50 - FORM NO. 56043051 / Retriever

™

2060

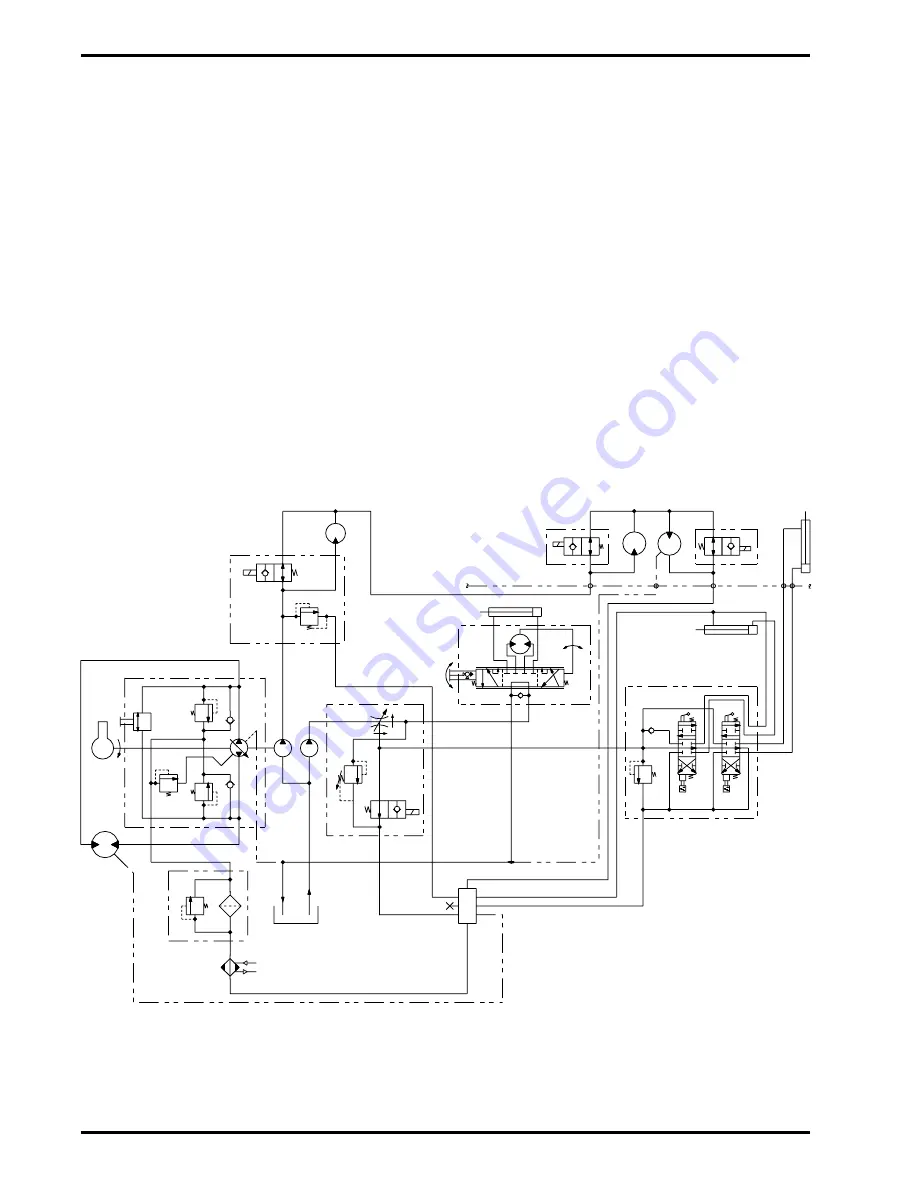

HYDRAULIC SYSTEM

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

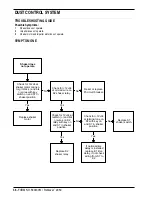

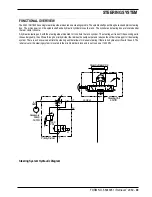

FUNCTIONAL OVERVIEW

Hydraulic system

The heart of the hydraulic system is the hydraulic pump assembly mounted on the back of the engine. This pump is directly coupled

to the engine crankshaft and actually consists of two separate pumps, a propulsion pump and an accessory pump.

The propulsion pump is a variable displacement piston pump used to drive the wheel motor only. The pedal in the operator’s compartment

uses a cable to move an arm on the side of the propulsion pump. The position of this arm determines the stroke of the pistons in the

pump, thereby controlling the volume and direction of the oil flowing to the wheel drive motor.

