ENGLISH

INSTRUCTIONS FOR USE

16

SC250, Scrubtec 334 - 9100001614

07/2016

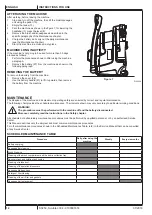

TROUBLESHOOTING

Trouble

Possible Cause

Remedy

The motors do not turn on; no LED

turns on.

The battery is completely discharged.

Charge the battery.

Change the battery.

Switch panel broken.

Replace the switch panel. (*)

Broken grip handle sensors.

Replace the grip handle sensors. (*)

The battery LEDs flash while working

Brush motor overload.

Reduce the brush pressure on the floor.

There are foreign materials (tangled threads, etc.)

preventing the brush from rotating.

Clean the brush hub.

While running, the machine is noisy

and it vibrates.

Deformed brush bristles.

Wash the brush with hot water to restore the bristles.

Do not leave the machine parked without the

transport/parking wheels.

The recovery water vacuuming is

insufficient.

The recovery tank is full.

Empty the tank.

The squeegee bars are dirty or the blades are worn

or damaged.

Clean and check the squeegee bars.

The recovery water conduit is dirty.

Clean the conduit with running water.

The air filter is dirty.

Clean the filter.

The solution flow is insufficient.

The solution push-button LEDs flash.

The solution dispensers are clogged.

Clean the solution dispensers.

Solution tank empty.

Fill the tank.

The solution filter is dirty.

Clean the filter.

Water pump fault.

Replace the pump. (*)

The squeegees leave marks on the

floor.

There is debris under the squeegee blades.

Remove the debris.

The squeegee blades are worn, chipped or torn.

Replace the blades.

Debris collection tray full.

Empty the tray.

(*)

This maintenance procedure must be performed by an authorised Nilfisk Service Center.

For further information refer to the Service Manual, available at any Nilfisk Service Center.

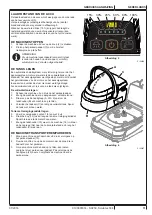

SCRAPPING

Have the machine scrapped by a qualified scrapper.

Before scrapping the machine, remove and separate the following materials, which must be disposed of properly according to the

Law in force:

–

Cylindrical brush

–

Plastic hoses and components

–

Electrical and electronic components (*)

(*)

Refer to the nearest Nilfisk Center especially when scrapping electrical and electronic components.

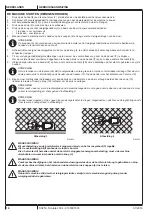

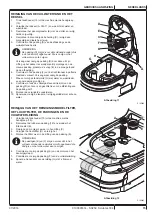

Machine material composition and recyclability

Type

Recyclable

percentage

% weight SC250, Scrubtec 334

Aluminium

100 %

13 %

Electric motors - various

29 %

28 %

Ferrous materials

100 %

6 %

Wiring harness

80 %

5 %

Liquids

100 %

0 %

Plastic - non-recyclable material

0 %

1 %

Plastic - recyclable material

100 %

36 %

Polyethylene

92 %

9 %

Rubber

20 %

3 %