©Nilfisk-Advance Inc., F00018, 1/03

.pas

_____________________________________________________

TYPE: AX300, AX400

EU Overensstemmelseserklæring DK

Déclaration CE de conformité B, F

Tæpperensemaskine

Injecteur- extracteur

Maskinen er fremstillet i overensstemmelse med følgende

direktiver:

Cette machine a été fabriquée conformément aux directives

suivantes:

Maskindirektiv: 98/37/EØF

Réglementation machine: 98/37/CEE

EMC-direktiv: 89/336/EØF 92/31/EØF 93/68/EØF 98/13/EOF

Réglementation CEM:

89/336/CEE,92/31/CEE,93/68/CEE,98/13/CEE

Lavspændingsdirektiv: 73/23/EØF 93/68/EØF

Harmoniserede standarder: EN 60 335-2-67

Règlement basse tension: 73/23/CEE 93/68/CEE

Normes harmonisées: EN 60 335-2-67

EU Överensstämmelseförsäkran S, FIN

EG-conformiteitsverklaring NL, B

Golvvårdsmaskin

Sproei-extractie machine

Maskinen är tillverkad i överensstämmelse med följande

direktiver:

Deze machine is vervaardigd overeenkomstig de volgende

richtlijnen:

Maskindirektiv: 98/37/EEG

Machine richtlijn: 98/37/EEC

EMC-direktiv: 89/336/EEG 92/31/EEG 93/68/EEG 98/13/EEG

EMC-richtlijn: 89/336/EEC 92/31/EEC 93/68/EEC 98/13/EEC

Lågspänningsdirektiv: 73/23/EEG 93/68/EEG

Harmoniserade standarder: EN 60 335-2-67

Laagspanning richtlijn: 73/23/EEC 93/68/EEC

Geharmoniseerde normen: EN 60 335-2-67

EU Declaration of Conformity GB, IRL

Declaración de conformidad de la CEE E

Spray extraction machine

Máquina inyección/extracción

This machine was manufactured in conformity with the following

directives and standards:

Esta máquina ha sido fabricada en conformidad a las siguientes

normativas:

Machine Directive: 98/37/EEC

Normativa de la máquina: 98/37/CEE

EMC-directive: 89/336/EEC 92/31/EEC 93/68/EEC 98/13/EEC

Normativa EMC: 89/336/CEE 92/31/CEE 93/68/CEE 98/13/CEE

Low voltage directive: 73/23/EEC 93/68/EEC

Harmonized standards: EN 60 335-2-67

Normativa sobre baja tensión: 73/23/CEE 93/68/CEE

Normas armonizadas: EN 60 335-2-67

Dichiarazione di conformità - CEE I

EU Declaração de conformidade da CE P

Macchina ad estrazione

Máquina de injecção/extrcção

È prodotto in conformità alle disposizioni contenute nelle Direttive

del Consiglio dei Ministri:

Esta máquina foi fabricada em conformidae com as seguintes

directrizes:

M-direttiva: 98/37/EEC

Directriz de maquinaria: 98/37/CEE

EMC-direttiva: 89/336/EEC 92/31/EEC 93/68/EEC 98/13/EEC

Directriz EMC: 89/336/CEE 92/31/EEC 93/68/CEE 98/13/CEE

LV-direttiva: 73/23/EEC 93/68/EEC

Norme armonizzate: EN 60 335-2-67

Directriz de baixa voltagem: 73/23/CEE 93/68/CEE

Normas harmonizadas: EN 60 335-2-67

EG – Konformitätserklärung D, A

EU:n yhdenmukaisuudesta direktiiveihin FIN

Sprühextraktionsmaschine

Painehuuhtelukone

Diese Maschine wurde gemä

β

den folgenden Richtlinien

hergestellt:

On valmistettu noudattaen yhteisön määräämiä direktiivejä:

Maschinerichtlinie: 98/37/EWG

M-direktiivi: 98/37/CEE

EMV-Richtlinie: 89/336/EWG 92/31/EWG 93/68/EWG 98/13/EWG

EMC-direktiivi: 89/336/CEE 92/31/CEE 93/68/CEE 98/13/CEE

Niederspannungsrichtlinie: 73/23/EWG 93/68/EWG

Harmonisierte normen: EN 60 335-2-67

LV-direktiivi: 73/23/CEE 93/68/CEE

Yhdenmukaistetut standardit: EN 60 335-2-67

∆ηλωσηπροσαρµογης/συ

ó

ρϕωσης

EU GR

EL vastavusdeklaratsioon ET

Μηχανηµα καθαρισµου χαλιων ψεκασµου−αναρρ

ó

ϕησης

Pihustusmasin

Το µηχανηµα ιχει καταοκευαοτει ονµψωϖα µε τις παρακατω προσ

ιαγραψες:

Käesolev masin on valmistatud kooskõlas järgmiste direktiivide ja

standarditega:

Προσιαγραωη µηχανηµατος:

98/37/EEC

Masinadirektiiv: 98/37/EEC

Προσιαραψη−

EMC:

89/336/EEC,92/31/EEC,93/68/EEC,98/13/EEC

Elektromagnetilise sobivuse direktiiv: 89/336/EEC 92/31/EEC

93/68/EEC 98/13/EEC

Προσιαγραψη χαµηλης ταοεως: 73/23/

EEC

93/68/

EEC

Madalpinge direktiiv: 73/23/EEC 93/68/EEC

Εναρµονισµενα προτυπα:

EN 60 335-2-67

Ühtlustatud standardid: EN 60 335-2-67

Summary of Contents for AX 300

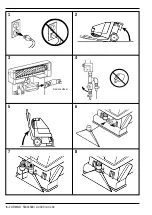

Page 7: ...6 FORM NO 56041590 AX 300 AX 400 1 2 7 8 5 6 3 4 Remove wheel ...

Page 8: ...FORM NO 56041590 AX 300 AX 400 7 1 2 3 4 5 6 7 8 Slide wheel on ...

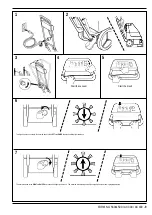

Page 11: ...10 FORM NO 56041590 AX 300 AX 400 8 9 10 Overlap 2 5 cm on each pass ...

Page 12: ...FORM NO 56041590 AX 300 AX 400 11 1 2 3 4 5 6 7 8 Turn machine OFF ...

Page 16: ......

Page 17: ......

Page 18: ......