The accessory pump is mounted on the back of the propulsion pump. This pump provides the oil flow to power all the other hydraulic

systems on the machine. The 2060 / SR 1800 utilizes a dual gear accessory pump to provide two different flow rates to two different

hydraulic circuits. Since this pump is also directly coupled to the engine crankshaft (through the propulsion pump), the volume of oil

delivered by the pump will be determined by the speed (RPM) of the engine.

Maintaining the proper engine speed is essential for performance from the hydraulic system and the machine in general. If the engine

runs to slowly, the accessory pump will not provide the proper oil flow to run the motors at the correct speed and the machine will not

perform properly. If the engine runs to fast the pump will deliver too much oil, causing excessive system pressure and possibly damaging

the system components.

The 2060 / SR 1800 uses a fuel injection system, for both gas and propane models, that will control the engine speed. See the ENGINE

SYSTEM section of this manual for further information.

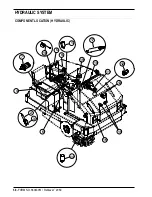

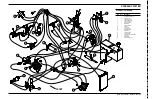

Complete Hydraulic Diagram

OIl Cooler

25 PSI

Return Filter

Hydrostatic 2.49 CIR

Wheel Motor

24.0 CIR

249 RPM

0-9 MPH

S

A

D

Reservoir

11 Gal

SAE 10W30

Ford Engine

1.3L 2400 RPM

Bypass

(Towing)

Valve

B

P

T

Dual

Gear

Pump

8.7

GPM

P

5.2

GPM

1500

PSI

Priority Divider

T

L1

DV

ST

2.0 GPM

T

P

L

R

Steering Unit

4.5 CIR

Steer Cylinder 2 X 6

Hopper

L4

Side

Broom

17.9 CIR

Impeller

.323 CIR

L2

Door Cylinder

1.5 X 4.5

Open

Lift Cylinder

3 X 16.5

A

B

C

D

Dump

Door

Hopper

Lift

2400

PSI

T

Directional Control Valve

A

B

L3

Relief Block

2500

PSI

Main

Broom

4.5 CIR

Manifold

Accessory

Pump

.50

CIR

.84

CIR

B

A

Summary of Contents for Advance Retriever 2060

Page 87: ...4 99 Form No 56040696 page 2 A 3 B C D 5 1 2 6...

Page 94: ...6 99 revised 3 00 Form No 56040702 page 2 5 3 2 6 6 5 3 4 1 2...

Page 111: ...9 00 Form No 56040733 page 2 of 3 Diesel H FRONT M K L N R W P O T S J Q O P U V FIGURE 1...

Page 128: ...PROGRAM PURPOSE and OBJECT ZENITH FUEL SYSTEMS Page 1 1 5 48 7 0 1 2 3 4 5 0 50...

Page 133: ...ZENITH FUEL SYSTEMS Page 5 1 5 0 50 A 50 4 4 B 8 6 A C D FIG 5 1...

Page 134: ...ZENITH FUEL SYSTEMS Page 5 2 6 5 8 0 8 2 0 2 0 2 E F 0 D 50 4 C D 5 5 5 5 6 6 2 0 6 FIG 5 2...

Page 139: ...Fuel Enrichment 4 6 6 50 5 5 6 A 50 5 0 0 ZENITH FUEL SYSTEMS Page 5 7...

Page 144: ...ZENITH FUEL SYSTEMS INC Page 5 12 3F 6 6 H J 3F FIG 5 19 6 G 6 FIG 5 20...

Page 147: ...ZENITH FUEL SYSTEMS Page 6 2 A A 1 6 FIG 6 1...

Page 148: ...ZENITH FUEL SYSTEMS Page 6 3 5 2 3 0 0 1 4 4 B 6 6 6 4 4 3 6 6 6 9 6 6...

Page 149: ...ZENITH FUEL SYSTEMS Page 7 2 8 2...

Page 150: ...ZENITH FUEL SYSTEMS Page 7 3 8 2...

Page 153: ...ZENITH FUEL SYSTEMS Page 9 3...

Page 160: ...ZENITH FUEL SYSTEMS Page 9 11 6 6 9 8 2...

Page 163: ...ZENITH FUEL SYSTEMS Page 9 14 6 6 9 8 Continued...