2

II. MACHINE PREPARATION

A. Adding Oil

The Burnisher is shipped by

overland freight with the correct amount of oil in the engine. Air freight

shipments require the

machine to be shipped without oil.

The machine is also shipped with the battery disconnected.

When filling a "dry" burnisher or changing oil,

add no more than 1.5 quarts (or 1.75 quarts when the oil filter is

changed)

then check the dip stick in the fill cap. Add oil if necessary but

DO NOT OVERFILL! ALWAYS CHECK OIL

BEFORE USING THE MACHINE.

Refer to Engine Owner's Manual.

IMPORTANT:

WHEN CHECKING OIL ON KAWASAKI MODELS, REMOVE OIL FILLER CAP AND CLEAN

DIPSTICK WITH CLEAN CLOTH, THEN INSERT DIPSTICK INTO TUBE WITHOUT SCREWING IN. THEN

CHECK OIL LEVEL.

ALWAYS MAKE SURE THE MACHINE IS SITTING LEVEL WHEN CHECKING OIL.

B. Connecting the Battery

Connect the

RED

positive battery cable

FIRST.

Connect the

BLACK

negative battery cable

LAST.

C. Adjusting the Handle

The burnisher handle adjusts for comfort and optimum control. Height may be changed to suit the individual operator.

(See page 8)

D. Filling the Safety Fill Fuel Cylinder

Nilfisk-Advance uses the 20 lb. capacity aluminum safety fill cylinder which meets the D.O.T. 4E240 standards. These

cylinders are also listed by U.L. Filling should ONLY be done by a qualified propane dealer.

FILL THROUGH THE STOP

FILL VALVE ONLY.

(See page 9) A properly filled cylinder should not exceed 80% of the rated capacity.

DO NOT

attempt safety fill cylinder repair. Return the cylinder to your propane dealer if repair is necessary. Please note that

D.O.T. regulations prohibit shipping of cylinders after the cylinder has been filled with propane.

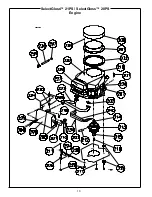

E. Installing the Safety Fill Fuel Cylinder

Align the slot in the top flange of the cylinder with the locating pin on the machine. Strap the safety fill cylinder in place by

clamping the toggle assembly to the cylinder band. Adjust the toggle assembly by screwing in or out in order to keep the

tank firmly secured. Connect the fuel hose coupling to the service valve by turning right (clockwise).

HAND TIGHTEN

ONLY.

Make sure coupling is not cross threaded and check for leakage by noting any odors of propane immediately after

cylinder is connected. (It is sometimes easier to install if the connection to the service valve is made before strapping the

cylinder in place.)

TO REMOVE THE SAFETY FILL CYLINDER, reverse above procedure. Always connect or change cylinders in a well

ventilated area.

III. OPERATING INSTRUCTION

A. Starting Instructions

1. Check oil and fuel levels.

2. Check and clean engine air filter.

NEVER RUN CONTINUOUSLY FOR MORE THAN 1 HOUR WITHOUT CLEANING OR CHANGING ENGINE DUST

FILTER.

(See "Scheduled Maintenance")

3. Check carburetor air filter. Change if necessary.

(see "Scheduled Maintenance")

4. Turn propane service valve counterclockwise to open.

5. Allow machine to tilt backward (pad off floor) and move the throttle to the

SLOW

position.

6. Engage starter by turning the key-switch to the starting position for approximately 5 seconds. If the machine fails to start,

let the ignition switch return to the run position (Do not turn off). Wait approximately 5 seconds and try again for another

5 seconds. (

NOTE:

Do not engage starter for more than 10 seconds. Allow a 60 second cool-down period for each 10

second start-up cycle.)

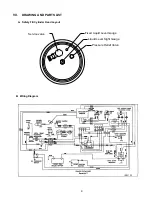

7. After engine starts, a GREEN light will flash for a 3 minute warm-up cycle of the SmartAir system. (The machine may be

operated during this warm-up period.) After the warm-up cycle the green light will remain on steady as long as the

machine is running safely.