20

- FORM NO. 56043025 / BA 700, 800, 1000 / 28LX, 32LX, 38LX / 280HD, 320HD, 380HD

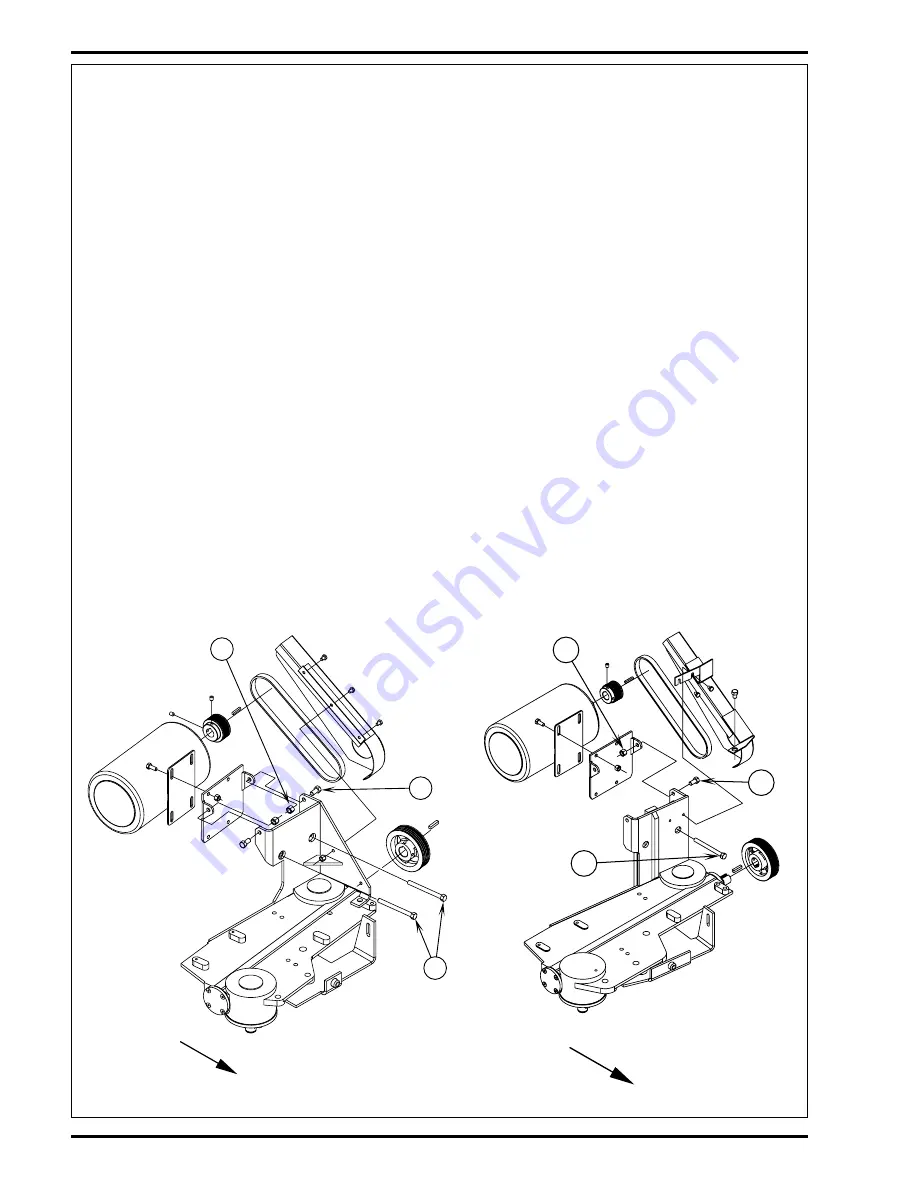

BRUSH DRIVE SYSTEM

F

FRONT

E

E

E

FRONT

F

E

4

Loosen the

(B)

Bolts and Nuts.

5

Loosen the

(C)

Lock Nuts and turn the

(D)

Bolts to adjust the belt tension. There should be about 3/32 inch (2 mm)

of belt deflection when 3-1/4 pounds of pressure is applied between the pulleys.

6

Follow steps 1-5 in reverse order to reassemble.

7

After the adjustment is complete, test to make sure the belt does not slip.

_____________________________________________________________________________

BELT TENSION ADJUSTMENT - BA 800, 1000 / 32, 38LX / 320, 380HD

1

Drain and tip the solution tank to the side of the machine.

2

See Figure 2. Loosen the

(E)

Bolts and Nuts.

3

Loosen the lock nuts and turn the

(F)

Bolts to adjust the belt tension. There should be about 3/32 inch (2 mm) of belt

deflection when 3-1/4 pounds of pressure is applied between the pulleys.

4

After the adjustment is complete, test to make sure the belt does not slip.

_____________________________________________________________________________________________________________________________

BELT TENSION ADJUSTMENT - BA 700 / 28LX / 280HD (continued)

FIGURE 2

BA 800 / 32LX / 320HD

BA 1000 / 38LX / 380HD