4/99 revised 8/01 Form No. 56040693

(page 2 of 6)

5

55

55

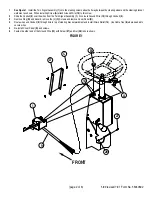

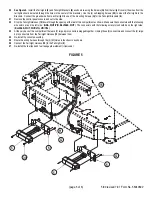

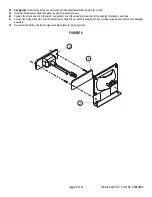

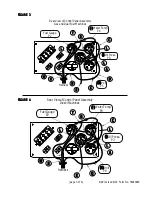

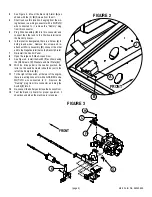

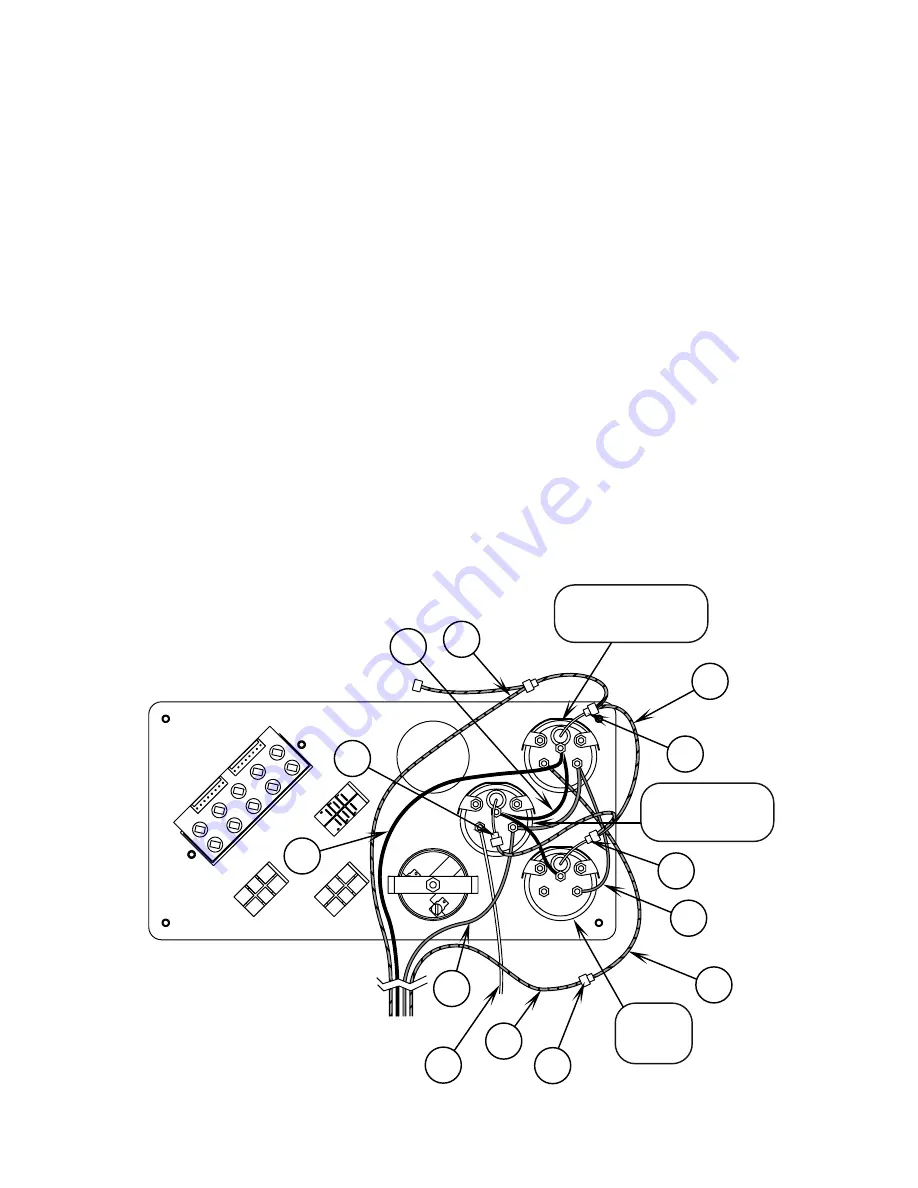

Mount the (3) gauges (H, I & J)

(H, I & J)

(H, I & J)

(H, I & J)

(H, I & J) in the holes that you cut in step 3 as shown in Figure 2, 3 or 4

Figure 2, 3 or 4

Figure 2, 3 or 4

Figure 2, 3 or 4

Figure 2, 3 or 4. Make sure the gauges are orientated

as shown.

