54

- FORM NO. 56043058 Hydro-Retriever™ 3800 / 2042 / BR 1100

ELECTRICAL SYSTEM

A

B

IN

OUT

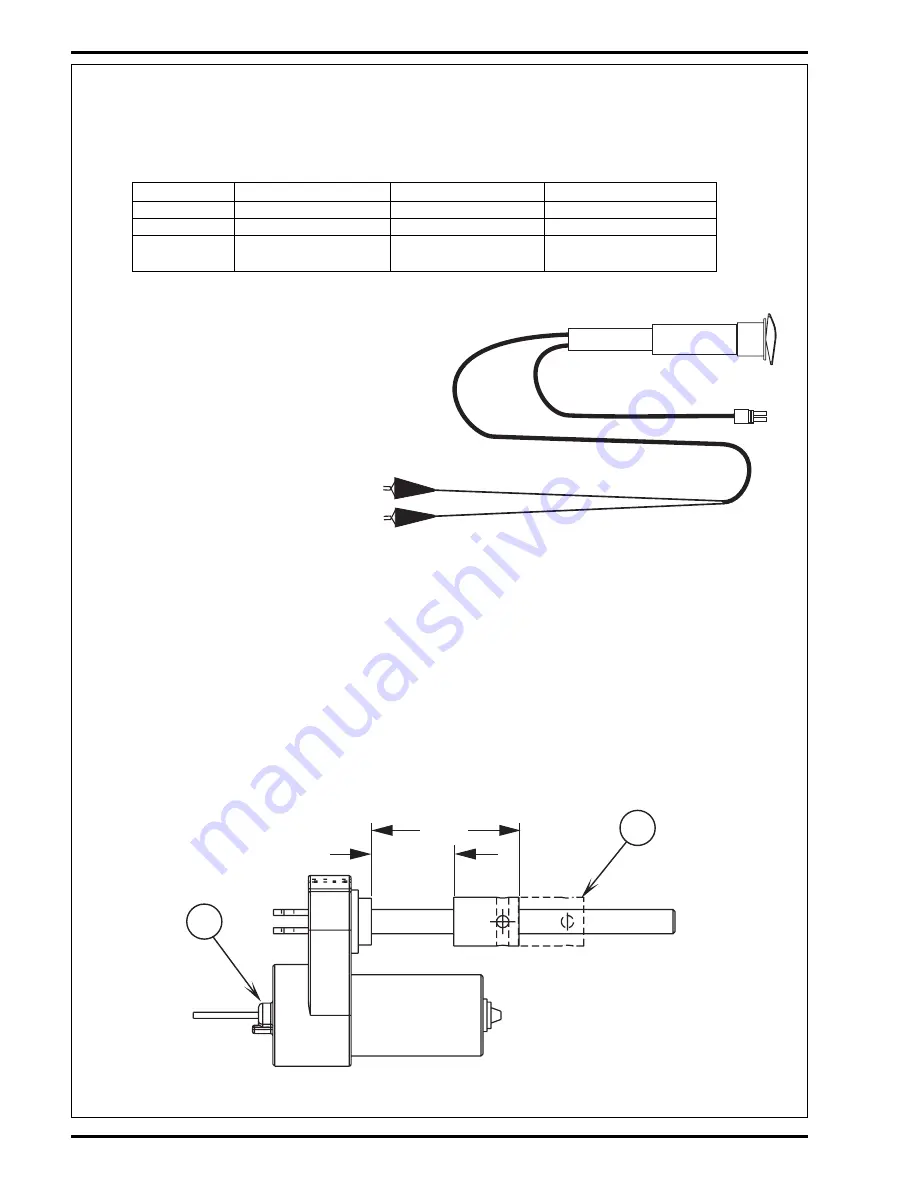

ACTUATOR DRIVE NUT ADJUSTMENT

This manual section explains the steps for adjusting the drive nut settings for the machine’s two lift actuator motors. Reference the chart below

to find the IN & OUT dimensional specification for the specific actuator motor needing adjustment.

Part #

Actuator Motor

Drive Nut IN Position

Drive Nut OUT Position

56393303

Scrub Brush Lift

1/2" (13 mm)

4-1/4" (108 mm)

56393303

Squeegee Lift

2-3/8" (60 mm)

4-1/4" (108 mm)

56393303

Side Broom Lift

1" (25 mm)

4" (101 mm)

(2042 / BR 1100C-XL only)

General Instructions for All Actuator Motors

1

See Figure 2. This shows the special actuator

power cord adapter

(PN 56407502)

that is needed

to connect the machine’s battery pack and actua-

tor motor for setting the drive nut limit settings.

2

Open the machine battery compartment and dis-

connect the battery connector. The battery pack

is needed to power the lift actuator motor to

properly set the IN & OUT limit switches.

3

Connect the actuator motor to be tested to the

power cord adapter end. Then connect the alliga-

tor clips from the cord adapter (red clip to the

positive and black to negative) to battery connec-

tor or battery posts. The rocker switch is used to

change the motor rotation in setting the correct

drive nut dimension.

Instructions for Squeegee and Side Broom Lift Actuator Drive Nut Adjustment

4

See Figure 3. Hold onto the Actuator Drive Nut

(A)

and press the rocker switch to run the drive motor and retract the nut towards the motor

housing (its IN limit).

5

Measure the position of the drive nut on the actuator shaft. Manually turn the plastic drive nut to the IN position as shown in the chart.

6

Hold the drive nut then press the adapter cord rocker switch to run the drive motor to the OUT position (wait until the motor stops).

7

Measure the position of the drive nut on the shaft and compare the measurement with the OUT position shown in the chart.

8

When the measurement doesn’t match the dimension shown in the chart it is necessary to remove the Adjuster Cover

(B)

and adjust the

Out position.

9

To increase the travel of the drive nut, turn the adjuster clockwise. To decrease the travel of the nut, turn the adjuster counter clockwise.

NOTE: Use a 5/16" wrench to turn the adjuster. Each click of the adjuster will change the nut travel 1/16 inch (1.6 mm).

10

After each adjustment, hold the drive nut, run the actuator IN & OUT and check both dimensions. After checking that the drive nut limits

are set correctly then replace the adjuster cover.

Service Tip Note:

Use the above power cord adapter to help position the drive nut (in

or out) for ease in actuator motor installations.

FIGURE 2

FIGURE 3

revised 12/02