120

38 - Squeegee System

Actuator Limit Adjustment

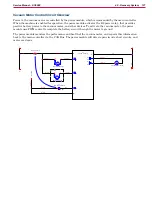

The power module commands the actuator to raise

or lower, but the actuator itself determines when

it should stop moving This is accomplished by two

cam lobes and two micro switches (limit switches)

The lower cam is not adjustable, so the lower limit

is adjusted by rotating the leadscrew nut Then the

upper limit is adjusted by turning the cam lobe until

the actuator stops at the correct height

To make the adjustment, you will need to manually

power/control the actuator If you don’t have the

described on page 125, you can

use the Squeegee Lift Output Test described on

Just note that if you use the Output Test, you

may periodically cause a controller fault, and have to

reset the machine For simplicity, this procedure is

written for the test kit method

This procedure is typically performed as part of

replacing the actuator If the actuator is not already removed from the machine, then remove it following the

procedure on

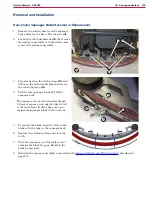

1 Connect the tester

(A)

to the positive and negative terminals of the battery

2 Using the adapter cable

(B)

, connect the tester to the actuator

3 While preventing the actuator leadnut

(E)

from turning, use the switch

(C)

, extend the actuator until it

stops

4 Measure the distance between the actuator

gearbox at

(G)

and the top of the leadnut at

(F)

5 Manually turn the leadnut until this

distance is 68mm (2.7”).

CAUTION: If while retracting the actuator

with the “Output Test”, it

appears the leadnut is going

to crash into the actuator

housing, let go of the leadnut

and let it spin.

6 While holding the leadnut from turning,

retract the actuator until it stops

7 Measure the retracted distance between

(G&F)

. The target is 23mm (.93”).

C

B

A

68mm Extended

23mm Retracted

E

G

F