6

66

66

Install the (3) (L)

(L)

(L)

(L)

(L) Terminal Tabs on the Black Wires for each gauge light.

7

77

77

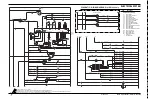

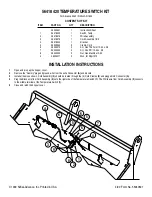

Install the (A, B, C, E & Q)

(A, B, C, E & Q)

(A, B, C, E & Q)

(A, B, C, E & Q)

(A, B, C, E & Q) Wire assemblies onto the gauges as shown in Figure 2, 3 or 4

Figure 2, 3 or 4

Figure 2, 3 or 4

Figure 2, 3 or 4

Figure 2, 3 or 4 respectively. When installing the wire

assembly (E)

(E)

(E)

(E)

(E) be sure to connect the smaller of the two ring terminals to the Oil Pressure Gauge. When installing the wire assembly

(Q)

(Q)

(Q)

(Q)

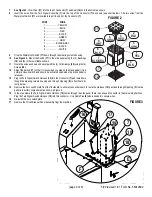

(Q) (only used on diesel machines) be sure to connect the smaller of the two ring terminals to the Water Temperature Gauge. Wiring

diagrams are also provided on the last page of this instruction sheet. Note: Wire assemblies (B)

(B)

(B)

(B)

(B) and (C)

(C)

(C)

(C)

(C) do not have to be wired

exactly as shown in the wiring diagrams (as demonstrated in Figures 2 & 3) as long as wires are all connected to the proper terminal

of each gauge they will work.

8

88

88

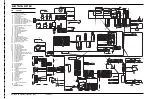

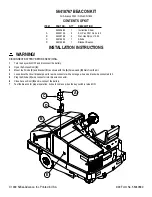

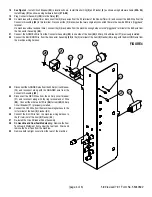

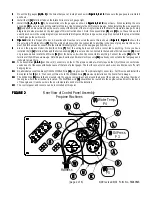

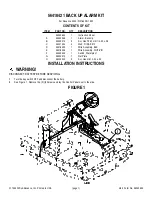

Figure 2

Figure 2

Figure 2

Figure 2

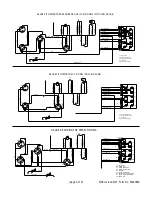

Figure 2 reflects a Propane Model. A Gasoline and Dual Fuel are wired the same this is shown in Figure 3

Figure 3

Figure 3

Figure 3

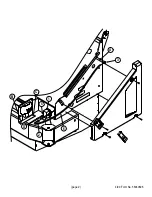

Figure 3. Figure 4

Figure 4

Figure 4

Figure 4

Figure 4 shows the

Diesel wiring. The Black Wire (S)

(S)

(S)

(S)

(S) from the wiring harness will not be connected to anything in the case of propane machines. You

must find this wire and connect it to the middle terminal (grd) of one of the new gauges from the kit.

9

99

99

Also on the propane model, the BLU/BLK Wire (T)

(T)

(T)

(T)

(T) from the wiring harness will not be connected to anything. Once you have

installed the (3) (L)

(L)

(L)

(L)

(L) Terminal Tabs and the Wire Assembly (C)

(C)

(C)

(C)

(C), this wire can be connected to the tab end of Wire Assembly (C)

(C)

(C)

(C)

(C). Next

on propane models locate the VIO wire (W)

(W)

(W)

(W)

(W) from the harness, it will not be connected to anything. Connect the wire (W)

(W)

(W)

(W)

(W) to the “IIIII”

terminal of the Oil Pressure Gauge. Note: On gas, dual fuel, and diesel machines wire (W)

(W)

(W)

(W)

(W) is already connected to the fuel gauge and

it should remain there.

