14 - FORM NO. 56043051 / Retriever

™

2060

SWEEPING SYSTEM

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

MAIN BROOM MAINTENANCE

Since the Main Broom Motor always turns in the same direction, the bristles on the broom eventually become curved, reducing sweeping

performance. Sweeping performance can be improved by removing the broom and turning it around (end-for-end). This procedure,

known as “rotating” the main broom, should be done once every 30 hours of operation.

The main broom should be replaced when the bristles are worn to a length of 2-1/2 inches (6.35 cm). The main broom stop must be

re-adjusted when the broom is replaced.

NOTE: The machine should be stored with the Main Broom in the raised position.

WARNING!

The engine must not be running when performing this procedure.

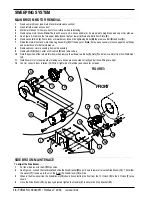

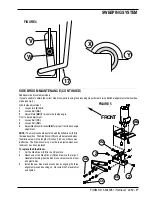

To Rotate or Replace the Main Broom...

1

Turn the Ignition Key Switch (52) OFF.

2

Put the Main Broom Raise / Lower (ON / OFF) Lever (53) in the DOWN position.

3

Open the Main Broom Access Door (15).

4

Remove the large T-Bolt from the side of the broom idler arm. Pivot the idler arm assembly out of the main broom core.

5

Pull the main broom out of the broom housing and remove any string or wire wrapped around it. Also inspect the skirts at the front,

back and sides of the broom housing. The skirts should be replaced or adjusted if they are torn or worn to a height of more than

1/4 inch (6.35 mm) off the ground.

6

Turn the broom around (end-for-end) and slide it back into the broom housing. Make sure that the lugs on the broom drive hub

(left side) engage the slots in the broom core.

7

Swing the idler arm assembly back into the broom core and re-install the T-Bolt that holds the idler arm in place.

8

Close and latch the Main Broom Access Door (15).

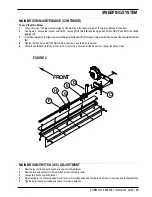

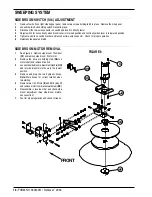

To Adjust the Main Broom Height...

1

Drive the machine to an area with a level floor and set the

parking brake.

2

Pull the Main Broom Raise / Lower (ON/OFF) Lever (53)

back and slide to the left and up to lower and start the

main broom. DO NOT move the machine.

3

Let the main broom run in place for 1 minute. This allows

the broom to polish a “strip” on the floor. After 1 minute,

raise the broom, release the parking brake and move

the machine so that the polished strip is visible.

4

Inspect the polished strip on the floor. If the strip is less

than 2 inches (5.08 cm) or more than 3 inches (7.62 cm)

wide, the broom needs to be adjusted.

