General Information

BEFORE CONNECTING THE MACHINE TO A POWER SUPPLY,

check the electrical rating

plate located on the back of the motor head to see if the rated voltage agrees within 10% of the

voltage available.

DO NOT OIL

the motor in this vacuum cleaner. It is permanently lubricated and sealed.

DO NOT OPERATE

the vacuum cleaner without any filters. The Dry Filter, Wet/Dry Cartridge

Filter or HEPA filter should be installed to prevent dirt and dust from entering the motors.

This machine is equipped with a thermal breaker to protect the motor and other vital machine

parts from overheating. Should this breaker open, you will have to wait at least 5-10 minutes

before starting the machine again. You must reset the machine by switching the ON/OFF button.

While you are waiting, switch the machine off and unplug it. Check the hose and filters to be sure

that nothing is blocking the flow of air through the machine.

Service Information

UNPLUG THE MACHINE BEFORE PERFORMING ANY MAINTENANCE.

To obtain consistent performance over the life of your vacuum, read through these instructions

and keep them handy for future reference. If you require service, contact the dealer from whom

the vacuum was purchased, or the local authorized Service Station. Always refer to your Service

Station for complete service information. For prompt and complete service information, always

refer to the model, type and serial number indicated on the rating plate on the back of the motor

head.

IMPORTANT

The machine is equipped with a specially designed cord which if damaged, must be replaced by

a cord of the same type. This cord is available at authorized service centers and dealers and

must be installed by trained personnel.

Summary of Contents for GWD 255

Page 2: ......

Page 3: ......

Page 9: ...Parts Explosion Motor head Assembly...

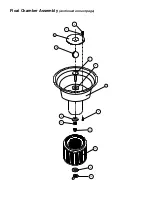

Page 13: ...Float Chamber Assembly continued on next page 1 3 4 2 9 10 11 12 9 13 7 8 6 5...