129

40 - Recovery System

Vacuum Suction Test

Use this procedure to verify that the vacuum system is performing within factory specifications. This

procedure can also be used to isolate the cause of a vacuum problem between a clog or leak It is a two-part

procedure that verifies both static pressure and flow rate. This procedure requires a vacuum gauge (PN

56205281), a piece of 2" PVC (or similar) tube, a 1" hole saw, and some duct tape (or similar, for a seal)

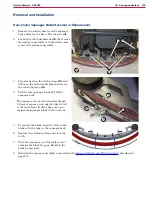

1 Remove the suction hose

(A)

from the squeegee

and then turn on the vacuum

2 Place the vacuum gauge

(B)

on the hose so the

taper

(C)

seals against the end of the hose

3 Record the vacuum pressure reading from the

gauge This is the static pressure

4 Turn the vacuum off while constructing and

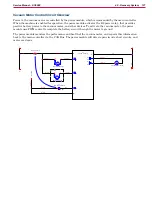

fitting the PVC restricter tube

(D)

5 Cut a piece of 2" PVC approximately 6" long, and

clean off the burs The outer diameter of the tube

should be close to, but not larger than 2½"

6 Drill a 1" hole

(E)

approximately in the middle of

the PVC tube, and clean off the burs

7 As necessary, wrap duct tape around the tube so

it fits snugly in the end of the end of the suction

hose with no leaks

8 Turn the vacuum on and place the vacuum gauge

on the restricter tube

9 Record the vacuum pressure reading from the

gauge. This is the restricted flow pressure.

Results Summary

The first part of this procedure determined the static pressure of the vacuum system, and the second part

determined the flow rate (by calculation). The flow rate through a restriction is determined by the pressure

differential across the restriction These two parameters may be used to determine if the vacuum system is

functioning properly, and may also be used to isolate a possible cause for a problem

•

If the static pressure is at least 57 inches H

2

O, then the vacuum motor(s) are functioning properly and

there are no significant leaks in the system.

• If the 1” restricted flow pressure is at least 20 inches H

2

O, then there are no significant clogs in the

system

• If both parameters are below specifications, then one or both vacuum motors may be failing, or there may

be a significant leak in the system.

B

C

A

D

E