5 - FORM NO. 56041466 / SELECTLINE 17TS / 20TS

INTRODUCTION

This manual will help you get the most from your Kent SelectLine. Read it

thoroughly before operating the machine.

This product is intended for commercial use; polishing, spray buffing, scrubbing,

stripping and rotary carpet shampooing.

PARTS AND SERVICE

Repairs, when required, should be performed by your Authorized Kent Service

Center, who employs factory trained service personnel, and maintains an

inventory of Kent original replacement parts and accessories.

Call the KENT DEALER named below for repair parts or service. Please specify

the Model and Serial Number when discussing your machine.

(Dealer, affix service sticker here.)

NAME PLATE

The Model Number and Serial Number of your machine are shown on the

Nameplate on the bottom of the machine. This information is needed when

ordering repair parts for the machine. Use the space below to note the Model

Number and Serial Number of your machine for future reference.

MODEL NUMBER

SERIAL NUMBER

UNCRATE THE MACHINE

When the machine is delivered, carefully inspect the shipping carton and the

machine for damage. If damage is evident, save the shipping carton so that it can

be inspected. Contact the Kent Customer Service Department immediately to file

a freight damage claim.

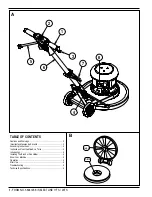

(A) - KNOW YOUR MACHINE

1

Operator Hand Grips

2

Switch Lever Safety Lock Button

3

Switch Levers - Squeeze - ON / Release - OFF

4

Handle Adjustment Lever

5

Power Cord

6

Operator Handle

7

Power Cord Hook

8

LO/HI Speed Selector Switch

WARNING!

This machine contains moving parts. To reduce the risk of injury,

always unplug the power cord before servicing.

(B) - INSTALLING THE BRUSH OR PAD HOLDER

Align the lugs with the corresponding slots in the brush or pad holder and turn the

brush or pad holder counterclockwise to lock it in place. To remove brush/pad

holder, give it a quick, hard turn clockwise.

CAUTION!

Using the wrong brush or pad on this machine can damage the floor or overload

the motor.

OPERATION

1

Unwrap the Power Cord and plug it into a properly grounded outlet.

2

Select the desired speed setting; Low-190 rpm, High-300 rpm.

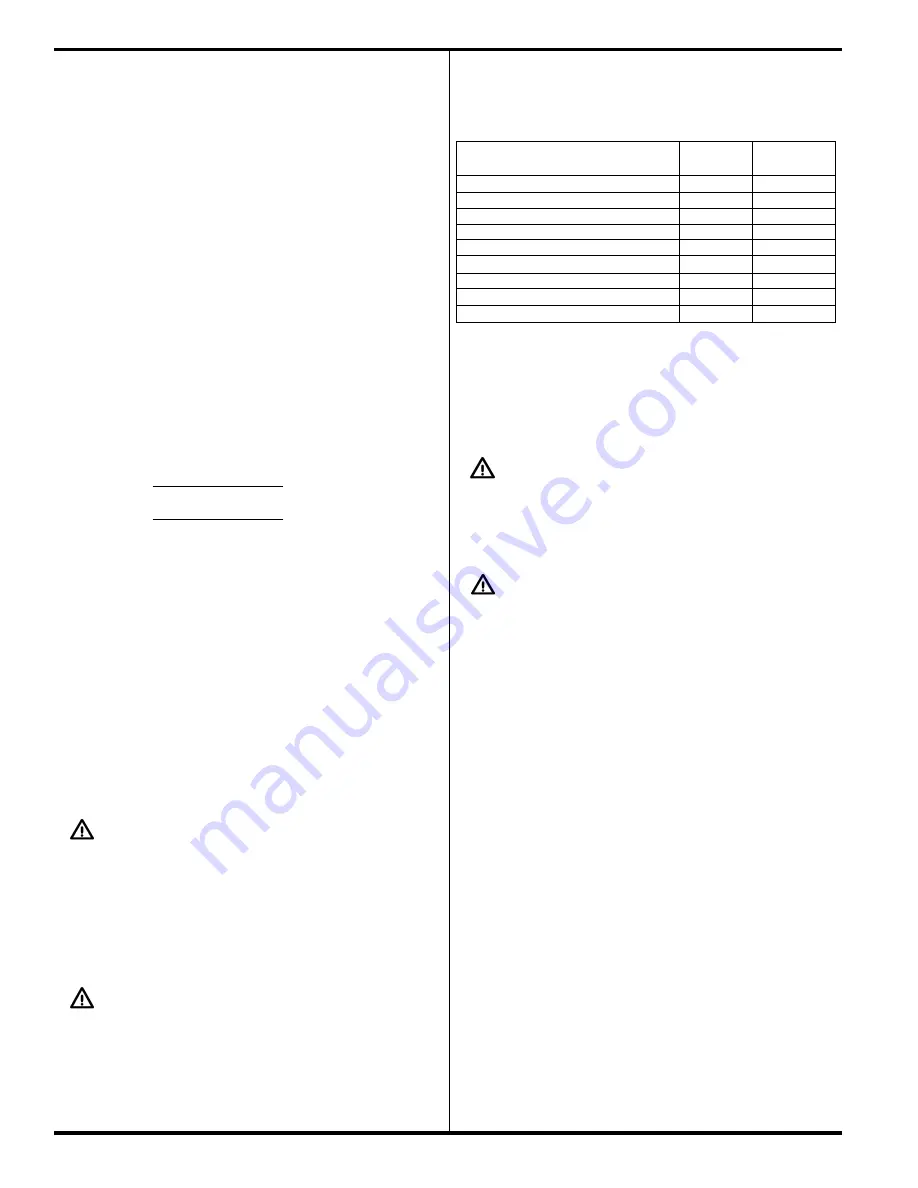

TWO SPEED SELECTLINE SPEED SELECTOR GUIDE

Cleaning Application

Low Speed

High Speed

175 rpm

275 rpm

Carpet Shampooing

X

Stripping

X

Heavy Scrubbing

X

Bonnett Cleaning

X

Light Scrubbing

X

X

Carpet Shampooing (w/Soft-Touch Brush)

X

X

Spray Cleaning / Buffing

X

Buffing

X

Polishing

X

NOTE: Speed should not be changed while in operation. To change

speed, shut off machine, select desired speed setting and repeat steps

2-5.

3

Loosen the Handle Adjustment Lever (4) by pulling up on the bottom of

the lever. Move the Operator Handle downward until your arms are

almost straight. Then step down on top of the lever to lock it.

4

Lift the Handle until the brush (or pad) is flat against the floor.

WARNING!

Be prepared to control the machine as soon as the motor starts.

Just a slight up or down movement of the Handle will make the

machine move from side to side. Raise the Handle to go right.

Lower the Handle to go left.

CAUTION!

Immediately start moving the machine back and forth. Keep the

machine moving while the motor is running to avoid damage to the

floor or carpet.

5

Hold one of the Operator Hand Grips (1) firmly, push the Safety Lock

Button (2) and then compress the Switch Levers (3) to start the motor.

NOTE: When the dual controlled switch levers are released, the machine

shuts off immediately.

NOTE: When spray buffing, check the pad every 15 minutes for dirt and

wax build-up. If the pad is dirty, turn it over to expose the clean side or

install a clean pad.