56043021

- 260, 32, 38, 320, 380

SOLUTION SYSTEM

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

MAINTENANCE

The solution system should be flushed every day to prevent a build-up of soap residue in the solution valve.

To flush the solution system . . .

1

Park the machine near a floor drain and open the solution valve.

2

When the tank is empty, close the solution valve and put about 2 inches (5 cm) of clean, warm water in

the solution tank.

3

Move the solution lever to the full-on position, and allow all of the water to drain through the solution

valve.

4

Close the solution valve before refilling the solution tank.

5

Check to make sure that the solution tank screen is not plugged (32, 38, 320, 380).

6

The solution filter is flushed when ever the solution tank is drained through the drain hose (260).

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

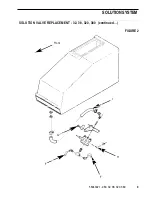

SOLUTION VALVE REPLACEMENT - 260

1

Drain both the solution and recovery tanks.

2

Tip the solution tank forward and remove the recovery tank from the machine.

3

Remove the vacuum motor hose for easier access to the solution valve.

4

See Figure 1. Disconnect hose “A” from the top of solution valve “B”.

5

Disconnect solution cable “C” from the solution valve arm (do not loose the bushing).

6

Remove the (2) “D” bolts and nuts holding the solution valve to its mount.

7

Disconnect the (2) “E” solution hoses and remove solution valve “B” from the machine.

8

Remove all of the fittings from the old solution valve and install them on the new one.

9

Follow steps 1-7 in reverse order to reassemble.

10

Test for leaks and proper operation.

6