54 - FORM NO. 56043051 / Retriever

™

2060

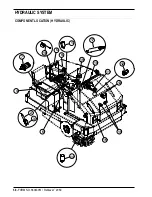

HYDRAULIC SYSTEM

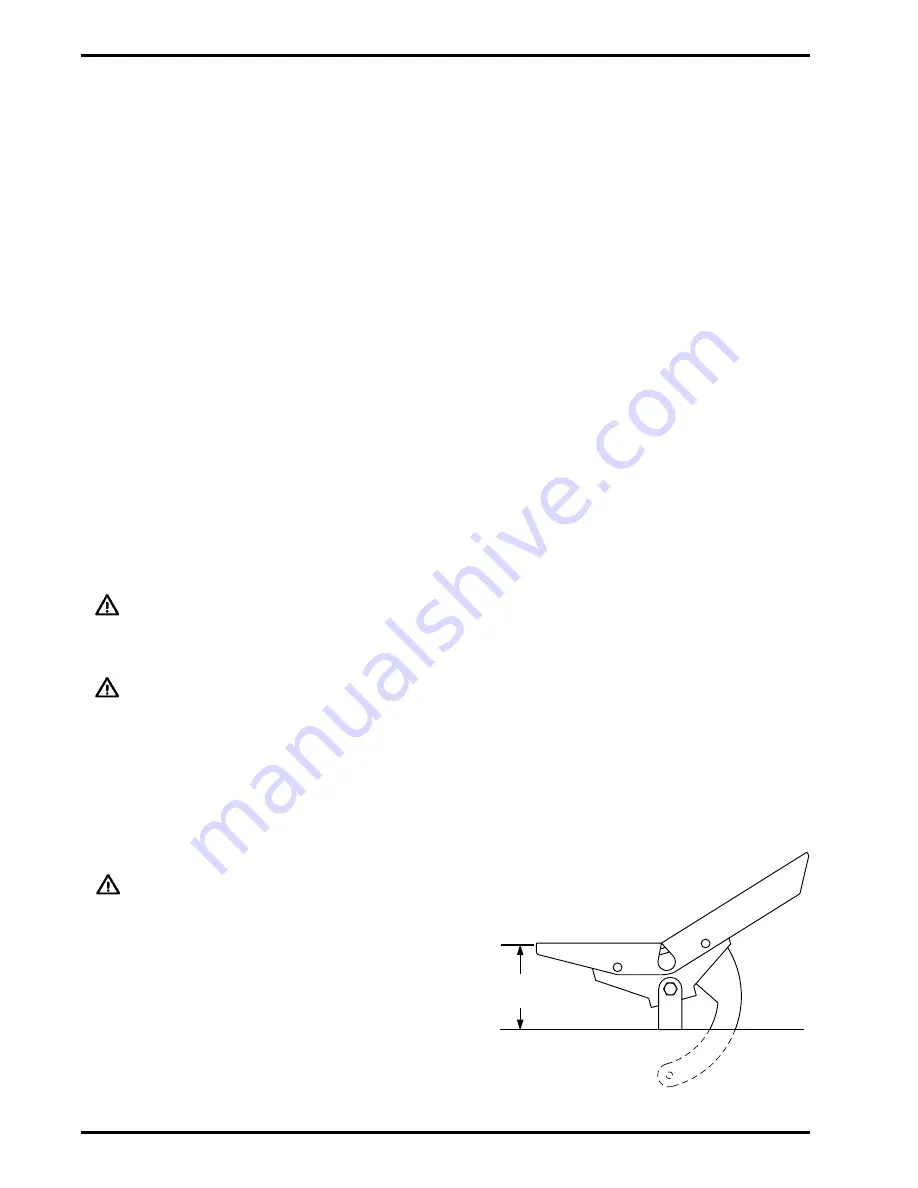

3.25"

(83 mm)

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

FUNCTIONAL OVERVIEW

Drive pedal system

The drive pedal has a cable connected to a Hydroback centering assembly that is adjusted to return the forward/reverse drive pedal to

the neutral position. This device uses a heavy spring enclosed in a plastic container to return the pump arm to its center of travel. The

result is no hydraulic oil pumped to the drive motor (neutral) allowing for safe machine operator control.

There is an additional cable that runs from the hopper to a weldment mounted by the propulsion pump arm. When the hopper is raised

the cable will move the actuator weldment, which limits the amount of travel the propulsion pump arm can move. The purpose of this

design is to not allow the machine to be operated at full speed with the hopper in the raised position.

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

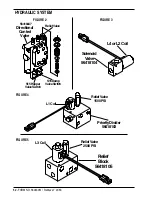

HYDROBACK AND CABLE ASSEMBLY REPLACEMENT

1

Access cable at foot pedal end by opening right side broom door.

2

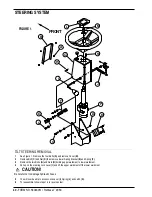

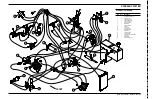

See Figure 7. Remove Cotter Pin (A) and Pin (B) from Clevis (C).

