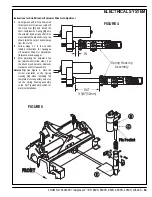

ELECTRICAL SYSTEM

BATTERY MAINTENANCE

Proper maintenance of electric vehicle batteries can greatly extend their life. Well-maintained batteries may last up to 3 years, but failure after 1 year

is common if maintenance has been poor.

There are 3 simple rules for good battery maintenance:

•

Maintain Proper Electrolyte Level (Weekly) - Use distilled water in batteries whenever possible. If batteries are discharged, add just enough

water to cover the plates in each cell. If batteries are fully charged, fi ll each cell to the bottom of the fi ller tube. Do not over-fi ll the batteries!

Do not add acid to batteries!

•

Keep the Batteries Charged (Weekly) - Batteries should be charged each time that a machine is used for more than 1 hour. Machine

operators should open the battery compartment cover for charging, to avoid a concentrated build-up of hydrogen gas. Operators should follow

the instructions provided with their specifi c battery charger, to determine how long the batteries should be charged. Even when a machine is

stored, the batteries should be charged once a month to prevent the batteries from “sulfating”. Almost all battery caps are vented, so there’s

no need to loosen or remove them for charging.

•

Keep the Batteries Clean (Monthly) - Use a damp cloth to wipe dirt from the top of the batteries. Battery terminals must be clean and tight.

If the tops of the batteries are wet after charging, the batteries have probably been over-fi lled or over-charged. Note: If there is acid on the

batteries, wash the tops of the batteries with a solution of baking soda and water (2) tablespoons of baking soda to 1 quart of water.

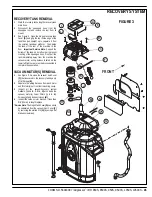

BATTERY TESTING

A battery problem is usually recognized by the machine operator, as a decrease in the machine’s running time. This condition is usually caused by

one or more “dead cells” in the battery system that is, one or more cells that is putting out less voltage than the other cells.

Note: Always charge batteries before testing.

There are 2 ways to fi nd a dead cell:

•

Use a hydrometer to check the specifi c gravity (or “state of charge”) of the fl uid in each cell. A dead cell is one that reads 50 points (or more)

lower than the other cells.

•

Use a volt meter to check the voltage of each battery with the scrub and drive motors running. The battery with the dead cell will read 1 or 2

volts lower than the other batteries in the system.

If the batteries in the machine are more than 1 year old, it’s usually best to replace the whole set, rather than replacing just one battery.

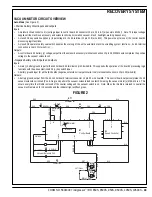

The chart below shows the approximate “percent charged” of an electric vehicle battery at various specifi c gravity values, corrected to 80°F

(26.7°C).

APPROXIMATE STATE OF CHARGE

1.265

Initial

Charged

Full

Charge

100%

1.265

75%

1.225

50%

1.190

25%

1.155

Discharged

1.120

Summary of Contents for Adgressor BR 1050CS

Page 81: ......

Page 82: ...www nilfisk advance com 2006 ...