FORM NO. 56041587 - Hydro-Retriever

™

3800, 2042 / BR 1100, 1100C, 1100C-XL - 19

ENGLISH / 19

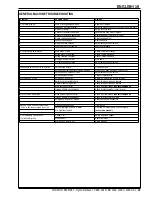

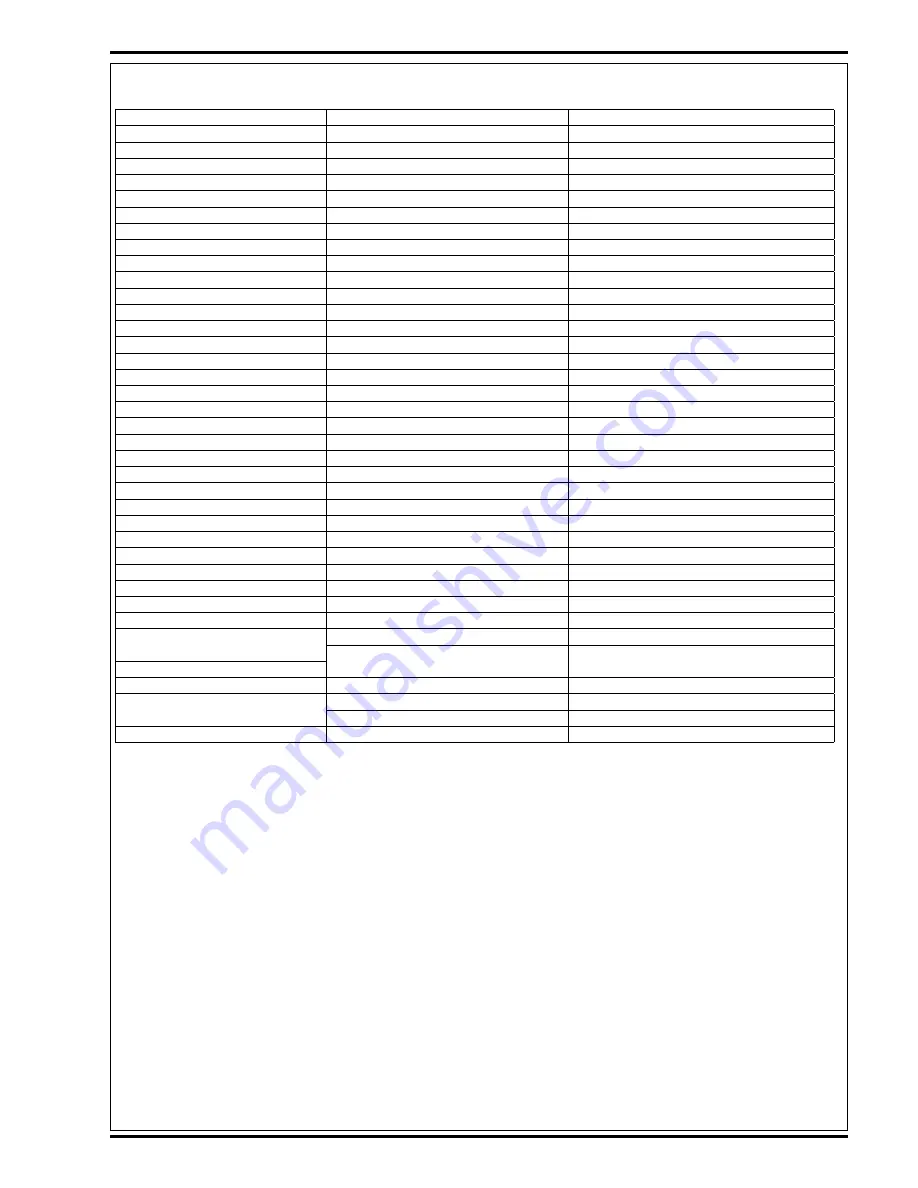

GENERAL MACHINE TROUBLESHOOTING

Problem

Possible Cause

Remedy

Poor water pick-up

Worn or torn squeegee blades

Reverse or replace

Squeegee out of adjustment

Adjust so blades touch fl oor evenly across entire width

Recovery tank full

Empty recovery tank

Recovery tank drain hose leak

Secure drain hose cap or replace

Recovery tank cover gasket leak

Replace gasket / Seat cover properly

Debris caught in squeegee

Clean squeegee tool

Vacuum hose clogged

Remove debris

Using too much solution

Adjust solution control valves

Foam fi lter cover not seated

Seat cover properly

Poor scrubbing performance

Worn brush or pad

Rotate or replace brushes

Wrong brush or pad type

Consult Nilfi sk-Advance

Wrong cleaning chemical

Consult Nilfi sk-Advance

Moving machine too fast

Slow down

Not using enough solution

Adjust solution control valves

Inadequate solution fl ow or no solution

Solution tank empty

Fill solution tank

Solution lines, valves, fi lter or trough clogged

Flush lines, trough and clean solution fi lter

Solution control valves not open

Adjust solution control valves

Solution solenoid valve

Clean or replace valve

Machine does not run

Emergency stop switch

Rotate the stop switch knob to release

Battery charger port interlock

Check for open circuit and replace

Operator seat safety switch

Check for open circuit and replace

Main system controller

Check error fault codes (see service manual)

Tripped 10 Amp circuit breaker

Check for electrical short circuit & reset

No FWD/REV wheel drive

Drive system speed contoller

Check error fault codes (see service manual)

Tripped 80 Amp circuit breaker

Check for drive motor overload

Emergency stop switch tripped

Reconnect battery connectors

Vacuum shuts off and display shows

“FULL” when recovery tank is not full

Plugged squeegee hose

Clear debris

Vacuuming large amounts of water

at a high travel speed

Slow down or disable auto shut-off feature

(see service manual)

Poor Sweeping Performance

(Cylindrical System)

Hopper Full

Empty and clean hopper

Brushes worn

Replace brushes

Bristles have taken a set

Rotate brushes