5

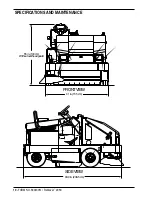

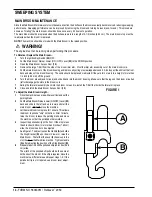

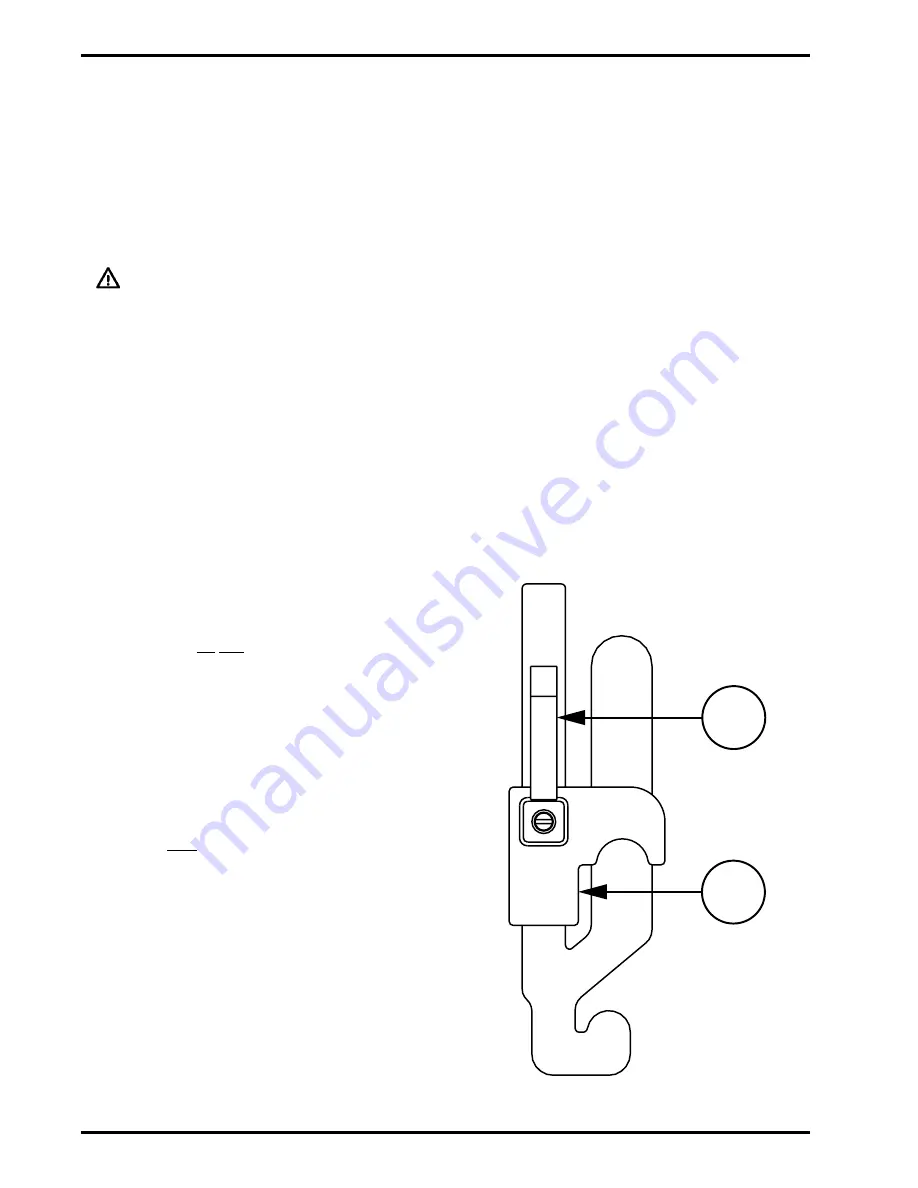

See Figure 1. To adjust, loosen the Handle (A) and slide

the Stop Bracket (B) up or down to lower or raise the

Main Broom. The farther the Lever (5) travels up in the

slot, the lower the Main Broom will be. Tighten Handle

(A) after adjusting the position of the Stop Bracket (B).

6

Repeat steps 1-5 until the polished strip is 2 inches (5.08

cm) wide.

The width of the polished strip should be the same at

both ends of the broom. If the strip is tapered, move the

machine to a different area and repeat steps 1-5. If the

polished strip is still tapered, see broom level adjust-

ment.

FIGURE 1

A

B

Summary of Contents for Advance Retriever 2060

Page 87: ...4 99 Form No 56040696 page 2 A 3 B C D 5 1 2 6...

Page 94: ...6 99 revised 3 00 Form No 56040702 page 2 5 3 2 6 6 5 3 4 1 2...

Page 111: ...9 00 Form No 56040733 page 2 of 3 Diesel H FRONT M K L N R W P O T S J Q O P U V FIGURE 1...

Page 128: ...PROGRAM PURPOSE and OBJECT ZENITH FUEL SYSTEMS Page 1 1 5 48 7 0 1 2 3 4 5 0 50...

Page 133: ...ZENITH FUEL SYSTEMS Page 5 1 5 0 50 A 50 4 4 B 8 6 A C D FIG 5 1...

Page 134: ...ZENITH FUEL SYSTEMS Page 5 2 6 5 8 0 8 2 0 2 0 2 E F 0 D 50 4 C D 5 5 5 5 6 6 2 0 6 FIG 5 2...

Page 139: ...Fuel Enrichment 4 6 6 50 5 5 6 A 50 5 0 0 ZENITH FUEL SYSTEMS Page 5 7...

Page 144: ...ZENITH FUEL SYSTEMS INC Page 5 12 3F 6 6 H J 3F FIG 5 19 6 G 6 FIG 5 20...

Page 147: ...ZENITH FUEL SYSTEMS Page 6 2 A A 1 6 FIG 6 1...

Page 148: ...ZENITH FUEL SYSTEMS Page 6 3 5 2 3 0 0 1 4 4 B 6 6 6 4 4 3 6 6 6 9 6 6...

Page 149: ...ZENITH FUEL SYSTEMS Page 7 2 8 2...

Page 150: ...ZENITH FUEL SYSTEMS Page 7 3 8 2...

Page 153: ...ZENITH FUEL SYSTEMS Page 9 3...

Page 160: ...ZENITH FUEL SYSTEMS Page 9 11 6 6 9 8 2...

Page 163: ...ZENITH FUEL SYSTEMS Page 9 14 6 6 9 8 Continued...