3

Loosen lock nut and remove Clevis (C) from cable.

4

Loosen cable connector Nuts (D) and remove cable from mounting bracket.

5

Pull cable end through opening, toward the rear of the machine.

6

Open the left front service door, lift and move circuit breaker assembly to access the propulsion pump linkage and remove Cotter

Pin (E) and Pin (F) from Clevis (G).

7

Loosen lock nut and remove Clevis (G) and lock nut from cable.

8

Loosen the two connector Nuts (H) and remove Cable (I) and Hydroback (J) from Mount (K).

9

Pull Hydroback and cable assembly through the machine opening. NOTE: If installing a new cable you may want to tape it to pedal

end of the cable and use the old cable to feed the new cable through opening.

10

To separate the Hydroback from the cable, hold Hydroback and unthread the rear swivel fitting from the cable conduit. The

hydroback spring housing can now be unthreaded from the cable end. NOTE: To overcome a housing that may be difficult, double

nut the cable ends to stop the cable from spinning then grip the smaller metal housing with locking pliers and unthread (ccw).

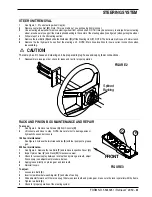

WARNING!

For correct neutral centering operation, install the Hydroback on the output end of the push-pull cable.

11

Install the new Hydroback/cable assembly in reverse order.

CAUTION!

After installing or servicing the Hydroback or drive pedal cable follow the steps in the Hydroback/drive pedal neutral

adjustment section.

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

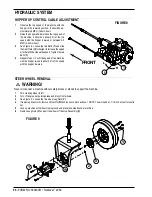

HYDROBACK DRIVE PEDAL NEUTRAL ADJUSTMENT

When servicing the drive system always check for any machine creeping (movement) in the neutral position. The machine must not

move in either forward or reverse after the drive pedal is released. If creeping is experienced the neutral position on the Hydroback must

be adjusted.

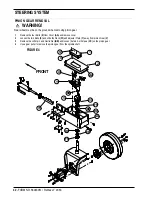

WARNING!

Use jack stands to support the machine when setting the neutral adjustment.

1

Block the front wheels. Jack up machine until the rear drive wheel

is off the floor. Place supports under the rear of the machine.

2

Open right side broom access door.

3

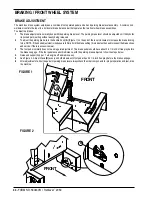

Adjust the two connector Nuts (D) (Figure 7) until the rear of the foot

pedal is 3.25” (83 mm) from the floor plate as shown in figure 6.

4

With the rear wheel off the floor, the machine supported and the front

wheels blocked, start the engine.

FIGURE 6

5

With the foot pedal in the neutral position, see if the drive wheel is moving. Operate the pedal

forward and reverse several times, make sure the pedal returns to neutral and the drive

wheel stops moving.

Summary of Contents for Advance Retriever 2060

Page 87: ...4 99 Form No 56040696 page 2 A 3 B C D 5 1 2 6...

Page 94: ...6 99 revised 3 00 Form No 56040702 page 2 5 3 2 6 6 5 3 4 1 2...

Page 111: ...9 00 Form No 56040733 page 2 of 3 Diesel H FRONT M K L N R W P O T S J Q O P U V FIGURE 1...

Page 128: ...PROGRAM PURPOSE and OBJECT ZENITH FUEL SYSTEMS Page 1 1 5 48 7 0 1 2 3 4 5 0 50...

Page 133: ...ZENITH FUEL SYSTEMS Page 5 1 5 0 50 A 50 4 4 B 8 6 A C D FIG 5 1...

Page 134: ...ZENITH FUEL SYSTEMS Page 5 2 6 5 8 0 8 2 0 2 0 2 E F 0 D 50 4 C D 5 5 5 5 6 6 2 0 6 FIG 5 2...

Page 139: ...Fuel Enrichment 4 6 6 50 5 5 6 A 50 5 0 0 ZENITH FUEL SYSTEMS Page 5 7...

Page 144: ...ZENITH FUEL SYSTEMS INC Page 5 12 3F 6 6 H J 3F FIG 5 19 6 G 6 FIG 5 20...

Page 147: ...ZENITH FUEL SYSTEMS Page 6 2 A A 1 6 FIG 6 1...

Page 148: ...ZENITH FUEL SYSTEMS Page 6 3 5 2 3 0 0 1 4 4 B 6 6 6 4 4 3 6 6 6 9 6 6...

Page 149: ...ZENITH FUEL SYSTEMS Page 7 2 8 2...

Page 150: ...ZENITH FUEL SYSTEMS Page 7 3 8 2...

Page 153: ...ZENITH FUEL SYSTEMS Page 9 3...

Page 160: ...ZENITH FUEL SYSTEMS Page 9 11 6 6 9 8 2...

Page 163: ...ZENITH FUEL SYSTEMS Page 9 14 6 6 9 8 Continued...