32 - FORM NO. 56043051 / Retriever

™

2060

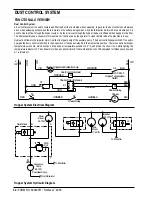

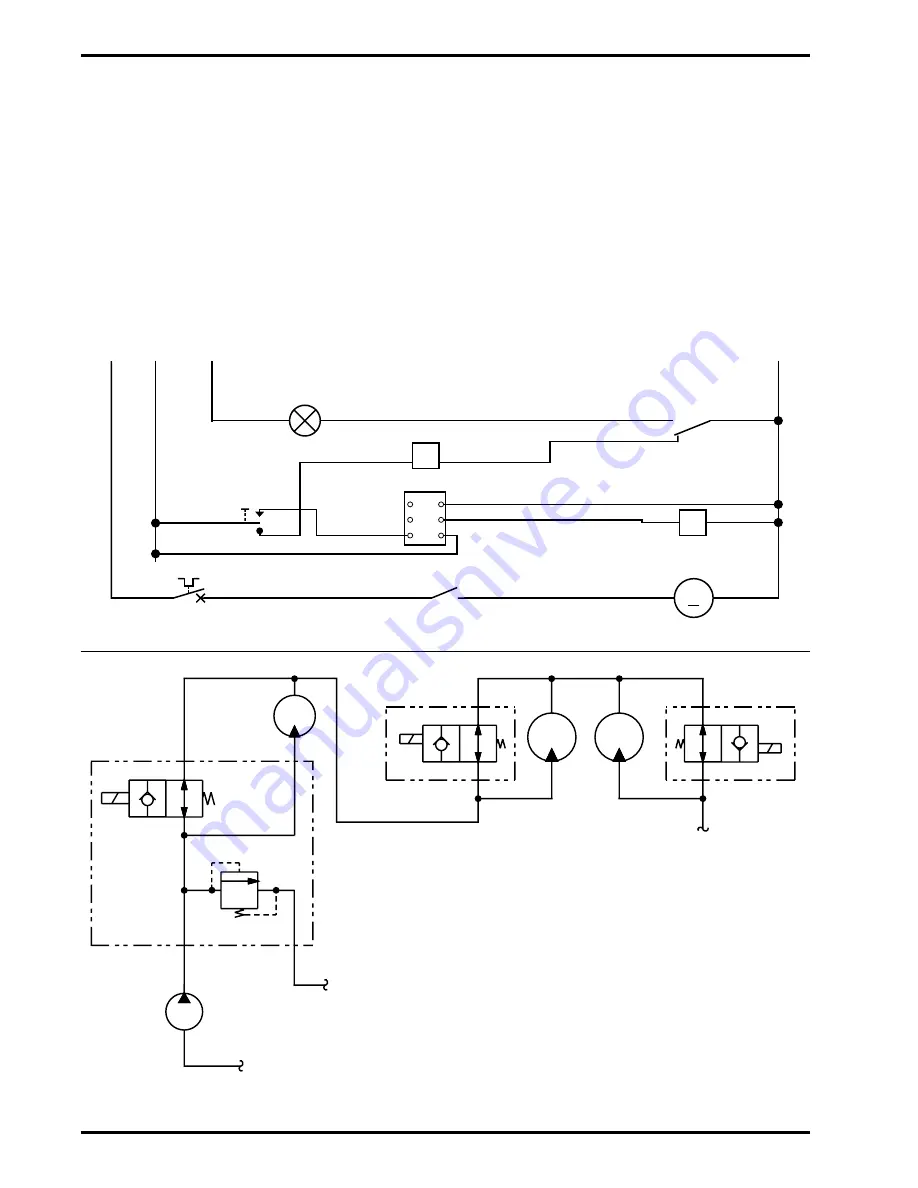

DUST CONTROL SYSTEM

ORN/RED

_

12V

BLK

S7

BLK

RED

Shaker Relay

K2

Shaker Relay

BLK

ORN

ORN

E1

BLK

Shaker

RED

+

12V

M

K2

F5

GRN/BLK

M2

2

1

3

4

5

6

RED/BRN

BLK

Shaker Timer (Optional)