10

10

10

10

10

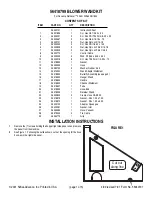

Wire Assemblies (A & B)

(A & B)

(A & B)

(A & B)

(A & B) each have (4) connectors on them. The propane model will only require that (3) of these connectors be

used on each of these assemblies because of the lack of a fuel gauge. The fourth connector on each wire can either be cut off or left

hanging loose.

11

11

11

11

11

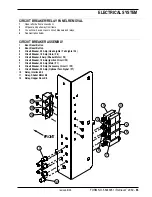

On all models except the diesel, find the VIO/BLK Wire (U)

(U)

(U)

(U)

(U) going to one of the indicator light connectors. Cut this wire and install the

Receptacle Tab (K)

(K)

(K)

(K)

(K) on it. Then connect this wire to the VIO/BLK Wire (D)

(D)

(D)

(D)

(D) previously installed on the Water Temp Gauge.

12

12

12

12

12

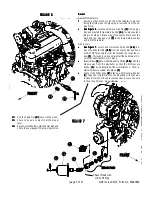

The White Wire (E)

(E)

(E)

(E)

(E) should then be routed into the engine compartment and around the back of the engine so it reaches the side of

the engine where the oil sender is located. The WHT/BLK wire (Q)

(Q)

(Q)

(Q)

(Q) should then be routed into the engine compartment to the back

of the engine so it reaches where the new temperature sender will be installed.

13

13

13

13

13

The control panel and console can be re-installed at this point.

A

(J)) Water Temp.

P4

(I)) Oil Press.

P3

(H)) Volt

P5

B

C

D

E

L

L

L

S

T

U

K

Rear View of Control Panel Assembly

Propane Machines

S

S

S

I

I

I

W

Harness

FIGURE 2

FIGURE 2

FIGURE 2

FIGURE 2

FIGURE 2

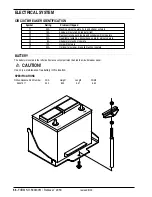

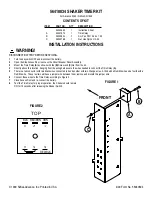

Summary of Contents for Advance Retriever 2060

Page 87: ...4 99 Form No 56040696 page 2 A 3 B C D 5 1 2 6...

Page 94: ...6 99 revised 3 00 Form No 56040702 page 2 5 3 2 6 6 5 3 4 1 2...

Page 111: ...9 00 Form No 56040733 page 2 of 3 Diesel H FRONT M K L N R W P O T S J Q O P U V FIGURE 1...

Page 128: ...PROGRAM PURPOSE and OBJECT ZENITH FUEL SYSTEMS Page 1 1 5 48 7 0 1 2 3 4 5 0 50...

Page 133: ...ZENITH FUEL SYSTEMS Page 5 1 5 0 50 A 50 4 4 B 8 6 A C D FIG 5 1...

Page 134: ...ZENITH FUEL SYSTEMS Page 5 2 6 5 8 0 8 2 0 2 0 2 E F 0 D 50 4 C D 5 5 5 5 6 6 2 0 6 FIG 5 2...

Page 139: ...Fuel Enrichment 4 6 6 50 5 5 6 A 50 5 0 0 ZENITH FUEL SYSTEMS Page 5 7...

Page 144: ...ZENITH FUEL SYSTEMS INC Page 5 12 3F 6 6 H J 3F FIG 5 19 6 G 6 FIG 5 20...

Page 147: ...ZENITH FUEL SYSTEMS Page 6 2 A A 1 6 FIG 6 1...

Page 148: ...ZENITH FUEL SYSTEMS Page 6 3 5 2 3 0 0 1 4 4 B 6 6 6 4 4 3 6 6 6 9 6 6...

Page 149: ...ZENITH FUEL SYSTEMS Page 7 2 8 2...

Page 150: ...ZENITH FUEL SYSTEMS Page 7 3 8 2...

Page 153: ...ZENITH FUEL SYSTEMS Page 9 3...

Page 160: ...ZENITH FUEL SYSTEMS Page 9 11 6 6 9 8 2...

Page 163: ...ZENITH FUEL SYSTEMS Page 9 14 6 6 9 8 Continued...