CAUTION:

This Nilfisk vacuum cleaner is not to be used in explosion-hazardous areas, as

serious injury could result.

Under no circumstances may this vacuum cleaner be used safely for the collection of hazardous

or toxic materials unless equipped with a HEPA filter. Be sure to install the HEPA filter according

to Nilfisk’s written instructions.

Do not use this cleaner for the removal of hazardous substances unless you are licensed and/or

certified for this work by the all authorities having jurisdiction.

EMPTYING:

If this vacuum cleaner is used to collect hazardous material, do not attempt to open

or empty its contents without personal protective clothing and respiratory protection. This

procedure must be completed in a contained environment. Contact with the cleaner, filters and

all other accessories used when picking-up hazardous materials must be handled according to

federal (EPA, OSHA), state and local regulations valid for the vacuumed substance.

ATTENTION EMPLOYER:

Please ensure these instructions for Use are made available and

understood by your employees or any other persons who may use this equipment.

To list all toxic and hazardous materials would be beyond the scope of these instructions. It is

the Employer’s responsibility to identify, for Employee’s and others’ information, hazardous or

toxic materials which may be collected by this equipment. Such information must be

communicated to your Employees and other potential users of this equipment.

Nilfisk-Advance America Inc.

300 Technology Drive

Malvern, PA 19355

Tel: 1.610.647.6420

Fax: 1.610.647.6427

www.pa.nilfisk-advance.com

e-mail:

email@nilfisk-advance.com

Instructions/Spare Parts Manual

Nilfisk Model GWD255

Drum Top Vacuum

Summary of Contents for GWD 255

Page 2: ......

Page 3: ......

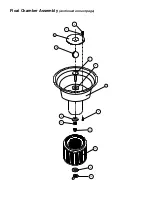

Page 9: ...Parts Explosion Motor head Assembly...

Page 13: ...Float Chamber Assembly continued on next page 1 3 4 2 9 10 11 12 9 13 7 8 6 5...