1

2

3

L2

WHT/RED

S6

140 DEG. F

Hopper Temperature

Switch

H5

VIO

WHT/ORN

Hopper Heat Indicator Lamp

ORN

VIO

Dust Control Solenoid

Dual Gear Pump

Accessory

Pump

.84 CIR

P

T

8.7

GPM

2500

PSI

B

A

Relief Block

L3

Main

Broom

4.5 CIR

Side

Broom

17.9 CIR

To Manifold

From Reservoir

L4

L2

Impeller

.323 CIR

To Manifold

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

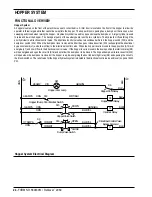

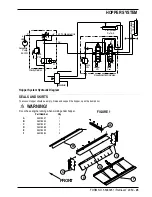

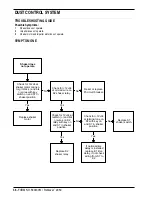

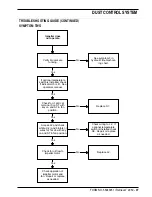

FUNCTIONAL OVERVIEW

Dust Control System

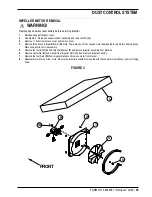

A dust control system is used to contain and filter the dust that is created when sweeping. In general, the dust control should always

be on when sweeping except when there is water on the surface being swept. A hydraulic impeller motor with a fan mounted on it is

used to create airflow through the hopper system. As the air moves through the hopper the dust is lifted and then trapped in the filter.

The filter assembly has a shaker motor mounted on it that is used by the operator to clean the filter when the machine is in use.

Hydraulic oil flows to the impeller motor from the front gear pump of the auxiliary pump. The dust control/shaker switch S7 is used to

energize the dust control solenoid L2 in the on position or the shaker relay K2 in the momentary position. There is an optional hopper

temperature switch S6, which will open if the hopper temperature exceeds 140° F, and break the circuit to L2 while lighting the

temperature indicator H5. The shaker motor has an optional timer E1 that will keep the coil of K2 energized for fifteen seconds when

S7 is turned off.

Hopper System Electrical Diagram

Hopper System Hydraulic Diagram

Summary of Contents for Advance Retriever 2060

Page 87: ...4 99 Form No 56040696 page 2 A 3 B C D 5 1 2 6...

Page 94: ...6 99 revised 3 00 Form No 56040702 page 2 5 3 2 6 6 5 3 4 1 2...

Page 111: ...9 00 Form No 56040733 page 2 of 3 Diesel H FRONT M K L N R W P O T S J Q O P U V FIGURE 1...

Page 128: ...PROGRAM PURPOSE and OBJECT ZENITH FUEL SYSTEMS Page 1 1 5 48 7 0 1 2 3 4 5 0 50...

Page 133: ...ZENITH FUEL SYSTEMS Page 5 1 5 0 50 A 50 4 4 B 8 6 A C D FIG 5 1...

Page 134: ...ZENITH FUEL SYSTEMS Page 5 2 6 5 8 0 8 2 0 2 0 2 E F 0 D 50 4 C D 5 5 5 5 6 6 2 0 6 FIG 5 2...

Page 139: ...Fuel Enrichment 4 6 6 50 5 5 6 A 50 5 0 0 ZENITH FUEL SYSTEMS Page 5 7...

Page 144: ...ZENITH FUEL SYSTEMS INC Page 5 12 3F 6 6 H J 3F FIG 5 19 6 G 6 FIG 5 20...

Page 147: ...ZENITH FUEL SYSTEMS Page 6 2 A A 1 6 FIG 6 1...

Page 148: ...ZENITH FUEL SYSTEMS Page 6 3 5 2 3 0 0 1 4 4 B 6 6 6 4 4 3 6 6 6 9 6 6...

Page 149: ...ZENITH FUEL SYSTEMS Page 7 2 8 2...

Page 150: ...ZENITH FUEL SYSTEMS Page 7 3 8 2...

Page 153: ...ZENITH FUEL SYSTEMS Page 9 3...

Page 160: ...ZENITH FUEL SYSTEMS Page 9 11 6 6 9 8 2...

Page 163: ...ZENITH FUEL SYSTEMS Page 9 14 6 6 9 8 Continued...